The 10126-3000PE is part of the 3M 101 Series Mini D Ribbon connector family, offering reliable data and signal transmission in compact environments. As a 3M 101 Series Mini D Ribbon connector, it is a top choice among engineers and technicians for supporting high-density connections while maintaining exceptional performance. The precise engineering of the 10126-3000PE makes it indispensable for modern electronic systems that require both space efficiency and dependable connectivity.

3M 101 Series Mini D Ribbon connector some inventory

10114-3000 VE,10120-3000 VE,10126-3000 VE,10136-3000 VE

10150-3000 VE, 10114-3000 PE, 10120-3000 PE,

10126-3000 PE, 10136-3000 PE, 10150-3000 PE

Key Takeaways

-

The 10126-3000PE is a compact, high-density connector designed for reliable data and signal transmission in small spaces.

-

It features gold-plated contacts and a metal shell that protect against corrosion and electromagnetic interference, ensuring strong signal quality.

-

The connector supports easy installation and removal with a quick-release latch and does not require special tools.

-

It works well in harsh environments, handling temperatures from -55°C to 105°C and resisting vibration and twisting.

-

The 10126-3000PE is widely used in industries like automation, telecom, medical devices, and test equipment for its durability and dependable performance.

What is 10126-3000PE?

Definition

The 10126-3000PE is a 3M Mini Delta Ribbon (MDR) half-pitch I/O connector. This connector uses a 0.050-inch contact pitch, which means the pins are spaced closely together. Engineers often choose this connector for high-density input and output applications. The 10126-3000PE features a rugged metal shell and a quick-release latch, making it reliable in demanding environments.

The 10126-3000PE stands out because it meets strict industry standards for safety and performance. Its insulation uses glass-reinforced polyester (PBT), and it holds a UL 94 V-0 flammability rating. This ensures the connector can handle tough conditions without compromising safety.

Here is a table that highlights the main technical specifications:

|

Specification/Feature |

Details/Value |

|---|---|

|

Interconnect System Design |

Half-pitch Mini Delta Ribbon (MDR) |

|

Contact Pitch |

0.050 inch (half-pitch) |

|

Application Suitability |

High-density input/output |

|

Insulation Material |

Glass-reinforced polyester (PBT) |

|

Flammability Rating |

UL 94 V-0 |

|

Plating |

Minimum 30 microinches gold in wiping area |

|

Current Rating |

1 Amp |

|

Temperature Rating |

-20°C to +85°C |

|

Cable Compatibility |

3M pleated foil cable for controlled impedance |

|

Mechanical Features |

Rugged metal junction shell, quick release latch |

|

Accessories |

Conductive elastomer for shield continuation |

Purpose

The main purpose of the 10126-3000PE is to provide a secure and efficient way to transmit data and signals between electronic devices. This connector supports both male-to-female cable assemblies and extension or interconnection in MDR systems. It mates with popular 3M MDR 26-position receptacles, making it a flexible choice for many setups.

-

Engineers use the 10126-3000PE in systems that require reliable connections in small spaces.

-

The connector supports a current rating of 1 Amp and operates in temperatures from –20°C to +85°C.

-

Its gold-plated contacts ensure strong signal integrity over time.

-

The quick-release latch allows for easy installation and removal, which saves time during maintenance.

The 10126-3000PE has become an industry standard for high-density connections. Its design and materials help maintain signal quality and device safety. Many industries rely on this connector for its proven performance and compatibility with other MDR components.

