Choosing between the TMC2209 and TMC2130 can make a big difference in stepper motor control. The TMC2209 offers ultra-silent operation, while the TMC2130 provides advanced tuning features. Engineers often compare these drivers because picking the right one impacts torque, speed, and reliability. The table below shows how technical factors like microstepping and torque margin affect performance and guide the selection of ADI Trinamic ICs from an ADI Trinamic distributor.

|

Parameter |

Typical Value or Rule |

Impact on Driver Choice |

|---|---|---|

|

Microstep Resolution |

Up to 50,000 steps/rev |

Higher resolution, lower torque per step |

|

Torque Margin |

≥ 50% above load requirement |

Ensures reliable, smooth operation |

|

Inertia Ratio |

≤ 10:1 (system:rotor) |

Better acceleration and deceleration |

Key Takeaways

-

The TMC2209 driver offers ultra-quiet operation with easy setup, making it perfect for 3D printers and consumer devices where noise matters.

-

The TMC2130 provides advanced tuning and diagnostics through its SPI interface, ideal for industrial automation and robotics requiring precise control.

-

Both drivers support up to 256 microsteps for smooth and accurate motor movement, improving print quality and machine performance.

-

Built-in protection features like stall detection and over-temperature safeguards help ensure reliable and safe motor operation.

-

For higher power needs, the tmc5160 driver offers more current and advanced features, serving as a strong upgrade option for demanding applications.

Overview

TMC2209

The TMC2209 stands out as a popular stepper motor driver IC for both hobbyists and professionals. This driver offers a blend of high performance and quiet operation, making it a top choice for 3D printers and other precision devices. The TMC2209 uses StealthChop2 technology, which ensures silent movement even at low speeds. Engineers often select this motor driver IC for its energy efficiency and advanced control features.

Below is a summary of the main features and technical specifications:

|

Metric / Feature |

Specification / Description |

|---|---|

|

Maximum Current Output |

Up to 2.0A continuous, 2.8A peak |

|

Voltage Range |

4.75V to 29V DC |

|

Micro-stepping Resolution |

1 to 256 steps with MicroPlyer interpolation |

|

RDS(on) Values |

170mΩ typical at 25°C (Low Heat-Up for LS & HS) |

|

Silent Operation |

StealthChop2 technology for quiet motor control |

|

Motor Control |

SpreadCycle dynamic motor control chopper |

|

Stall Detection |

StallGuard4 load and stall detection |

|

Energy Saving |

CoolStep current control enabling up to 75% energy savings |

|

Interface |

UART interface for configuration and diagnostics |

|

Sense Resistor |

Internal sense resistor option |

|

Power Management |

Low power standby modes |

|

Additional Features |

Passive braking, freewheeling, automatic power down |

|

Package |

Compact QFN package with large heat slug |

The TMC2209 supports up to 256 microsteps per full step, which allows for smooth and precise stepper motor movement. Its UART interface makes configuration and diagnostics simple. Many users appreciate the built-in sense resistor, which reduces board complexity.

TMC2130

The TMC2130 also ranks as a leading stepper motor driver IC, especially in applications that require advanced tuning and diagnostics. This driver supports both SPI and step/dir interfaces, giving engineers flexibility in system design. The TMC2130 evaluation board helps users test and optimize performance for their specific stepper motor applications.

-

The TMC2130 datasheet provides detailed technical specifications and electrical characteristics.

-

The TMC2130-EVAL board allows engineers to evaluate features and performance in real-world scenarios.

-

Suppliers follow strict quality standards, including ISO 9001 and ISO 13485 certifications, to ensure reliable and authentic components.

-

Each motor driver IC undergoes functional testing, visual inspection, and electrical validation before reaching customers.

The TMC2130 offers advanced features such as passive braking and a microstep table, which help improve stepper motor control in demanding environments. Many 3D printer brands and CNC machines use this driver for its reliability and flexibility.

adi trinamic ics

Technology

The adi trinamic ics family brings advanced motor control to many industries. These integrated circuits use unique technologies to improve stepper motor performance. StealthChop2 technology stands out for its ability to make motors run quietly. SpreadCycle provides smooth and precise current control. DCStep helps motors adjust speed and torque automatically. These features support the integration of stepper drivers into different systems.

Engineers often choose adi trinamic ics for their reliable integration with 3D printers, CNC machines, and smart devices. The chips allow for easy setup and tuning. Many users appreciate the low noise and high efficiency. The integration of these technologies helps devices run longer and quieter.

Note: The combination of StealthChop2, SpreadCycle, and DCStep gives designers more control over motor behavior. This integration leads to better results in both consumer and industrial products.

