The ADUM6400CRWZ brings advanced isolation technology to communication systems facing high-voltage challenges. It uses magnetic coupling to separate sensitive circuits and delivers up to 5 kV rms isolation voltage. Engineers benefit from its robust safety certifications and integrated isoPower® DC-to-DC converter, which supplies up to 400 mW of isolated power. The device’s 25 Mbps data rate and high common-mode transient immunity ensure reliable data transfer even in harsh environments. Designers find that its wide temperature range and compact packaging simplify integration while maintaining strong protection.

Key Takeaways

-

The ADUM6400CRWZ provides strong electrical isolation up to 5,000 Vrms, protecting sensitive circuits from high voltages and noise.

-

It supports fast data transfer speeds up to 25 Mbps, ensuring reliable communication even in harsh and noisy environments.

-

Integrated IsoPower technology supplies isolated power, reducing the need for extra power supplies and simplifying system design.

-

The device works well in tough conditions with a wide temperature range and meets strict safety certifications for industrial and medical use.

-

Its compact design and multiple channels help engineers build smaller, safer, and more efficient communication systems quickly.

Isolation Challenges

Data Integrity Risks

Data integrity stands as a major concern in high-voltage communication systems. Engineers often face problems like ground loops and noise interference, which can corrupt signals and cause system errors. These issues become more severe in environments with strong electromagnetic interference or rapid voltage changes.

-

Ground loops can introduce unwanted currents, leading to false data or communication failures.

-

Noise from nearby equipment or power lines can disrupt digital signals, making it hard to maintain reliable communication.

-

Electrostatic discharge (ESD) can damage sensitive components, causing data loss or permanent failure.

-

Accurate measurement of voltage, current, and temperature becomes difficult under harsh conditions, which affects system performance.

Designers must also consider the increasing complexity of modern power systems. As systems grow more advanced, they require higher reliability, longer service life, and better signal integrity. These demands push the limits of traditional isolation technologies.

Safety Concerns

High-voltage systems present serious safety risks for both people and equipment. Even voltages above 60 V can be dangerous, especially in wet or industrial environments.

Note: OSHA and NIOSH data show that arc flash incidents have caused hundreds of injuries and fatalities over the past decades, even at lower DC voltages.

To address these risks, engineers use several safety practices:

-

Minimum spacing and creepage distance between high-voltage points and ground

-

Solid grounding connections to handle fault currents

-

Protective equipment like eye and face shields during testing

-

Safety interlocks that cut power if covers or connections are opened

-

Redundant safety systems and emergency shutoffs

A table below summarizes common safety practices:

|

Safety Practice |

Description |

|---|---|

|

Minimum Spacing |

1 inch per 7,500 V between high voltage and ground |

|

Creepage Distance |

1 inch per 7,500 V for insulators |

|

Grounding |

Solid, high-capacity ground connections |

|

Protective Equipment |

Eye and face protection during high-power tests |

|

Safety Interlocks |

Disable high voltage when opened |

|

Qualified Personnel |

Only trained staff supervise high-voltage tests |

Traditional Methods

Traditional isolation methods include optocouplers, capacitive isolators, and magnetic isolators. Each method has its own strengths and weaknesses.

-

Optocouplers use light to transfer signals but can suffer from optical aging and limited speed.

-

Capacitive isolators offer low delay and cost but need separate bias supplies.

-

Magnetic isolators work well for high-frequency applications but can be expensive.

Some common measurement techniques also have limitations:

|

Method |

Limitation |

Explanation |

|---|---|---|

|

Balanced Bridge |

Low accuracy with dual faults |

Cannot detect both positive and negative insulation faults at once |

|

Unbalanced Bridge |

Sensitive to Y capacitance |

Capacitance can distort measurements unless compensated |

|

High-Precision Voltmeter |

Not suitable for real-time monitoring |

Only used during manufacturing, not for continuous operation |

Traditional methods must maintain very high insulation resistance to prevent hazardous leakage currents. This makes it hard to detect insulation degradation before safety is compromised. As high-voltage systems become more complex, these limitations highlight the need for advanced isolation solutions.

