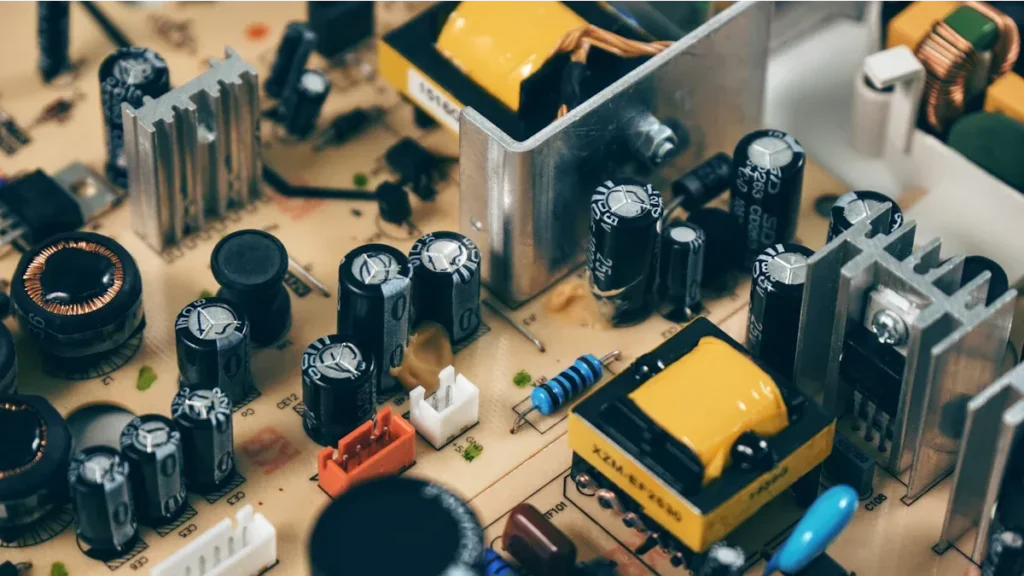

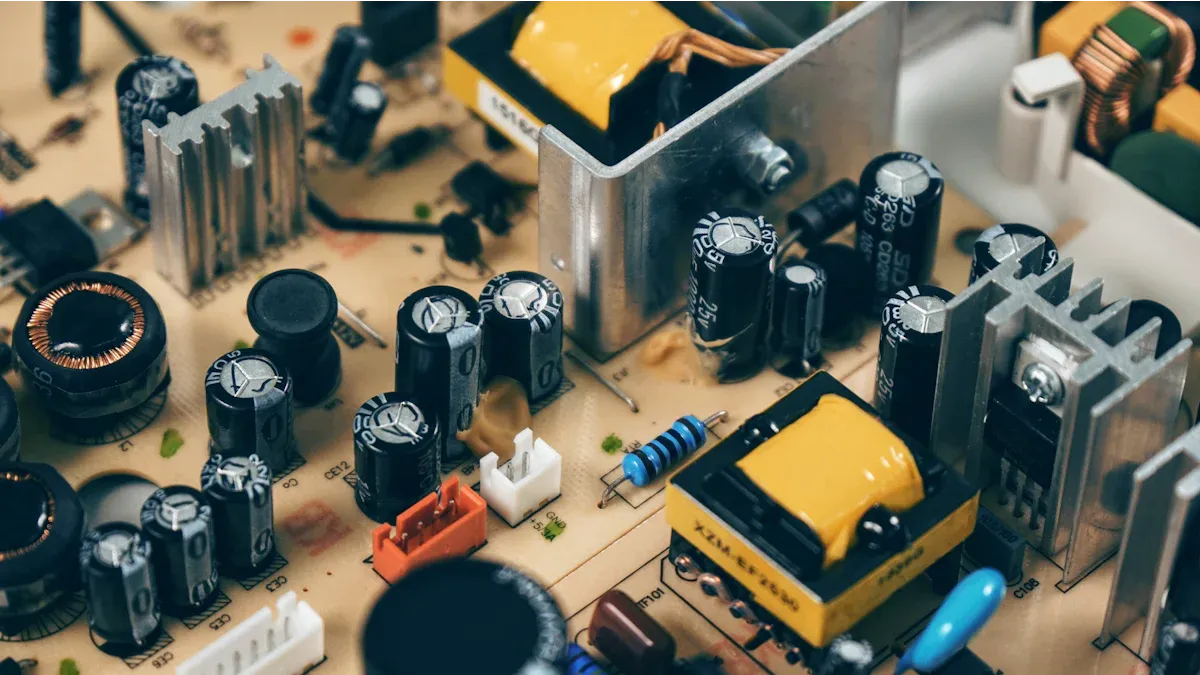

Aluminum Electrolytic Capacitors are essential components in modern electronics, facilitating energy storage, voltage smoothing, and circuit filtering. Constructed with an aluminum anode, a liquid electrolyte, and a thin oxide layer serving as the dielectric, these capacitors achieve high capacitance values, making them indispensable for applications such as power supplies, telecommunications, and automotive systems.

