Microcontrollers are crucial for modern technology. Their demand increases steadily, driving innovation across industries. However, Global Supply Chains, Microcontroller availability faces significant volatility and complexity. This impacts both supply and pricing. Businesses must identify and partner with reliable microcontroller exporters for sustained operations. For instance, the Philippines Microcontroller market, like others, experiences these challenges. Securing dependable suppliers within the Global Supply Chains, Microcontroller landscape is essential for business continuity and product quality.

Key Takeaways

Microcontrollers are important for modern technology. Their supply chain is complex and can change quickly.

Businesses must find reliable exporters. This helps them keep making products and ensures good quality.

Good exporters have strong finances and good quality control. They also talk openly and offer technical help.

Companies should check exporters carefully. They can visit factories and ask for references.

Building strong supply chains means talking with suppliers. It also means using many suppliers and new technology.

Current Microcontroller Supply Chain Landscape

Global Demand and Shortage Impacts

The semiconductor shortage significantly affects various industries. The automotive and electronics sectors face particular challenges. Automakers have experienced substantial production cuts. For example, Nissan and Honda reduced their production plans due to the global chip shortage. This shortage stems from increased demand for electronics and an unexpected recovery in car sales after the COVID-19 pandemic.

Seiji Sugiura, a senior analyst at Tokai Tokyo Research Institute, stated that it would likely take over a month for normal supply to resume, leading to very unstable production for Toyota in April and May. He also anticipated similar difficulties for Honda, Nissan, and other manufacturers.

Akira Minamikawa, an analyst at Omdia, commented that a full recovery could span three months to half a year. He emphasized the significant impact due to already low chip stockpiles.

Renesas holds approximately 30% of the global market share for microcontroller unit chips used in automobiles. This indicates the shortage’s effects extend to car manufacturers beyond Japan, including those in Europe and the United States.

Geopolitical Factors and Key Hubs

Geopolitical factors play a crucial role in the current landscape. Regions like Taiwan are critical hubs for microcontroller production. Their advanced manufacturing capabilities are central to the Global Supply Chains, Microcontroller ecosystem. Trade policies, international relations, and regional stability directly influence the flow and availability of these essential components. Any disruptions in these key areas can have widespread effects on global supply.

Lead Times and Cost Volatility

The current environment also features extended lead times and volatile costs. Logistics delays contribute to these longer waiting periods for components. The increasing costs of raw materials, energy, and shipping further drive up prices across the board. Businesses must navigate these fluctuating conditions to secure necessary components and manage their budgets effectively. This volatility makes long-term planning challenging for many companies.

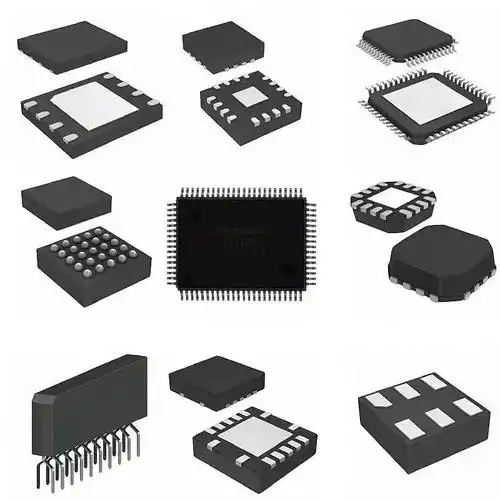

Key Criteria for Reliable Microcontroller Exporters

Businesses need clear criteria to select partners. Established IC global distributors often meet these criteria. They offer broader access and reliability within the Global Supply Chains, Microcontroller ecosystem. These distributors provide a crucial link between manufacturers and end-users.

Financial Stability and Capacity

Exporters must demonstrate strong financial health. This ensures they can invest in technology and maintain operations. A financially stable exporter provides security. They can weather economic downturns without disrupting supply. They also need sufficient production capacity. This allows them to meet demand, even for large orders. Established IC global distributors often have robust financial backing. They also manage extensive inventories. This helps them fulfill diverse customer needs consistently.

Quality Control and Certifications

Quality is paramount for microcontrollers. Exporters must implement strict quality control processes. They should adhere to international standards. Certifications like ISO 9001 demonstrate a commitment to quality. These certifications assure buyers of consistent product quality. They also show adherence to manufacturing best practices. Reliable exporters perform rigorous testing. They ensure components meet specifications and performance requirements. This minimizes defects and ensures product reliability.

