ARTESYN stands as a leader in the LED driver market, delivering innovation and reliability. The ARTESYN LCM4000HV series LED driver modules offer a powerful solution for industrial lighting retrofits. Each module provides up to 4 kW output and reaches 95% efficiency, helping facilities save energy and reduce costs. Centralized power and a rack-mount design simplify installation and maintenance. Real-world data shows initial capital cost savings up to 35% and annual operational savings near 20%.

|

Savings Type |

Percentage |

|---|---|

|

Initial capital cost savings |

Up to 35% |

|

Annual operational cost savings |

Approximately 20% |

Key Takeaways

-

ARTESYN LCM4000HV LED driver modules deliver up to 95% efficiency and can reduce energy costs by about 20% annually.

-

The modules support a wide input voltage range and centralized power design, which lowers wiring costs and simplifies installation.

-

Hot plug replacement and modular rack-mount design make maintenance fast and easy without shutting down the system.

-

Facility managers should assess existing lighting systems carefully and use simulation tools to predict energy savings before retrofitting.

-

Integrating smart controls with these modules boosts energy savings and allows flexible lighting management for industrial buildings.

Why Choose This Series

Key Advantages

ARTESYN has earned global recognition for its innovation and reliability in power solutions. The ARTESYN LCM4000HV series LED driver modules stand out due to their advanced design and technical features. These modules deliver high efficiency, robust protection, and flexible control options. Facility managers can rely on their centralized power source and modular scalability for large-scale lighting projects.

|

Feature/Specification |

Details/Value |

|---|---|

|

Power Density |

38 Watts per cubic inch |

|

Output Power |

4000 W |

|

Efficiency |

Up to 95.2% |

|

Input Voltage Range |

187-264 VAC; 311-528 VAC |

|

Power Factor |

0.98 @ 100% load at 208 VAC |

|

Harmonics Compliance |

Meets IEC 61000-3-12 |

|

Safety Standards |

DLC 2.1, Industrial Safety |

|

Warranty |

5 years |

|

Communication |

Digital and Analog (MODBus) |

|

Cooling |

Smart variable speed fans, dust control |

|

Output Voltage Range |

100 VDC to 300 VDC |

|

Output Current |

Up to 16 Amps |

|

Mounting |

19” 1U rack mount shelf, hot plug replacement |

The ARTESYN LCM4000HV series LED driver modules offer several key advantages:

-

Wide AC input range supports single or three-phase power, increasing compatibility.

-

Centralized current source provides flicker-free lighting and reduces wiring costs.

-

Hot plug replacement and modular design simplify maintenance.

-

Over-current, over-temperature, and over-voltage protection ensure safety.

-

Digital and analog dimming controls allow flexible lighting management.

-

RoHS compliance and certifications support environmental responsibility.

Note: Real-world case studies show up to 35% savings on initial capital costs and about 20% savings on annual operational costs compared to traditional drivers.

Industrial Applications

The ARTESYN LCM4000HV series LED driver modules power a wide range of industrial and commercial lighting systems. These modules work well in warehouses, factories, and horticulture facilities. They also support street and outdoor lighting projects. Their high efficiency and centralized design help reduce energy consumption and maintenance needs.