To ensure optimal performance and reliability, understanding their working principles is crucial, especially as advancements prioritize miniaturization and efficiency. With the global market expected to grow from USD 4.46 billion in 2025 to USD 5.38 billion by 2030, leading manufacturers like Nippon Chemi-Con and Rubycon are driving innovation, enhancing the capabilities of Aluminum Electrolytic Capacitors for a wide range of applications.

Key Takeaways

-

Aluminum capacitors store energy and keep voltage steady in electronics.

-

Using them in cooler temperatures makes them last much longer.

-

For every 10°C drop, their life doubles.

-

Picking the right voltage and current limits keeps them working well.

-

Checking them often helps avoid them breaking too soon.

-

New tech, like electric cars and green energy, needs better capacitors.

How Aluminum Electrolytic Capacitors Work

Working principle of electrolytic capacitors

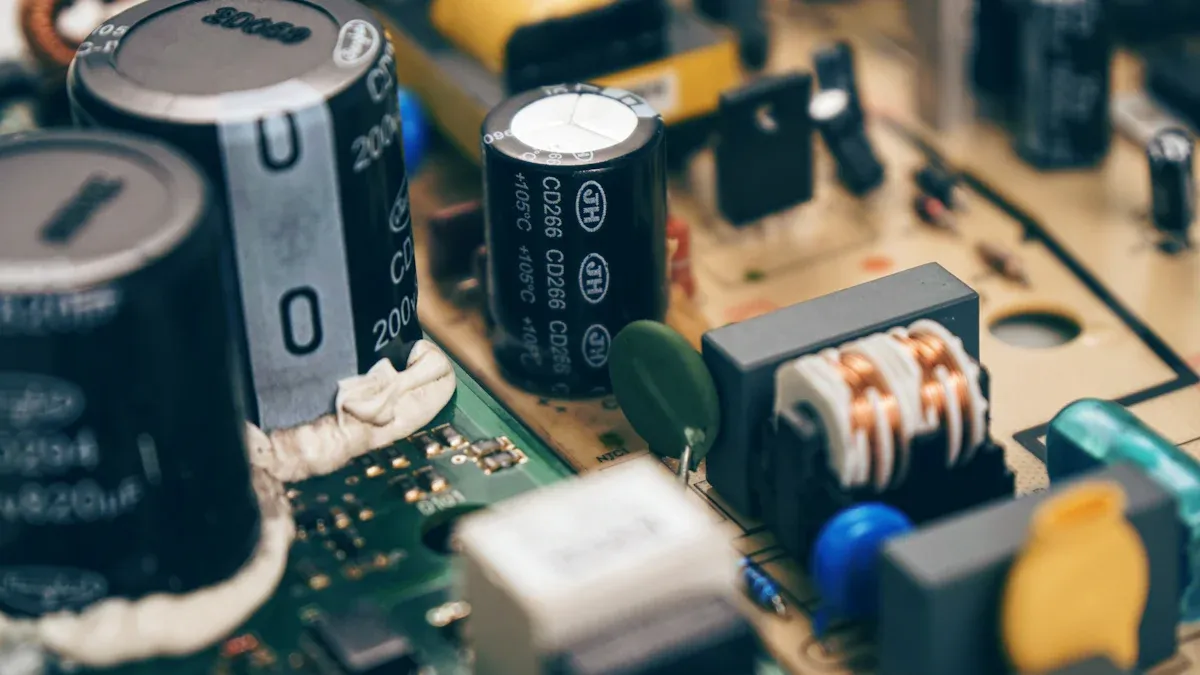

Electrolytic capacitors operate based on the principle of energy storage in an electric field. The aluminum electrolytic capacitor, in particular, relies on its unique construction to achieve high capacitance. The anode, made of aluminum, is etched to increase its surface area. A thin oxide layer forms on the aluminum surface, acting as the dielectric. This oxide layer is critical because it allows the capacitor to store energy efficiently.