ADUM6400CRWZ Solutions

Isolation Technology

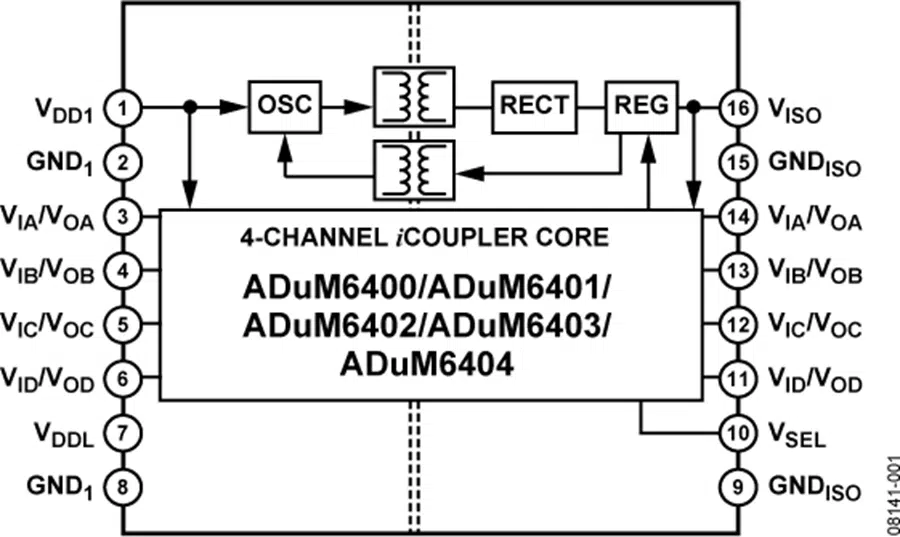

The ADUM6400CRWZ uses magnetic coupling to achieve galvanic isolation. This method separates the input and output sides of a circuit without any direct electrical connection. Engineers rely on this technology to protect sensitive components from high voltages and electrical surges. Magnetic coupling blocks dangerous currents while allowing fast digital signals to pass through. This approach also reduces the risk of ground loops, which can cause data errors and equipment damage.

The device’s isolation barrier withstands up to 5000 Vrms. This high rating ensures that the system remains safe even during severe voltage spikes. The ADUM6400CRWZ maintains signal integrity in environments with strong electromagnetic interference. Its robust design helps engineers meet strict safety standards in industrial and medical systems.

Note: Galvanic isolation using magnetic coupling offers a reliable solution for high-voltage applications. It keeps data flowing smoothly while protecting both people and equipment.

IsoPower® and iCoupler®

Analog Devices developed IsoPower® and iCoupler® technologies to improve isolation performance. The ADUM6400CRWZ combines these features to deliver both data and power across the isolation barrier. IsoPower® integrates a DC-to-DC converter that supplies up to 400 mW of regulated isolated power. This eliminates the need for a separate power supply on the isolated side, reducing board space and simplifying design.

iCoupler® technology enables high-speed digital communication. It supports data rates up to 25 Mbps, which is much faster than many traditional isolation methods. The combination of IsoPower® and iCoupler® allows the ADUM6400CRWZ to transmit data and power efficiently, even in noisy environments.

A comparison of isolation technologies highlights these advantages:

|

Technology |

Data Rate (Mbps) |

Isolation Voltage (kV) |

Integrated Power |

Typical Use Case |

|---|---|---|---|---|

|

Optocoupler |

1–5 |

2.5–5 |

No |

Basic signal isolation |

|

Capacitive |

10–20 |

2.5–5 |

No |

Low-power systems |

|

Magnetic (iCoupler®) |

25 |

5 |

Yes (IsoPower®) |

High-speed, robust |

The ADUM6400CRWZ stands out by combining high data rates, strong isolation, and integrated power delivery. This makes it ideal for complex communication systems that demand both safety and performance.

Performance Specs

The ADUM6400CRWZ offers a set of features that address the toughest isolation challenges. Its key specifications include:

-

5000 Vrms isolation voltage

-

Data rates up to 25 Mbps

-

Operating temperature range from -40°C to 105°C

-

Compact 16-SOIC package (7.50 mm width)

-

Four unidirectional digital channels

These features help engineers solve problems like noise, ground loops, and harsh operating conditions. The high common-mode transient immunity ensures that the device maintains reliable communication even when voltage levels change rapidly. The wide temperature range allows the ADUM6400CRWZ to perform in demanding industrial and medical environments.

A summary of the device’s performance appears in the table below:

|

Specification/Feature |

Value/Description |

|---|---|

|

Common-Mode Transient Immunity |

Greater than 25 kV/µs |

|

Integrated isoPower DC-to-DC |

Up to 400 mW regulated isolated power output |

|

Data Rate |

Up to 25 Mbps |

|

Operating Temperature |

Up to 105°C |

|

Safety and Regulatory Approvals |

UL, CSA, IEC 60601-1, IEC 60950-1, VDE |

These specifications show that the ADUM6400CRWZ maintains isolation integrity under high transient conditions. The integrated power output supports system designs that require both data and power isolation. Safety approvals confirm its suitability for critical applications.