Product Family

The adi trinamic ics product family includes several popular stepper motor drivers. The TMC2209 and TMC2130 serve as reliable choices for many applications. The tmc5160 offers higher power and advanced features for demanding tasks. Each chip supports different levels of integration, making it easier for engineers to match the right driver to their needs.

|

Model |

Key Features |

Typical Applications |

|---|---|---|

|

TMC2209 |

Silent operation, UART interface |

3D printers, smart home |

|

TMC2130 |

SPI interface, microstep table |

CNC, robotics |

|

tmc5160 |

High power, DCStep, advanced control |

Industrial automation |

The adi trinamic ics family finds use in 3D printers, CNC machines, medical devices, and smart home products. Their integration into these systems improves motion control and reduces noise. Many brands trust these chips for their proven performance and easy integration.

Features

Current & Voltage

The TMC2209 and TMC2130 both deliver strong current and voltage capabilities for stepper motor control. The TMC2209 supports up to 2.0A RMS continuous current and 2.8A peak current. Its voltage range spans from 4.75V to 29V. This wide range allows the driver to work with many stepper motors in different applications. The TMC2130 offers similar current ratings, with up to 2.0A RMS and 2.5A peak, and a voltage range from 4.75V to 46V. This higher voltage ceiling gives the TMC2130 an edge in some industrial settings where higher voltages improve performance.

Both drivers use low RDS(on) MOSFETs, which help reduce heat and increase efficiency. The TMC2209 stands out for its energy efficiency, making it a good choice for projects that need maximum efficiency and low power consumption. These features ensure reliable operation and help maintain smooth motion control.

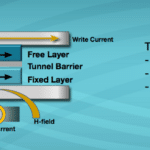

Interfaces

The TMC2209 and TMC2130 offer different communication interfaces for control and configuration. The TMC2209 uses a UART interface, which allows simple wiring and easy setup. Many users prefer UART for its straightforward integration with microcontrollers. The TMC2130 features an SPI interface, which provides more advanced features and precise control. SPI enables engineers to access detailed diagnostics and fine-tune stepper performance.

Both drivers support step/dir inputs, making them compatible with most motion control systems. The choice between UART and SPI depends on the level of control and the complexity of the application. For example, the TMC2130’s SPI interface allows for highly sophisticated motor control, while the TMC2209’s UART interface focuses on ease of use and quick integration.

Noise & StealthChop

Noise reduction is a key feature in both the TMC2209 and TMC2130. The TMC2209 uses StealthChop2 technology, which makes it an ultra-quiet motor driver. This feature is important for 3D printers, medical devices, and smart home products where silent operation matters. The TMC2130 also uses StealthChop, but the TMC2209’s updated version delivers even quieter performance.

SpreadCycle technology in both drivers ensures smooth motion control at higher speeds. The TMC2209’s focus on ultra-silent operation makes it ideal for environments where noise can be a problem. The TMC2130, with its passive braking feature, helps maintain control during sudden stops, adding another layer of safety and performance.

Tip: For applications that require the lowest possible noise, the TMC2209 offers the best solution among stepper drivers in its class.

Microstepping

Microstepping is a critical feature for achieving smooth and precise stepper motion. The TMC2209 supports up to 256 microsteps per full step, using MicroPlyer interpolation to create smooth motion even at low speeds. This feature improves print quality in 3D printers and enhances the motion control capabilities of other devices.

The TMC2130 also supports 256 microsteps and includes a microstep table for advanced tuning. This table allows engineers to adjust the stepper’s behavior for specific tasks, improving performance and flexibility. Both drivers deliver excellent microstepping, but the TMC2130’s advanced features give users more options for custom control.

Protection

Protection features help keep stepper drivers safe and reliable. The TMC2209 includes over-temperature, short-circuit, and under-voltage protection. These features prevent damage and extend the life of the driver. The TMC2130 offers similar protection, with added diagnostics through its SPI interface. Engineers can monitor the driver’s status and respond quickly to any issues.

Both drivers use built-in stall detection, which helps prevent missed steps and improves overall performance. The TMC2209’s StallGuard4 and the TMC2130’s StallGuard2 provide accurate feedback for stepper motor control. These features support energy efficiency and help maintain smooth operation in demanding environments.

Note: The combination of advanced features and robust protection makes both the TMC2209 and TMC2130 reliable choices for stepper motor control in a wide range of applications.

Applications

3D Printers & CNC

Many 3D printing and CNC projects rely on stepper drivers for smooth and reliable motion. The TMC2130 and TMC2209 both play important roles in these systems. Users have tested TMC2130 drivers on CNC shields and 3D printers like the HEVO. They found that motors ran more quietly than with older drivers. The StallGuard feature replaced mechanical end-stop switches, making the setup simpler. Some users noted torque changes and real-world challenges, such as loose connections, but the overall performance improved.

The TMC2209 brings silent operation to 3D printers using StealthChop technology. It reduces noise and heat, which helps printers run cooler. This driver supports operation without end-stop switches and uses UART for easy configuration. Many brands, including Prusa and Creality, use these drivers to achieve high-quality prints and precise positioning. These features make both drivers popular for stepper motor applications in 3D printing and CNC.