10126-3000PE Features

Physical Specs

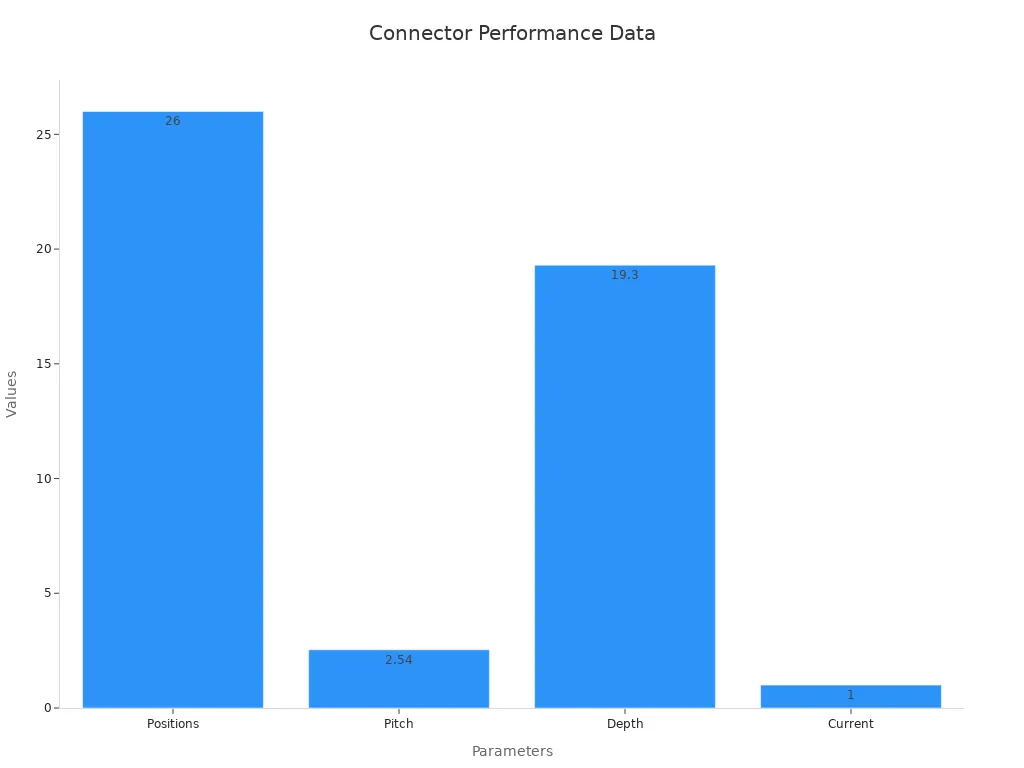

The 10126-3000PE connector stands out for its compact size and precise engineering. It uses a 26-position pin layout, arranged in two rows, which allows for high-density connections in limited spaces. The connector features a 0.050-inch (2.54 mm) pitch, meaning the pins are closely spaced for efficient use of space. The housing uses high-temperature plastic, making it suitable for harsh environments. Gold plating on the contacts helps prevent corrosion and ensures a reliable electrical connection.

The following table summarizes the key physical specifications:

|

Specification |

Value |

Description/Notes |

|---|---|---|

|

Number of Positions |

26 |

Pin count of the connector |

|

Pitch |

2.54 mm |

Distance between adjacent pins |

|

Number of Rows |

2 |

Connector has two rows of pins |

|

Depth |

19.3 mm |

Front-to-back measurement of the connector |

|

Gender |

Male |

Connector has protruding pins for mating with female connectors |

|

Orientation |

Straight |

Alignment of the connector pins |

|

Contact Finish |

Gold |

Gold plating on contacts for reliable electrical connection and corrosion resistance |

|

Housing Material |

High-temperature plastic |

Durable plastic housing suitable for harsh environments |

This design makes the connector ideal for devices where space is limited but performance cannot be compromised.

Electrical Specs

The electrical specifications of the 10126-3000PE ensure safe and stable operation in demanding applications. The connector supports a maximum current rating of 1 ampere, which is suitable for most data and signal transmission needs. It operates reliably within a temperature range from -55°C to 105°C. The connector works with wire sizes from AWG24 to AWG30, making it compatible with a variety of cable types. Solder cup termination allows for secure and lasting connections.

The table below highlights the main electrical characteristics:

|

Specification Aspect |

Details |

Notes/Conditions |

|---|---|---|

|

Rated Current |

Maximum allowable current between coupled contacts |

|

|

Rated Voltage |

150 VAC / 200 VDC or less |

Maximum continuous AC/DC voltage under rated ambient temperature |

|

Ambient Temperature Range |

-55°C to +85°C |

Usable temperature range under maximum load |

|

Compatible Wire Size |

AWG24 to AWG30 (0.2 mm² to 0.05 mm²) |

For solder type male connector; flat cables not compatible; pay attention to cable outer diameter |

|

Contact Resistance |

Initial ≤ 35 mΩ; after testing ≤ 25 mΩ |

Measured with 1.5 mA current and 20 mV release voltage; includes bulk resistance of contacts |

|

Insulation Resistance |

≥ 500 MΩ |

Measured after applying 500 VDC between adjoining contacts for 1 minute |

|

Voltage Resistance |

No arc or dielectric breakdown |

Tested by applying 500 VAC between adjoining contacts for 1 minute; leakage current ≤ 1 mA |

These features help maintain signal integrity and protect connected devices from electrical faults.

Shielding and Durability

Engineers designed the 10126-3000PE with robust shielding to reduce electromagnetic interference (EMI). The connector uses a metal shell that provides extra protection against noise and signal loss. This shielding is especially important in environments with many electronic devices operating close together. The gold-plated contacts resist corrosion and wear, which extends the connector’s lifespan. The locking mechanism keeps the connector securely in place, even when exposed to vibration or movement. The connector also resists twisting, which helps maintain a stable connection over time.

Tip: The combination of shielding and durable materials makes this connector a reliable choice for industrial and high-performance applications.

Mounting and Installation

The 10126-3000PE uses a free-hanging mounting style, which means users can install it without needing a fixed panel or enclosure. This flexibility allows for quick and easy installation in tight or awkward spaces. The quick-release latch simplifies both installation and removal, saving time during maintenance or upgrades. The connector’s design supports use in challenging environments, such as factories or outdoor telecom equipment, where reliability and ease of access are critical.

-

Free-hanging mounting style for flexible placement

-

Quick-release latch for fast installation and removal

-

Suitable for use in harsh or space-constrained environments

These features help users achieve secure and efficient connections, even in demanding conditions.

