Traditional touchscreens often fail in tough modern conditions, particularly when it comes to Human-Machine Interfaces (HMI). They struggle with moisture and extreme heat or cold, which can make them unsafe and hard to use. Industries like food and drinks require strong screens that can withstand these challenges. These screens must meet standards like IP66F or NEMA 4X to ensure longevity. Additionally, shared touchscreens present hygiene problems in hospitals and public places. However, new AI and smart computing ideas are creating better options for Human-Machine Interfaces (HMI). These innovative tools improve mobile screens and address issues with tablets or phones.

Key Takeaways

-

Regular touchscreens don’t work well in tough places. This makes them unsafe and hard to use in jobs like healthcare or food.

-

AI tools like voice and hand movements make work safer. They let people use machines without touching them.

-

Small computers make screens cheaper and easier to update. This helps businesses keep up with new needs.

-

AI-powered screens give live data and custom options. They make work simpler and help people make better choices.

-

Jobs like healthcare and factories get big help from AI. These tools create cleaner spaces and safer ways to work.

Problems with Traditional Touchscreen HMIs

Germs on Shared Screens

Shared touchscreens can collect germs and bacteria easily. In places like hospitals, stores, or train stations, many people touch the same screens. This can spread sicknesses quickly. For example, studies show shared screens can carry harmful germs. This is a big problem in healthcare and food industries. Cleaning screens often helps, but it’s hard to do in busy areas. Because of this, we need cleaner and safer screen alternatives.

Hard to See in Bright Light

Touchscreens don’t work well in bright light. Most screens are not bright enough, especially in sunlight. Sunlight-readable screens are brighter, up to 800 cd/m², and have anti-glare features. These screens work better outside but cost more. Many industries can’t afford them. Poor visibility makes regular touchscreens less useful outdoors, like on construction sites or at bus stops.

Trouble in Hands-Free Situations

Touchscreens need you to use your hands, which isn’t always easy. Workers or doctors sometimes need to use machines without touching them. This slows them down and can spread germs in clean areas. Voice commands or gestures are better for hands-free use. These options solve a big problem with touchscreens.

Safety Concerns in Important Workplaces

Safety is very important in jobs using human-machine interfaces (HMIs). Regular touchscreens often fail in critical jobs like factories, planes, or hospitals. These jobs need tools that are precise and reliable, but touchscreens can cause safety problems.

One big issue is accidental touches. In busy places, people might press the wrong button by mistake. For example, in a factory, a worker could stop a machine or start it by accident. This can cause big mistakes or even injuries. Touchscreens don’t give physical feedback, which makes this worse.

Another problem is distractions. Workers like pilots or doctors need to stay focused. Touchscreens make them look away from their work to use the screen. This short distraction can be dangerous, especially in emergencies.

The environment also causes problems. Touchscreens might stop working in very hot or cold places. They also fail when wet. In emergencies like fires or disasters, this can slow down important decisions.

AI-powered tools can fix these problems. Voice commands and gestures let people work without touching screens. This lowers the chance of mistakes. These tools also help workers stay focused while using machines. By solving touchscreen issues, AI makes workplaces safer and more efficient.

Technological Advancements Driving Alternative HMIs

Embedded Computing for Cost-Effective Solutions

Modern embedded computing helps improve human-machine interfaces (HMI) in smart ways. These systems save money by cutting costs and making maintenance easier. Their small size makes them perfect for places with limited space. Businesses use embedded HMIs to work faster and spend less, staying ahead in fast-changing industries.

Tip: Embedded computing is simple to upgrade and adjust, making it useful for changing needs.

Here’s a comparison of PLC-based and PC-based HMIs:

|

Feature |

PLC-Based HMIs |

PC-Based HMIs |

|---|---|---|

|

Processing Power |

Low, handles basic tasks |

High, supports advanced analytics |

|

Usability |

Simple text displays |

Easy-to-use touchscreens |

|

Connectivity |

Limited connections |

Fast Ethernet, supports IoT |

|

Scalability |

Hard to improve |

Easy to upgrade and expand |

These systems link workers to machines, boosting safety and making work smoother. Using embedded computing, companies get better results without spending too much.

AI Enhancements for Smarter Interactions

AI changes how people use HMIs, making them smarter and easier to use. With gestures, people can control machines without touching them, which is safer in risky areas. AI-powered interfaces also learn from users, creating custom experiences that fit their needs.

|

Evidence Type |

Description |

|---|---|

|

Usability Enhancement |

AI makes systems easier and faster to use. |

|

Gesture Control |

Gestures let users work hands-free in dangerous places. |

|

Personalized Interfaces |

AI learns user habits, making systems more personal. |

|

Real-time Monitoring |

IoT and cloud tools help monitor systems in real time. |

|

Industry Applications |

AI tools like dashboards and AR are key in factories and hospitals. |

AI-powered HMIs also show live data, helping workers make quick decisions. These tools improve control and flexibility, working well with modern embedded computing systems.