Engineers choose the ADUM6400CRWZ for its ability to deliver fast, reliable, and safe digital communication in environments where traditional isolation methods may fall short.

Benefits

Design Simplicity

Engineers often look for solutions that make circuit design easier and faster. The ADUM6400CRWZ offers several features that support quick prototyping and streamlined layouts.

-

Convenient power connections use screw terminal blocks, which allow for secure and easy wiring.

-

An add-on BNC connector supports 50 Ω signal sources, making signal testing straightforward.

-

On-board signal routing helps reduce layout complexity and keeps signal paths short.

-

The device supports signal wrap back, which minimizes transmission line effects and improves signal quality.

-

Pull-up and pull-down resistors come pre-installed for control lines, saving time during setup.

-

IsoPower technology provides isolated power, removing the need for extra power supplies.

-

The project area accepts both surface-mount and through-hole devices, giving designers flexibility.

These features create a ready-to-use platform that simplifies connections and layout, making the ADUM6400CRWZ an excellent choice for both new designs and upgrades.

Reliability

Reliability remains a top priority in high-voltage communication systems. Analog Devices maintains strict quality and reliability checks throughout the design and manufacturing process. The company aims for zero defects in every product shipped. Qualification summaries and reliability data support the high standards set for the ADUM6400CRWZ.

The device also meets multiple safety and regulatory certifications, including UL, CSA, IEC 60601-1, IEC 60950-1, and VDE. These certifications confirm its suitability for critical applications where failure is not an option.

Efficiency

The ADUM6400CRWZ improves system efficiency through integrated features and strong performance metrics. The table below highlights key efficiency improvements:

|

Metric |

Value |

Explanation |

|---|---|---|

|

Isolated Power Output |

Integrated isoPower DC-to-DC converter reduces system size and complexity. |

|

|

Data Rate |

Up to 25 Mbps |

High data rate capability improves communication efficiency. |

|

Common-Mode Transient Immunity |

> 25 kV/μs |

Enhances signal integrity and robustness in noisy environments. |

|

PWM Frequency (DC-DC Converter) |

625 kHz |

High switching frequency contributes to efficient power conversion. |

|

Output Ripple |

50 mV p-p |

Low ripple ensures stable power delivery and reduces noise. |

|

Operating Temperature |

Up to 105°C |

Supports reliable operation in demanding environments, contributing to overall system efficiency. |

These metrics show that the device not only saves board space but also delivers stable power and fast data transfer. The ADUM6400CRWZ helps engineers build systems that run smoothly, even in harsh conditions.

Applications

Industrial Systems

Factories and power plants often use high-voltage equipment. Engineers need to protect control circuits from dangerous voltages. The ADUM6400CRWZ helps by providing strong isolation between control systems and high-power machinery. For example, in motor drives, the device separates the low-voltage controller from the high-voltage inverter. This setup prevents electrical surges from damaging sensitive electronics. The device’s high common-mode transient immunity keeps signals clear, even when large motors start or stop. Many industrial automation systems use this isolator to keep workers and equipment safe.

Tip: Using digital isolators in industrial systems reduces downtime and maintenance costs.

Medical Devices

Medical equipment must protect patients and staff from electrical hazards. Devices like patient monitors and infusion pumps use isolation to separate patient-connected circuits from the main power supply. The ADUM6400CRWZ meets strict medical safety standards. It provides reliable data transfer and power isolation in compact medical devices. For instance, in electrocardiogram (ECG) machines, the isolator ensures that signals from the patient reach the monitoring system without risk of shock. Hospitals trust this technology to maintain both safety and performance.

|

Medical Application |

Isolation Role |

Benefit |

|---|---|---|

|

ECG Machines |

Patient-to-system isolation |

Prevents electrical shock |

|

Infusion Pumps |

Power/data isolation |

Ensures safe operation |

|

Imaging Equipment |

Signal integrity |

Reduces noise in measurements |

Communication Equipment

Modern communication systems require fast and secure data transfer. Base stations, routers, and network switches often operate in environments with electrical noise. The ADUM6400CRWZ supports high-speed data rates and robust isolation. In wireless base stations, the device isolates digital control signals from high-voltage power supplies. This design keeps data transmission stable and prevents ground loops. Communication equipment manufacturers use this isolator to improve reliability and reduce signal errors.