Applications

Industrial Automation

Factories and production lines often use the 10126-3000PE connector in programmable logic controllers (PLCs) and sensor networks. These systems need reliable data and signal transmission in tight spaces. The connector fits well in control cabinets and on crowded circuit boards. Its secure locking mechanism prevents accidental disconnection during machine operation.

Telecom

Telecommunications equipment, such as base stations and signal routing boards, relies on high-density connectors. The 10126-3000PE supports fast and stable connections between devices. Engineers choose this connector for its ability to handle multiple signals in a small footprint. This helps telecom companies save space in racks and enclosures.

Medical Devices

Medical diagnostic machines and monitoring systems require precise and stable connections. The 10126-3000PE provides consistent performance in these sensitive environments. Its shielding protects against electromagnetic interference, which is important for accurate readings. Hospitals and labs benefit from the connector’s durability and easy installation.

Embedded Systems

Single-board computers and high-density I/O expansion modules often use this connector. Designers select the 10126-3000PE when they need to connect many signals in a compact device. The connector’s small size and reliable contacts make it ideal for embedded systems where space is limited.

Test Equipment

Oscilloscopes, signal analyzers, and data loggers depend on secure and repeatable connections. The 10126-3000PE ensures accurate data transfer during testing and measurement. Its robust construction withstands frequent plugging and unplugging, which is common in laboratory settings.

Note: The 10126-3000PE excels in space-constrained and high-density environments. Its design supports a wide range of applications across different industries.

Why Choose 10126-3000PE?

Advantages

The 10126-3000PE connector offers several clear advantages over similar products. Engineers value its strong reliability. The connector uses gold-plated contacts, which help maintain a stable connection and prevent corrosion. Its metal shell provides excellent shielding against electromagnetic interference. This feature protects signals from noise in busy electronic environments.

The connector also stands out for its ease of use. The quick-release latch allows for fast installation and removal. Users do not need special tools to connect or disconnect it. The free-hanging mounting style gives flexibility during setup. This design works well in tight spaces where other connectors might not fit.

A table below summarizes the main benefits:

|

Advantage |

Description |

|---|---|

|

Reliability |

Gold-plated contacts, secure locking mechanism |

|

Shielding |

Metal shell reduces electromagnetic interference |

|

Ease of Use |

Quick-release latch, tool-free installation |

|

Versatility |

Works in many industries and environments |

Tip: The connector’s durability and shielding make it a top choice for demanding applications.

User Scenarios

Many users select the 10126-3000PE for projects that require dependable connections in small spaces. For example, a factory automation engineer might use it to link sensors to a programmable logic controller. The connector’s secure latch keeps connections stable, even when machines vibrate.

A telecom technician may install this connector in a base station. The compact size helps save space in crowded equipment racks. Medical device designers often choose it for diagnostic machines. The strong shielding ensures accurate data transfer, which is important for patient safety.

In test labs, engineers use the connector with oscilloscopes and data loggers. The connector’s durability allows for frequent plugging and unplugging. Embedded system developers also rely on it for high-density I/O expansion, where space and reliability matter most.

The connector delivers reliable performance in many demanding environments. Its gold contacts, secure locking, and compact size support high-density designs. The table below highlights key technical strengths:

|

Parameter |

Value |

Explanation/Significance |

|---|---|---|

|

Number of Positions |

Pin count for compatibility |

|

|

Operating Temperature |

-55°C to 105°C |

Reliable in harsh conditions |

|

Pitch |

2.54 mm |

Critical for layout and fit |

|

Current Rating |

1A |

Safe current capacity |

|

Contact Finish |

Gold |

Corrosion resistance |

Engineers in automation, telecom, and medical fields benefit from its robust design. This connector fits projects where space, reliability, and signal quality matter most.

FAQ

What cable types work with the 10126-3000PE connector?

The 10126-3000PE supports discrete wires from AWG24 to AWG30. It does not fit flat cables. Users often choose 3M pleated foil cables for controlled impedance and reliable performance.

Can users install the 10126-3000PE without special tools?

Yes. The connector features a quick-release latch and solder cup termination. Most users can install or remove it using standard hand tools. No special equipment is required.

Is the 10126-3000PE suitable for harsh environments?

Engineers designed the 10126-3000PE with a metal shell and high-temperature plastic. It resists vibration, twisting, and electromagnetic interference. This makes it ideal for industrial and outdoor settings.

How many mating cycles can the connector handle?

The 10126-3000PE endures up to 500 mating cycles. Gold-plated contacts help maintain signal quality and reduce wear over repeated use.

What devices commonly use the 10126-3000PE?

Typical devices include PLCs, base stations, diagnostic machines, single-board computers, and oscilloscopes. The connector fits applications that need high-density, reliable connections in small spaces.

See Also

Unveiling The Main Automotive Features Of FREESCALE MCF5251CVM140

A Detailed Look At MC9S12DJ256MFUE Specs For Vehicles

Highlighting The Best Three Features Of SPC5605BMLL6 And SPC5607BMLL6 ECUs

An In-Depth Review Of MC9S12XEQ512CAL Key Specifications

Steps To Integrate AEAT-8800-Q24 For Improved Robotics Efficiency