Flexible Connectivity for Seamless Integration

Flexible connections are key for smooth HMI integration. They allow systems to work together, improving communication and data sharing. In healthcare, flexible connections help doctors and nurses share information, leading to better patient care. Standards like FHIR make sure data is shared correctly, helping teams work together.

In factories, PC-based HMIs with wireless and fast Ethernet connections allow real-time control and steady data flow. This flexibility supports modern automation, making work faster and easier to manage. By using flexible connections, industries can stay ready for the future and adapt to new challenges.

AI-Driven HMI Alternatives

Voice Recognition for Hands-Free Interaction

Voice recognition lets people control machines by speaking. This hands-free method helps workers move easily and work faster. In clean places like hospitals or food factories, it stops germs from spreading. Users give commands without touching screens, keeping things cleaner.

This tool also helps people with physical challenges. They can speak to control devices, making tasks easier for everyone. Voice systems understand different accents and languages, working well in many jobs. These systems connect wirelessly, allowing smooth communication between devices and users.

Gesture Control for Intuitive Usability

Gesture control lets people use machines with hand or body moves. It’s a simple way to work without touching anything. This is helpful in clean or dangerous places where touching isn’t safe.

For example, factory workers can control machines while wearing gloves. This keeps them focused and avoids distractions. Gestures let workers move around and still control devices from far away. This makes it useful in hospitals, factories, and even cars.

Facial Biometrics for Secure and Personalized Access

Facial biometrics use faces to check who someone is. This keeps systems safe by only letting approved people use them.

One example is at Geisinger Medical Center. Patients scan their faces to get services quickly and safely. This saves time and avoids mistakes in identifying people. It also makes work easier for staff and better for patients.

Facial biometrics also make machines adjust to each user. Settings change based on who is using the machine. This makes work faster and more personal for everyone.

Real-World Uses of AI-Powered HMIs

Healthcare: Improving Cleanliness and Safety

AI-powered HMIs are making healthcare cleaner and safer. Voice and gesture controls let workers use devices without touching them. This helps stop germs from spreading in clean areas. Hospitals also use facial recognition to protect patient records and systems.

AI tools help doctors with real-time data and clear visuals. For example:

-

A city hospital cut waiting times by 30% using AI to plan patient flow.

-

A teaching hospital improved recovery rates by using live data for decisions.

These tools make hospitals run better and help patients recover faster. They also keep healthcare spaces safer and more effective.

Cars: Keeping Drivers Safe and Focused

In cars, AI-powered HMIs help drivers stay safe and focused. Drivers can use voice or gestures to control systems without letting go of the wheel. Facial recognition checks if drivers are tired or distracted.

Safety groups are pushing for better tech:

|

Group |

Plan |

How It Helps Drivers |

|---|---|---|

|

Euro NCAP |

Driver Monitoring Systems (DMS) |

Finds tired or distracted drivers |

|

NHTSA |

New Safety Rules |

Promotes driver focus and safety |

These tools, along with wireless tech, make driving safer and reduce crashes.

Factories: Solving Brightness and Work Challenges

Factories often deal with bright lights and tough conditions. AI-powered HMIs solve these problems with smart controls. Workers can use gestures to control machines, even with gloves on. This keeps them safe and efficient.

AI also helps save energy and resources:

-

AI tracks production to adjust schedules for on-time deliveries.

-

It studies energy use to cut waste and lower costs.

Flexible connections make it easy for devices and workers to share data. This keeps work smooth and ready for changes.

The Future of Human-Machine Interfaces

Changing User Experience with Smart Data

Smart data is changing how people use human-machine interfaces (HMI). Predictive tools are a big part of this change. By 2025, over 35% of HMIs will use AI. These systems will predict needs and give helpful suggestions. This makes working with machines easier and smoother.

The HMI market is growing fast.

|

Year |

Market Revenue (USD Billion) |

AI Use (%) |

Auto Sector Revenue (%) |

|---|---|---|---|

|

2023 |

5.2 |

N/A |

N/A |

|

2032 |

10.7 |

N/A |

N/A |

|

2015 |

N/A |

16 |

N/A |

|

2025 |

N/A |

35 |

45 |

These tools help workers make quick and smart choices. This improves safety and work in risky places.

Fixing Problems to Use New HMIs

Using new HMIs means solving some problems first. Knowing what workers need is key to making good designs. Real-time data and clear images help workers act fast. Alarms warn about problems, keeping work safe and following rules.