Low noise and precise control matter in 3D printing because they improve print quality and reduce distractions in workspaces.

Industrial Automation

Industrial automation systems demand high-performance applications and reliable stepper control. The TMC2130 supports two-phase stepper motors up to 2A continuous and 2.5A peak. It operates from 4.75V to 46V and uses STEP/DIR and SPI interfaces. The table below shows key specifications:

|

Specification |

Details |

|---|---|

|

Motor Drive Capability |

Up to 2A continuous, 2.5A peak |

|

Supply Voltage Range |

4.75V to 46V |

|

Interfaces |

STEP/DIR, SPI |

|

Special Features |

StealthChop, SpreadCycle, StallGuard2 |

In factory and laboratory automation, the TMC2130 enables accurate layering and calibration. Its features, such as StealthChop and StallGuard2, help maintain smooth and quiet operation. These qualities are essential for automated manufacturing, where precise positioning and consistent performance are critical.

Medical & Consumer

Medical devices and consumer products benefit from stepper drivers that offer quiet and efficient operation. The TMC2130 is used in pumps and valves, providing reliable and precise control. This improves patient safety and device reliability. Rigorous testing ensures that these drivers meet the high standards required in healthcare.

In smart home devices, such as automated blinds and camera gimbals, stepper drivers like the TMC2209 reduce noise and improve battery life. These features make them ideal for consumer products that require silent and efficient motion. The combination of low noise, energy efficiency, and advanced control supports a wide range of stepper motor applications in both medical and consumer markets.

tmc5160 and Advanced Options

High Power

The tmc5160 stands out as a high-power solution in the Trinamic product family. This advanced stepper motor driver supports up to 3A RMS continuous current and operates with supply voltages from 8V to 60V. Engineers often select the tmc5160 for applications that require more torque and speed than the TMC2209 or TMC2130 can provide. The tmc5160 features DCStep technology, which allows motors to adjust speed and torque automatically. This function helps maintain motion even when the load changes. The tmc5160 also includes StealthChop2 and SpreadCycle, which ensure smooth and quiet operation at both low and high speeds.

Many industrial machines, robotics, and automated systems use the tmc5160 for its high-performance capabilities. The driver’s advanced interfaces, such as SPI and step/dir, give engineers flexibility in system design. The tmc5160 improves efficiency by reducing heat and power loss, which supports longer machine life and better reliability.

Note: The tmc5160 offers energy efficiency and robust protection features, making it ideal for demanding environments.

Upgrade Paths

Engineers looking to upgrade from the TMC2209 or TMC2130 often choose the tmc5160 for more power and advanced control. The tmc5160 works well in industrial automation, CNC machines, and robotics where higher current and voltage are needed. For even more specialized industrial scenarios, the TMC2240 provides additional features and diagnostics.

To evaluate the tmc5160, users can purchase evaluation boards and modules from authorized distributors. These tools help engineers test the driver’s performance before integrating it into their systems. Many online electronics retailers and official ADI Trinamic distributors offer the tmc5160 and related evaluation kits.

Tip: When selecting an advanced stepper motor driver, consider the tmc5160 for its balance of power, efficiency, and advanced features.

Selection

The TMC2209 delivers ultra-quiet performance and simple setup, making it ideal for hobbyists and consumer devices. The TMC2130 offers advanced tuning and diagnostics, which suits industrial and robotics projects. Users should match their choice to their needs—quiet operation for home use, advanced features for demanding environments.

For more details or to purchase, visit authorized ADI Trinamic distributors or check official datasheets for each driver.

What makes the TMC2209 ideal for 3D printers?

The TMC2209 uses StealthChop2 technology for ultra-quiet operation. This feature helps 3D printers run smoothly and silently. Many users choose it for home and office environments where noise reduction matters.

Can the TMC2130 and TMC2209 replace each other?

Both drivers support similar stepper motors. The TMC2130 offers SPI for advanced control, while the TMC2209 uses UART for easy setup. Users should check their system’s interface requirements before swapping drivers.

How does StallGuard help in motor control?

StallGuard detects motor stalls without extra sensors. It provides feedback for precise positioning and protects against missed steps. This feature improves reliability in 3D printers, CNC machines, and robotics.

Which driver works best for industrial automation?

The TMC2130 suits industrial automation with its higher voltage range and SPI interface. It allows advanced tuning and diagnostics. Many engineers select it for factory equipment and robotics.

Where can users find evaluation boards for these drivers?

Users can purchase evaluation boards from authorized ADI Trinamic distributors. These boards help test features and performance before full system integration.

See Also

IRF820 N-Channel MOSFET For Power And Motor Control

Enhancing Automotive Performance Using NXP MC9S12 Microcontrollers

SPC56 Microcontrollers Simplify Engine Control Applications Effectively

Three Best Methods To Integrate MC9S12XET512VAG Microcontroller

Using STM32F103C8T6 MCUs For Bluetooth Robot Control