Transparency and Communication

Open communication builds trust. Exporters should provide clear information about their products and processes. They must share updates on lead times and potential delays. This helps buyers plan effectively. Transparency in pricing and terms prevents misunderstandings. It fosters a strong, long-term partnership. Good communication means quick responses to inquiries. It also involves proactive sharing of relevant data. This ensures both parties stay informed.

Technical Support and After-Sales

Microcontrollers are complex components. Buyers often need technical assistance. Reliable exporters offer expert technical support. They help with integration and troubleshooting. After-sales service is also crucial. This includes warranty support and handling returns efficiently. Strong technical backing ensures smooth product development. It minimizes downtime for the buyer. This comprehensive support adds significant value to the partnership.

Vetting Potential Exporters

Businesses must carefully evaluate potential microcontroller exporters. This process ensures they partner with reliable and capable suppliers. Thorough vetting minimizes risks and secures a consistent supply of quality components.

Due Diligence and Background Checks

Companies conduct thorough due diligence on potential exporters. This process involves checking their legal standing and financial health. Businesses verify the exporter’s registration and licensing. They also examine their operational history. Understanding an exporter’s past performance helps predict future reliability. Financial records reveal stability and capacity for investment. A strong financial background indicates a lower risk of business failure. This initial investigation provides a foundational understanding of the exporter’s credibility.

Supplier Audits and Site Visits

Performing supplier audits offers deeper insights into an exporter’s operations. Auditors verify manufacturing processes and quality control systems. They ensure the exporter follows industry standards and best practices. Site visits allow buyers to see facilities firsthand. They can assess production lines, equipment, and cleanliness. Meeting key personnel during a visit helps build rapport and trust. These direct observations confirm the exporter’s capabilities and commitment to quality. They also help identify any potential red flags not visible in documentation.

Industry Reputation and References

An exporter’s industry reputation provides valuable information. Businesses research trade publications and industry forums. They look for news articles or reports about the exporter. Requesting references from other clients is also crucial. Contacting these references offers insights into the exporter’s reliability, communication, and product quality. Positive feedback from existing partners strengthens confidence in a potential supplier. Conversely, negative reports or a lack of verifiable references signal caution. A strong reputation often reflects consistent performance and ethical business practices.

Pilot Orders and Performance

Placing pilot orders serves as a practical test for new exporters. A pilot order is a small, initial purchase. It allows businesses to evaluate the exporter’s ability to deliver on promises. During this phase, companies assess several key performance indicators.

They evaluate:

Performance Metrics: This includes processing speed, power consumption, memory utilization, and real-time responsiveness.

Reliability and Stability: Businesses assess error rates, uptime, and mean time between failures (MTBF).

Cost-Effectiveness: They analyze the bill of materials (BOM) cost, manufacturing cost, and total cost of ownership (TCO).

Development Efficiency: Companies track development time, bug resolution rate, and code quality.

Security: They evaluate vulnerability assessment, encryption strength, and secure boot implementation.

Scalability and Flexibility: Businesses assess ease of integration, compatibility with other systems, and adaptability to future requirements.

User Experience (UX): They measure responsiveness, ease of use, and overall user satisfaction.

These evaluations provide concrete data on the exporter’s product quality and service. Successful pilot orders build confidence for larger, long-term partnerships.

Building Resilient Global Supply Chains

Businesses must build strong supply chains. This ensures a steady flow of microcontrollers. Resilient supply chains can withstand disruptions and maintain operations.

Communication and Collaboration

Effective communication forms the backbone of a resilient supply chain. Companies actively share information with their suppliers. They discuss forecasts, potential issues, and market changes. Regular meetings and feedback sessions strengthen these relationships. Collaborative planning helps both parties anticipate challenges. It allows them to develop solutions together. This open dialogue fosters trust and mutual understanding.

Contract Negotiation and Terms

Careful contract negotiation protects buyers. Comprehensive agreements define expectations and responsibilities. They safeguard against unforeseen problems. Essential contractual terms include:

Product Specifications and Quality Standards: These clearly define the technical details and performance benchmarks for microcontrollers.

Delivery and Acceptance Terms: They specify shipping methods, schedules, and inspection procedures.

Pricing and Payment Terms: These detail the cost structure and payment timelines.

Warranties and Guarantees: They include provisions for product warranties and remedies for defects.

Intellectual Property Rights: These address ownership and licensing.

Confidentiality and Non-Disclosure: These protect sensitive information.