The electrolyte, either liquid or solid, surrounds the oxide layer and serves as the cathode. When voltage is applied, the capacitor stores energy by accumulating opposite charges on the anode and cathode. The oxide layer’s self-healing property ensures durability. If the layer sustains damage, electrochemical reactions repair it, maintaining the capacitor’s functionality.

Role of aluminum and electrolyte in energy storage

Aluminum plays a pivotal role in the energy storage process. Its high conductivity and ability to form a stable oxide layer make it ideal for use in electrolytic capacitors. The oxide layer’s thinness enhances capacitance by allowing a larger electric field to form within a compact space. This feature enables aluminum electrolytic capacitors to achieve high capacitance values relative to their size.

The electrolyte complements aluminum by maintaining the oxide layer and facilitating charge transfer. It ensures that the capacitor operates efficiently under varying conditions. Studies comparing different electrolytes reveal their impact on energy efficiency and environmental performance. For instance, capacitors with optimized electrolytes demonstrate lower energy consumption and emissions, highlighting the importance of material selection.

Mechanism of charge storage and energy release

The charge storage mechanism in aluminum electrolytic capacitors involves the separation of charges across the oxide layer. When a voltage is applied, electrons accumulate on the anode, creating a positive charge. Simultaneously, the electrolyte facilitates the movement of ions to the cathode, establishing a negative charge. This separation of charges generates an electric field, storing energy within the capacitor.

Energy release occurs when the capacitor discharges. The stored energy flows back into the circuit, stabilizing voltage and smoothing current fluctuations. This process is essential in applications like power supplies and audio equipment, where consistent performance is critical. The capacitor’s ability to store and release energy efficiently makes it a cornerstone of modern electronics.

Lifespan Calculation of Aluminum Electrolytic Capacitors

Key factors affecting lifespan (temperature, voltage, ripple current)

The lifespan of aluminum electrolytic capacitors depends on several critical factors, including temperature, voltage, and ripple current. These factors directly influence the capacitor’s performance and durability over time.

Temperature plays a significant role in determining the service life of electrolytic capacitors. Higher ambient temperatures accelerate the evaporation of the electrolyte, leading to increased leakage current and reduced lifespan. Studies show that reducing the operating temperature by 10°C can double the capacitor’s lifespan. This relationship highlights the importance of maintaining optimal thermal conditions during operation.

Ripple current also impacts the longevity of electrolytic capacitors. When ripple current flows through the capacitor, it generates heat due to internal resistance. Excessive ripple current can cause overheating, which accelerates electrolyte degradation and shortens the capacitor’s service life. Manufacturers specify maximum ripple current ratings to ensure reliable operation under varying conditions.

Voltage is another crucial factor. Operating a capacitor at or near its rated voltage can stress the oxide layer, increasing leakage current and reducing lifespan. Lowering the applied voltage below the rated value can extend the capacitor’s life expectancy, as it reduces the stress on the dielectric layer.

The following table summarizes the impact of these factors on the lifespan of aluminum electrolytic capacitors:

|

Factor |

Impact on Lifespan |

|---|---|

|

Temperature |

Service life decreases with increased ambient temperature; a reduction of 10°C can double lifespan. |

|

Ripple Current |

Higher ripple currents increase heating, affecting longevity; maximum ripple current specified at max temperature. |

|

Voltage |

Operating at rated voltage impacts lifespan; reduced voltage can extend life expectancy. |

Methods for lifespan calculation

Calculating the lifespan of aluminum electrolytic capacitors involves analyzing their operating conditions and applying manufacturer-provided formulas. Most manufacturers provide a baseline lifespan for their capacitors, typically measured at a specific temperature, voltage, and ripple current.

The most common method for lifespan calculation uses the Arrhenius equation, which relates the capacitor’s lifespan to temperature. For every 10°C decrease in operating temperature, the lifespan doubles. This relationship allows engineers to estimate the capacitor’s service life under different thermal conditions.

Ripple current multipliers also play a role in lifespan calculation. These multipliers adjust the baseline lifespan based on the actual ripple current experienced by the capacitor. For example, if the ripple current exceeds the rated value, the multiplier reduces the estimated lifespan accordingly.

Voltage derating is another technique used in lifespan calculation. By operating the capacitor at a voltage lower than its rated value, engineers can extend its service life. Combining these methods provides a comprehensive approach to estimating the lifespan of electrolytic capacitors.