Engineers select digital isolators to ensure safe, high-quality communication in demanding settings.

ADUM6400CRWZ vs. Traditional Isolation

Optocoupler Comparison

Optocouplers have served as a standard solution for electrical isolation in communication systems. They use light to transfer signals across an isolation barrier. This method provides strong protection against electrical and magnetic noise. However, optocouplers face several challenges. Their data transfer rates remain limited by the speed of LEDs. Over time, LED aging can reduce performance and reliability. Power consumption is often higher, and these devices may not handle high temperatures as well as newer technologies.

The ADUM6400CRWZ uses iCoupler inductive coupling instead of light. This approach supports much faster data rates, up to 25 Mbps, and offers high transient immunity. The chip-scale transformers inside the device resist external magnetic noise. Unlike optocouplers, the ADUM6400CRWZ does not suffer from LED wear, which improves long-term reliability.

|

Feature |

ADUM6400CRWZ (iCoupler) |

Optocoupler |

|---|---|---|

|

Isolation Technology |

Inductive coupling |

Optical coupling |

|

Data Rate |

Up to 25 Mbps |

1–5 Mbps |

|

Power Consumption |

Lower |

Higher |

|

Channel Integration |

Multiple per IC |

Often single channel |

|

Aging Effects |

None |

LED wear over time |

Integration

Modern systems demand compact designs and fewer components. The ADUM6400CRWZ integrates multiple isolated channels and an isoPower DC-to-DC converter in one package. This reduces board space and simplifies circuit layouts. Engineers can design smaller, more efficient systems with fewer external parts. Traditional isolation methods, such as optocouplers, often require separate power supplies and more devices to achieve the same level of functionality.

-

iCoupler technology allows for multiple channels in a single IC.

-

Integrated isolated power eliminates the need for extra power modules.

-

System size and complexity decrease, making assembly and maintenance easier.

Integration leads to faster development cycles and lower system costs.

Long-Term Value

Choosing the right isolation technology affects system performance and maintenance over time. The ADUM6400CRWZ provides high reliability because it avoids issues like LED aging. Its high transient immunity and wide temperature range ensure stable operation in harsh environments. Lower power consumption also means less heat and longer component life.

Many engineers select iCoupler-based isolators for high-speed data acquisition and industrial measurement systems. These devices deliver robust isolation, fast communication, and reduced total cost of ownership. The ADUM6400CRWZ stands out as a future-ready solution for demanding applications.

The ADUM6400CRWZ stands out as a reliable solution for high-voltage isolation in communication systems. Its robust features include a 5 kV rms isolation voltage, up to 25 Mbps data rate, and integrated isoPower DC-to-DC converter. The table below highlights its technical strengths:

|

Feature |

Specification |

|---|---|

|

Isolation Voltage |

5000 Vrms |

|

Data Rate |

Up to 25 Mbps |

|

Output Power |

Up to 400 mW |

|

Safety Certifications |

UL, CSA, IEC 60601-1, VDE |

Designers can trust this device for safe, efficient, and compact system designs. Evaluation boards and technical guides support real-world testing and integration.

What is the main advantage of using the ADUM6400CRWZ in communication systems?

The ADUM6400CRWZ provides strong isolation and fast data transfer. Engineers can protect sensitive circuits from high voltages and noise. This device also reduces design complexity by integrating power and data isolation in one compact package.

How does IsoPower® technology benefit system designers?

IsoPower® technology supplies up to 400 mW of isolated power. Designers do not need a separate power supply for the isolated side. This feature saves board space and simplifies the overall system layout.

Can the ADUM6400CRWZ operate in harsh environments?

Yes. The device works in temperatures from -40°C to 105°C. It resists electrical noise and voltage spikes. Many industrial and medical systems use it for reliable performance in demanding conditions.

What certifications does the ADUM6400CRWZ meet?

|

Certification |

Application Area |

|---|---|

|

UL, CSA |

General safety |

|

IEC 60601-1 |

Medical devices |

|

IEC 60950-1 |

Information technology |

|

VDE |

Industrial equipment |

These certifications show the device meets strict safety standards.

See Also

Enhancing Process Control Using The AD74413RBCPZ Device

How AD9736BBCZ Is Shaping Wireless Communication Advances

A Detailed Guide To Using AD620AN In TV Power Systems

Discover The Leading Three Features Of R5F64219JFB Audio

Reasons To Select Coilcraft XPL2010 For VRM And VRD