KEB shows how to do this well. They focus on saving energy and easy-to-use designs. Smart alarms and remote tools mean fewer trips to fix things. Smart systems check data to stop problems before they happen. Sharp screens help workers avoid mistakes. These ideas show how to solve problems and use HMIs better.

Future of HMIs

HMIs will grow a lot in the next few years. By 2025, the market will be worth $6.2 billion. There will be 10 million devices for work and 38 million for home use. This shows more people want wireless and smart tools.

As tech gets better, HMIs will use more AI and IoT. This will make them easier to use and safer. These changes will help people work better with machines in tough places.

Old touchscreen HMIs don’t work well in modern industries. They have problems with cleanliness, ease of use, and safety. These issues make it hard for workers in important jobs. AI-powered systems bring new solutions. They use smart data, wireless tech, and better controls. These tools are more flexible and help workers do their jobs faster.

The future of HMIs is in using smart tech. These tools will make machines easier, safer, and faster to use. By using these new ideas, industries can improve how people and machines work together. This will create a more connected and efficient world.

What is an HMI, and why does it matter?

An HMI, or Human-Machine Interface, helps people control machines. It’s important because it makes tasks easier, safer, and faster in industries like healthcare, cars, and factories.

How does AI make HMIs better?

AI improves HMIs with tools like voice commands and gestures. These features make using machines easier, safer, and more personal. They also fix problems like germs and hard-to-use screens.

Are AI-powered HMIs costly to set up?

AI-powered HMIs may cost more at first. But they save money over time by working better, reducing mistakes, and needing less fixing.

Can AI-based HMIs work in tough conditions?

Yes, AI-based HMIs are built for tough places. They use voice and gestures, so no touching is needed. This works well in heat, wet areas, or bright light.

Which industries gain the most from AI-driven HMIs?

Healthcare, car-making, and factories benefit a lot. These systems improve safety, speed up work, and give live data. They are great for places needing clean and precise tools.

See Also

Improving Smartphone Screens With MAX8647ETE+T Technology

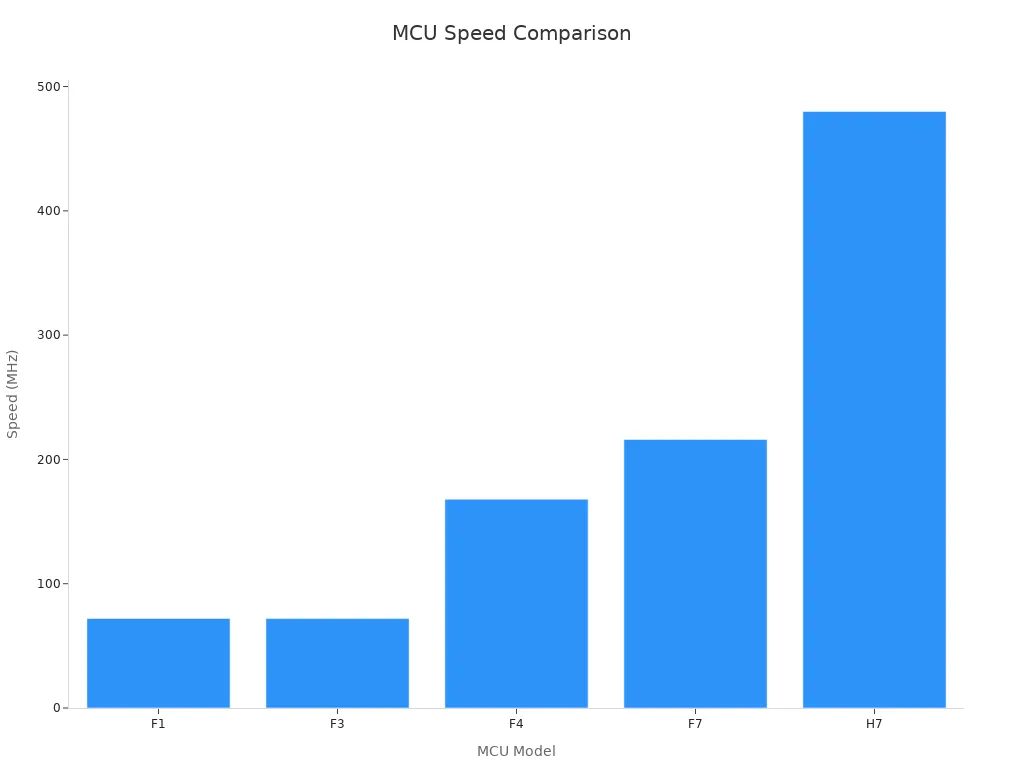

Using STM32F103C8T6 MCUs for Bluetooth Robot Control

Integrating AEAT-8800-Q24 to Boost Robotics Efficiency

Utilizing ATA5824C for Advanced Remote Control Applications

Streamlined Engine Control Solutions With SPC56 Microcontrollers