Importance of maintenance and proper usage

Proper maintenance and usage are essential for maximizing the lifespan of aluminum electrolytic capacitors. Regular inspection of operating conditions, such as temperature and ripple current, helps identify potential issues before they cause significant damage. Ensuring that the capacitor operates within its specified voltage and ripple current limits prevents premature failure.

Storage conditions also affect the longevity of electrolytic capacitors. Prolonged exposure to high temperatures or humidity can degrade the electrolyte, increasing leakage current and reducing performance. Storing capacitors in a cool, dry environment preserves their quality and extends their shelf life.

In applications where capacitors are subjected to high ripple currents or elevated temperatures, selecting components with higher ratings or enhanced thermal stability ensures reliable operation. Following these practices not only extends the lifespan of the capacitor but also improves the overall reliability of the electronic system.

Structure and Characteristics of Aluminum Electrolytic Capacitors

Internal structure (anode, cathode, electrolyte)

The internal structure of aluminum electrolytic capacitors consists of three primary components: the anode, cathode, and electrolyte. The anode, made of etched aluminum foil, provides a large surface area to enhance capacitance. A thin oxide layer forms on the anode, serving as the dielectric. This oxide layer is crucial for energy storage and exhibits self-healing characteristics, ensuring durability.

The cathode is formed by the electrolyte, which can be liquid, gel, solid, or hybrid. Each type of electrolyte offers unique performance characteristics. For instance, hybrid polymer electrolytes provide superior performance in high-capacity applications. The electrolyte not only acts as the cathode but also maintains the stability of the oxide layer.

Aluminum electrolytic capacitors are available in various construction styles, as shown below:

|

Construction Style |

Description |

|---|---|

|

SMDs (V-chip) |

Surface mounting on printed circuit boards |

|

Radial lead terminals |

Vertical mounting on printed circuit boards |

|

Axial lead terminals |

Horizontal through-hole mounting on printed circuit boards |

|

Radial pin terminals |

Snap-in for power applications |

|

Press-fit terminals |

For secure connections in various applications |

|

Large screw terminals |

For power applications |

Characteristics (capacitance, voltage rating, ESR)

Aluminum electrolytic capacitors are known for their high capacitance values, which allow them to store significant amounts of energy. Capacitance depends on the surface area of the anode and the thickness of the oxide layer. These capacitors also feature a wide range of voltage ratings, making them suitable for various applications.

Equivalent Series Resistance (ESR) is another critical characteristic. It measures the internal resistance of the capacitor, affecting its efficiency in high-frequency applications. Modern designs focus on reducing ESR to improve performance.

Advantages and limitations

Aluminum electrolytic capacitors offer several advantages:

-

High energy density enables compact designs.

-

Cost-effective solutions for energy storage.

-

Improved ESR stability enhances performance.

-

Longer lifespan under proper operating conditions.

-

Better performance in high-humidity environments.

However, they also have limitations:

-

Increased DC leakage can affect efficiency.

-

Sensitivity to environmental factors like temperature.

-

Higher price points for advanced designs.

Despite these limitations, their benefits make them indispensable in modern electronics.

Application Scenarios for Aluminum Electrolytic Capacitors

Use cases in electronics (power supplies, audio equipment)

Aluminum electrolytic capacitors play a vital role in electronics, particularly in power supplies and audio equipment. Their high energy density and cost-effectiveness make them ideal for bulk applications. In power supplies, these capacitors smooth rectified voltages and filter noise, ensuring stable operation. For audio equipment, they enhance sound quality by stabilizing voltage and reducing distortion.

The equivalent circuit of electrolytic capacitors includes parameters like equivalent series resistance (ESR) and capacitance, which vary with frequency and temperature. Understanding these parameters is crucial for optimizing designs in switch-mode power supplies and audio systems. Accelerated aging tests have validated their reliability, with failure rates ranging from 0.5 to 20 FIT, depending on voltage ratings.

|

Application Area |

Advantages of Aluminum Electrolytics |

|---|---|

|

Power Electronics |

Higher energy storage density compared to standard film capacitors. |

|

Automotive Applications |

Better ripple-current rating at elevated temperatures. |

|

Cost-sensitive Applications |

More economical in commodity off-line power supplies. |

Industrial applications (DC-Link capacitors, inverters)

In industrial settings, aluminum electrolytic capacitors are indispensable for DC-Link capacitors and inverters. These components stabilize voltage fluctuations and handle high ripple currents, ensuring efficient energy transfer. Their ability to operate under high temperatures and maintain low ESR makes them suitable for demanding environments.