|

Feature / Metric |

Details / Values |

|---|---|

|

Power Supply Model |

LCM4000HV series, 4 kW configurable power supply |

|

Efficiency |

Up to 95% |

|

Input Voltage Range |

208 VAC to 600 VAC, single or three-phase |

|

Output Voltage Range |

100 VDC to 300 VDC, flicker-free |

|

Output Current |

Up to 16 A |

|

Mounting |

19″ 1U rack, up to 12 kW per rack |

|

Maintenance |

Hot plug replacement |

|

Power Quality Improvements |

Improved PF, reduced THD, balanced power line |

|

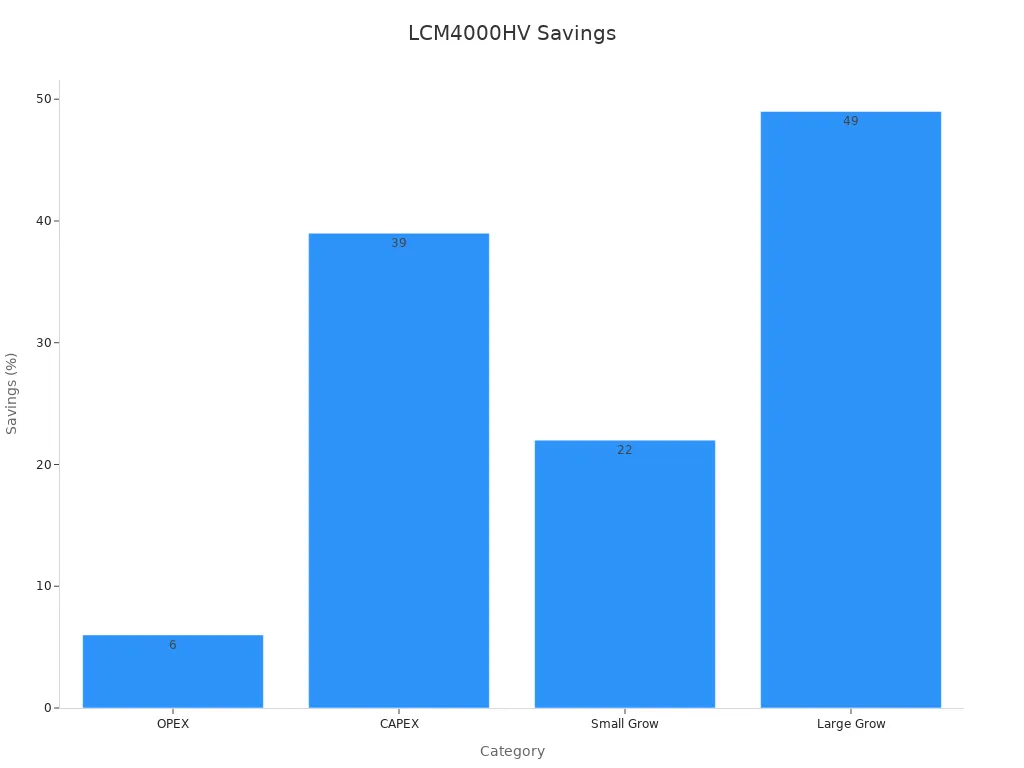

Cost Savings (OPEX) |

Nearly $70,000 annually (6%) |

|

Cost Savings (CAPEX) |

About $169,135 (39%) |

|

Additional Benefits |

Digital control, reduced repair time, lower shipping costs |

Facility managers in industrial, commercial, and outdoor environments choose these modules for their reliability, energy savings, and ease of integration. The ARTESYN LCM4000HV series LED driver modules help organizations achieve sustainability goals while maintaining high performance.

ARTESYN LCM4000HV Series LED Driver Modules Retrofit Guide

Assessing Existing Systems

Facility managers begin a retrofit by evaluating the current lighting system. They check the type and number of luminaires, measure lumen output, and note color temperature and beam angle. They also review energy efficiency and system compatibility. A comprehensive monitoring protocol helps track energy use, lighting quality, costs, and user satisfaction. Many experts recommend using simulation tools, such as EnergyPlus and Monte Carlo methods, to predict energy savings. These tools show that retrofits can reduce energy use by 43% to 65% compared to older systems. This careful assessment ensures the new system will meet performance and cost goals.

Tip: Document all existing wiring, breaker panels, and control systems before starting the retrofit. This step helps avoid compatibility issues later.

Selecting Modules

Selecting the right ARTESYN LCM4000HV series LED driver modules depends on the size and needs of the facility. Each module delivers 4000 W of power and supports a wide input voltage range from 208 VAC to 600 VAC, single or three-phase. The modules provide flicker-free current output, which is ideal for both industrial and horticultural lighting. Facility managers should consider the total lighting load, the number of luminaires, and the desired control features. Integration with the LCM12K mounting shelf allows for scalable system design. Product datasheets and case studies offer guidance on operational parameters and energy efficiency benefits.