Indemnification: This outlines responsibilities for liabilities.

Limitation of Liability: This defines the extent of each party’s liability.

Termination Clauses: These specify conditions for ending the agreement.

Dispute Resolution: These establish mechanisms for resolving conflicts.

Governing Law: This determines the legal jurisdiction for the agreement.

Supplier Diversification Strategies

Relying on a single supplier creates significant risk. Businesses implement diversification strategies. They work with multiple suppliers for critical components. This reduces vulnerability to disruptions from one source. If one supplier faces issues, others can fill the gap. This strategy enhances the overall resilience of Global Supply Chains, Microcontroller procurement.

Technology for Supply Chain Visibility

Modern technology offers powerful tools for supply chain management. Companies use advanced software for real-time tracking. IoT sensors monitor shipments and inventory levels. Artificial intelligence analyzes data to predict potential delays. Blockchain technology provides secure and transparent transaction records. These tools offer end-to-end visibility. They allow businesses to make informed decisions quickly. This proactive approach helps mitigate risks effectively.

Mitigating Procurement Risks for Microcontrollers

Businesses must actively manage risks in microcontroller procurement. This ensures a stable supply and protects operations. They develop robust strategies to enhance supply chain resilience.

Inventory Management and Contingency

Effective inventory management prevents shortages. Companies maintain optimal stock levels. They balance holding costs with supply security. Businesses also create contingency plans. These plans address unexpected disruptions. For example, they identify alternative shipping routes or backup suppliers. This proactive approach minimizes the impact of unforeseen events. It ensures continuous production.

Counterfeit Component Prevention

Counterfeit microcontrollers pose a significant threat. They can compromise product quality and safety. Companies implement strict verification processes. They source components from authorized distributors. They also use advanced authentication technologies. These measures help detect and prevent counterfeit parts from entering the supply chain. Due diligence protects product integrity and brand reputation.

Regulatory Compliance and Security

Adhering to regulations is crucial. Businesses comply with international trade laws and export controls. They also prioritize supply chain security. This involves protecting components from theft or tampering. Secure logistics and warehousing are essential. Government subsidies often influence exporter expansion. These subsidies can encourage compliance and secure practices. They help exporters invest in better security measures. This strengthens the overall Global Supply Chains, Microcontroller ecosystem.

Sustainability and Ethical Sourcing

Sustainability and ethical practices are increasingly important. Companies choose exporters committed to environmental protection. They also ensure fair labor practices. This includes avoiding child labor and unsafe working conditions. Ethical sourcing builds a responsible supply chain. It enhances brand image and meets consumer expectations. Businesses contribute to a better global community.

Reliable microcontroller exporters are critical for sustained innovation and operational stability. Businesses must identify, vet, and manage these crucial partnerships effectively. Proactive planning, thorough due diligence, and strong relationships form the foundation for navigating complex global supply chains. Companies must continuously adapt and build resilience in an ever-evolving market.

Securing dependable suppliers ensures business continuity and product quality.

FAQ

What causes microcontroller shortages?

Global demand for electronics often increases rapidly. Geopolitical factors and production disruptions also play a role. For example, factory fires or natural disasters can halt production. These events create imbalances between supply and demand. This leads to widespread shortages.

How do businesses find reliable microcontroller exporters?

Businesses conduct thorough due diligence. They check financial stability and quality certifications. They also perform supplier audits and site visits. Industry reputation and references provide valuable insights. Pilot orders help evaluate performance before large commitments.

Why is supply chain diversification important for microcontrollers?

Relying on a single supplier creates significant risk. Diversification spreads risk across multiple sources. If one supplier faces issues, others can maintain supply. This strategy enhances resilience against disruptions. It ensures business continuity.

What are the risks of counterfeit microcontrollers?

Counterfeit microcontrollers can compromise product quality. They may lead to system failures or safety hazards. Using fake components damages a company’s reputation. It also creates legal liabilities. Strict verification processes are essential to prevent these risks.

See Also

MC9S12XET512VAG Microcontroller: Integrating Automotive Electronics with Strategic Practice

SPC56 Microcontrollers: Mastering Automotive Powertrains Through Core Engine Application

Electronic Components: Analyzing Innovation, Quality, and Future Trends for Excellence

XCF01SVOG20C: Three Key Transformations for Industrial Automation Success

MC9S12XEQ512CAL: Deep-Dive Applications in Automotive Electronics and Industrial Control