Technical performance data highlights their capabilities. For instance, DC-Link capacitors exhibit a capacitance of 450 µF with an ESR of 4.5 mΩ or less, supporting ripple currents up to 60 A rms. These features meet the requirements for miniaturization, high current, and high-frequency applications. Reliability-oriented designs and condition monitoring further enhance their performance in industrial systems.

|

Metric |

Value |

|---|---|

|

Capacitance |

0.46 µF/cm³ |

|

Dielectric Loss |

0.65% |

|

Dielectric Breakdown Voltage |

1450 V to 1650 V |

|

Total Capacitance for Module |

450 µF |

|

Equivalent Series Resistance |

4.5 mΩ or less |

|

Allowed Ripple Current |

60 A rms |

Emerging applications in modern technology

Emerging technologies are driving new applications for aluminum electrolytic capacitors. The rise of electric vehicles has increased the demand for efficient energy storage solutions. Renewable energy systems, such as solar and wind, rely on these capacitors for effective power management. Miniaturization trends in electronics also push for compact and lightweight designs, making aluminum electrolytic capacitors an ideal choice.

These capacitors are crucial for managing power in smart and connected devices. Their small size and high energy density enable their use in modern gadgets. As renewable energy adoption grows, aluminum electrolytic capacitors will play a key role in energy storage systems, ensuring sustainability and efficiency.

-

Aluminum electrolytic capacitors are essential for renewable energy systems like solar and wind.

-

Their compact size supports miniaturization in modern electronics.

-

They provide efficient energy storage for electric vehicles and smart devices.

Selection Criteria for Aluminum Electrolytic Capacitors

Factors to consider (voltage, capacitance, size)

Selecting the right aluminum electrolytic capacitors requires careful consideration of voltage, capacitance, and size. Voltage ratings determine the maximum voltage the capacitor can handle without failure. Operating below the rated voltage enhances reliability and extends lifespan. For instance, the UVR1E471MPD1TD capacitor, with a capacitance of 470 µF and a peak current limit of 550 mA, suits applications needing higher capacitance and current handling.

Capacitance defines the energy storage capacity of the capacitor. Applications requiring stable voltage and energy storage benefit from higher capacitance values. However, physical size often limits capacitance. Compact designs, like the UVR1E470MDD capacitor with a 5 mm diameter and 11 mm length, are ideal for space-constrained environments. Additionally, bulk purchasing options, such as factory packs of 6000 units, provide cost advantages for large-scale projects.

Matching specifications to application needs

Matching capacitor specifications to application requirements ensures optimal performance. Aluminum electrolytic capacitors excel in applications demanding high capacitance and energy density. For power supplies, selecting capacitors with low ESR and high ripple current ratings improves efficiency. In audio equipment, capacitors with excellent temperature characteristics and low acoustic noise enhance sound quality.

The table below highlights key characteristics to consider during application selection:

|

Characteristic |

Rating |

|---|---|

|

ESR |

Good |

|

Temperature characteristics |

Excellent |

|

DC bias characteristics |

Excellent |

|

High-frequency compatibility |

Good |

|

Voltage ratings |

Excellent |

|

Size |

Excellent |

|

Acoustic noise |

Excellent |

|

Long life |

Excellent |

|

Failure modes |

Short |

Ensuring reliability and performance

Ensuring the reliability and performance of aluminum electrolytic capacitors involves monitoring critical parameters. Ambient temperature, ripple current, and ESR significantly impact longevity. Real-time monitoring of hotspot temperature and ripple current helps maintain mechanical integrity and prevents premature failure.

Aging indicators, such as increased ESR and decreased capacitance, signal the need for replacement. Multi-lifetime models provide accurate predictions by considering these factors. Maintaining mechanical integrity through proper installation and avoiding excessive stress ensures long-term performance.

Aluminum electrolytic capacitors remain essential for modern electronics. Their versatility and reliability make them indispensable for diverse applications, from power supplies to industrial systems. Proper selection and maintenance maximize their potential and ensure system integrity.

Market Trends for Aluminum Electrolytic Capacitors

Demand growth in electronics and technology

The demand for aluminum electrolytic capacitors continues to grow due to advancements in electronics and technology. These capacitors are essential in industries like automotive, renewable energy, and industrial automation. The global market for hybrid polymer aluminum electrolytic capacitors is projected to expand from $2.5 billion in 2025 to $4.8 billion by 2033, reflecting a compound annual growth rate (CAGR) of 8%. This growth is driven by the increasing adoption of hybrid and electric vehicles, which require high-performance capacitors for energy storage and power management.