-

Bulk power distribution increases efficiency and reliability.

-

Centralized power supply reduces installation and maintenance costs.

-

Flicker-free current source output ensures stable lighting.

-

Modules support advanced digital and analog controls for flexible lighting management.

Installation Steps

A step-by-step approach ensures a smooth retrofit process. The following table outlines key installation steps and their benefits:

|

Step |

Description |

|---|---|

|

Planning |

Coordinate with engineers to schedule system shutdowns and minimize downtime. |

|

Preparation |

Use pre-fabricated wiring and mounting hardware to speed up installation. |

|

System Shutdown & Isolation |

Apply lock-out/tag-out procedures to ensure safety before working on electrical systems. |

|

Module Installation |

Mount ARTESYN LCM4000HV series LED driver modules in a 19” rack and connect to AC input. |

|

Wiring & Integration |

Connect output wiring to luminaires and integrate with lighting controls. |

|

Testing & Commissioning |

Test the system for correct operation, check for flicker-free output, and verify controls. |

|

System Restart |

Power up the system and monitor performance to ensure all modules operate as expected. |

This process follows industry standards such as PAS 2030 and PAS 2035, which focus on quality management and thorough project evaluation. The rack-mount design and hot plug replacement features of the ARTESYN LCM4000HV series LED driver modules make installation and maintenance efficient.

Note: Digital control eliminates the need for extra dimming wires, making integration with smart lighting systems easier.

Safety Tips

Safety remains a top priority during any retrofit. The ARTESYN LCM4000HV series LED driver modules meet UL 924 standards for emergency lighting and comply with California Title 20 energy-efficiency requirements. They are rated for dry and damp locations, supporting safe use in various environments.

-

Always follow lock-out/tag-out procedures before working on electrical systems.

-

Use only certified personnel for installation and maintenance.

-

Check that all modules and wiring meet local electrical codes.

-

Install test switches and visible charging indicators for easy maintenance checks.

-

Place power supplies in remote locations when possible to avoid harsh environments.

Some modules feature IP67 ingress protection, which guards against dust and water. The hot-swap design reduces the need for climbing or working at heights, lowering the risk of accidents. These safety measures help protect both workers and building occupants.

Maximizing Efficiency and Performance

Optimizing Settings

Facility managers can improve energy savings by adjusting driver settings to match the needs of each lighting zone. Studies in energy consumption and performance show that optimizing control strategies, such as adjusting speed profiles and operating modes, leads to better efficiency. For example:

-

Edrén et al. (2019) found that using advanced control strategies can reduce energy use.

-

Ding and Jin (2018) showed that changing operational profiles results in measurable energy savings.

-

Bentaleb et al. (2022) highlighted the value of optimizing control methods to minimize energy use.

-

Kesting et al. (2010) and Wang and Rakha (2017) demonstrated that fine-tuning system behavior improves overall efficiency.

Facility managers should review manufacturer guidelines and use built-in digital controls to set output levels, dimming schedules, and power modes. Regularly reviewing and updating these settings ensures the lighting system operates at peak efficiency.

Smart Controls Integration

Integrating smart control systems with centralized power solutions unlocks further efficiency gains. The LumaDrive system, for example, uses a centralized power architecture that simplifies installation and reduces the need for multiple control points. Real-world data shows that combining smart controls with centralized drivers can cut capital costs by up to 35% and lower operational expenses by about 20%. In vertical farming, the GROWINSIGHT™ IoT platform works with centralized drivers to reduce energy losses and HVAC costs. Intelligent lighting schedules and cloud-based monitoring help optimize energy use, even during network outages. Compatibility with various controllers and PLCs allows flexible integration, making it easier to adapt to changing facility needs.

Maintenance Best Practices

Regular maintenance keeps lighting systems reliable and efficient. Maintenance records should include equipment identification, service dates, actions taken, and technician notes. Best practices involve:

-

Standardizing log formats and automating record-keeping.

-

Assigning clear responsibilities for maintenance tasks.