Industrial equipment, particularly in automation and robotics, also contributes significantly to this market expansion. Renewable energy technologies, such as solar inverters and wind turbines, further boost the demand for electrolytic capacitors. These applications rely on the capacitors’ ability to handle high ripple currents and operate efficiently under varying conditions.

Innovations by manufacturers like Nippon Chemi-Con and Rubycon

Leading manufacturers, including Nippon Chemi-Con and Rubycon, play a pivotal role in advancing aluminum electrolytic capacitor technology. These companies focus on improving performance metrics such as capacitance, equivalent series resistance (ESR), and thermal stability. For example, Nippon Chemi-Con has developed capacitors with enhanced ripple current ratings and extended lifespans, catering to the needs of high-demand applications.

The table below highlights some prominent manufacturers driving innovation in the electrolytic capacitor market:

|

Manufacturer |

|---|

|

Nippon Chemi-Con Corporation |

|

Rubycon Corporation |

|

Nichicon Corporation |

|

Panasonic Corporation |

|

Vishay Intertechnology Inc. |

|

TDK Electronics AG |

These companies invest heavily in research and development to meet the evolving requirements of modern electronics. Their innovations ensure that aluminum electrolytic capacitors remain reliable and efficient in diverse applications.

Future outlook and challenges

The future of aluminum electrolytic capacitors looks promising, with the market size expected to grow from $13.6 billion in 2024 to $27.9 billion by 2033, at a CAGR of 7.88%. Rising demand from sectors like medical, automotive, and telecommunications will drive this growth. The shrinking size of electrical equipment and the need for government and private investments also present opportunities for market expansion.

However, the industry faces challenges such as the need for sustainable materials and the increasing complexity of electronic systems. Manufacturers must address these issues to maintain the reliability and performance of electrolytic capacitors. Despite these challenges, the growing adoption of renewable energy and electric vehicles ensures a bright future for this technology.

Aluminum electrolytic capacitors remain vital in modern electronics due to their high energy density and reliability. Their ability to handle demanding applications, such as power supplies and industrial systems, underscores their importance. Companies continue to invest in research and development, driving innovations that enhance performance and operational reliability.

The market for these capacitors is projected to grow from USD 4.60 billion in 2024 to USD 6.34 billion by 2030, reflecting a compound annual growth rate of 5.50%. This growth highlights their expanding role in emerging technologies, including renewable energy and electric vehicles. Failure analysis and improved failure modes are key areas of focus, ensuring these components meet the evolving demands of the electronics industry.

As technology advances, aluminum electrolytic capacitors will play an even greater role in shaping the future of energy-efficient and sustainable systems.

What is the primary function of aluminum electrolytic capacitors?

Aluminum electrolytic capacitors store electrical energy and release it when needed. They stabilize voltage, filter noise, and smooth current in electronic circuits. These functions make them essential in power supplies, audio equipment, and industrial systems.

How does temperature affect the lifespan of these capacitors?

Higher temperatures accelerate electrolyte evaporation, reducing the capacitor’s lifespan. Operating at lower temperatures can double the lifespan for every 10°C decrease. Proper thermal management ensures longer service life and reliable performance.

Can aluminum electrolytic capacitors handle high ripple currents?

Yes, they can handle high ripple currents, but excessive ripple generates heat, which may degrade the capacitor. Manufacturers specify maximum ripple current ratings to ensure safe operation. Selecting capacitors with higher ripple current ratings improves durability.

What are the advantages of using aluminum electrolytic capacitors?

These capacitors offer high energy density, cost-effectiveness, and excellent performance in high-humidity environments. They also provide stable capacitance and low ESR, making them suitable for various applications, including renewable energy systems and automotive electronics.

How do you select the right capacitor for your application?

Consider voltage rating, capacitance, and size. Match these specifications to the application’s requirements. For example, low ESR capacitors suit high-frequency circuits, while high-capacitance models work well in energy storage systems. Proper selection ensures reliability and efficiency.

See Also

Understanding MC9S12DJ256MFUE Features for Automotive Use

Unveiling LPQ252-CEF for Optimal Power Control

Reasons to Select Coilcraft XPL2010 for VRM Solutions

Harnessing AD74413RBCPZ for Enhanced Process Management

IRF820: A Versatile N-Channel MOSFET for Power Applications