-

Reviewing logs to spot patterns and schedule preventive work.

-

Using IoT sensors for real-time monitoring and early fault detection.

-

Training staff on new technologies and safety procedures.

Tracking key metrics like Mean Time Between Failures (MTBF) and Mean Time to Repair (MTTR) helps managers evaluate system performance. Continuous improvement based on maintenance data ensures long-term reliability and cost savings.

Troubleshooting and Solutions

Compatibility Issues

Facility managers often encounter compatibility issues when retrofitting lighting systems. Existing luminaires and wiring may not match new driver modules. Some older fixtures use different voltage or current requirements. In these cases, managers should review all technical specifications before installation. They can consult product datasheets and use simulation tools to predict system performance. When uncertainty arises, contacting the manufacturer or a qualified engineer helps ensure a proper match. Local authorities can also provide guidance on compliance with electrical codes and standards. Clear documentation of the existing system supports a smooth transition to new technology.

Installation Challenges

Retrofit projects present practical challenges on site. Dust management becomes important, especially in active industrial environments. Installers sometimes face conflicts between safety equipment and work conditions, such as masks causing glasses to fog. Many installers learn on the job, so pairing less experienced workers with skilled professionals improves outcomes. Communication gaps between inspectors and installers can slow progress. To address these issues:

-

Use pre-fabricated wiring and mounting hardware to reduce time on site.

-

Assign experienced installers to mentor new team members.

-

Schedule regular meetings to discuss site-specific adaptations.

-

Encourage open communication between inspectors and installation teams.

Access to clear, locally relevant information helps installers make informed decisions. Local authorities can act as trusted sources for retrofit guidance, while national policies support consistent messaging.

Ensuring Reliability

Long-term reliability depends on robust design and proactive maintenance. The minimum MTBF rating of 200,000 hours for these driver modules demonstrates strong performance over time. Variable-speed smart fans with dust control keep components cool and clean, reducing wear. Hot-swappable modules allow for quick replacement without shutting down the system. Centralized power supply architecture supports continuous operation, even in large-scale applications. Intelligent monitoring platforms, such as IoT-based systems, enable real-time scheduling and local control during network outages. Compliance with industry standards ensures ongoing reliability and performance.

Tip: Maintain detailed service records and schedule preventive maintenance to maximize system uptime and efficiency.

Retrofitting with ARTESYN LCM4000HV series LED driver modules brings clear advantages for industrial buildings. Facility managers see up to 35% lower capital costs and about 20% less in yearly operating expenses, as shown by real-world data. The modular design and high voltage operation reduce wiring costs and boost efficiency. Studies show energy use can drop by as much as 65% after a retrofit. These benefits make the LCM4000HV series a smart choice for reliable, cost-effective lighting upgrades. Facility teams should explore ARTESYN resources for their next project.

What input voltage range does the ARTESYN LCM4000HV series support?

The ARTESYN LCM4000HV series supports a wide input voltage range from 208 VAC to 600 VAC. This flexibility allows facility managers to use the modules in many industrial and commercial settings.

Can these LED driver modules work with smart lighting controls?

Yes, the LCM4000HV series offers both digital and analog control options. Facility managers can integrate these modules with smart lighting systems, including MODBus and other popular protocols, for advanced energy management.

How does the centralized power design improve efficiency?

Centralized power reduces wiring complexity and energy losses. This design also simplifies maintenance and supports flicker-free lighting, which helps improve both efficiency and lighting quality in large facilities.

Are the ARTESYN LCM4000HV modules suitable for outdoor use?

Many modules in the LCM4000HV series feature IP67 ingress protection. This rating means they resist dust and water, making them suitable for outdoor and harsh industrial environments.

See Also

ARTESYN NPT42-M Drives Efficiency In Industrial Automation

Explore LPQ252-CEF To Optimize Power Management Solutions

Integrating AEAT-8800-Q24 To Boost Robotics Performance

Three Methods ATIC83E2 Improves Industrial Automation Systems

Complete Guide To Using AD620AN In TV Power Systems