Bridge Rectifiers Explained: Principles, Applications, and FAQs

A bridge rectifier is a crucial component in modern electronics, designed to convert alternating current (AC) into direct current (DC). This process supports countless devices requiring stable DC power, from household appliances to industrial machinery. The growing demand for renewable energy, electric vehicles, and automated systems has amplified the importance of these rectifiers. Their compact designs and high efficiency meet the needs of miniaturized devices and advanced technologies. Bridge Rectifier distributors play a key role in ensuring access to high-quality components for diverse applications.

Key Takeaways

Bridge rectifiers change AC into DC, which powers devices and charges batteries.

Four diodes in a bridge setup help current flow steadily, using both parts of the AC cycle.

Capacitors and other methods smooth out voltage changes, giving steady DC power for delicate electronics.

Choosing the right bridge rectifier means checking voltage and current limits to avoid overheating and keep it working well.

Bridge rectifiers are useful in many things, like home gadgets and big machines, improving how they work.

Principles of Bridge Rectifiers

How Does a Bridge Rectifier Work?

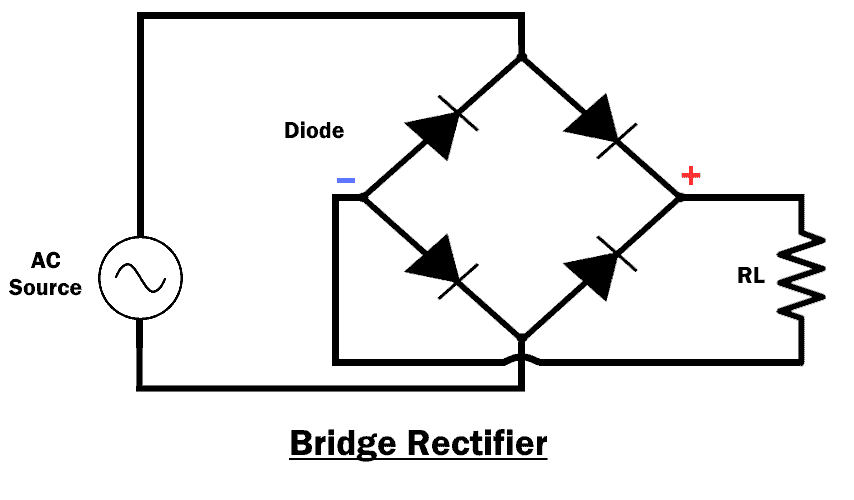

A bridge rectifier converts alternating current (AC) into direct current (DC) using a diode bridge configuration. This circuit consists of four rectifier diodes arranged in a square-like pattern. The design ensures that current flows in one direction through the load, regardless of the polarity of the AC input. During the positive half-cycle of the AC waveform, two diodes conduct, allowing current to pass through the load. In the negative half-cycle, the other two diodes conduct, maintaining the same direction of current flow. This mechanism enables the rectifier to utilize both halves of the AC cycle, resulting in a pulsating DC output.

The diode bridge configuration is a key innovation in current rectification. It maximizes efficiency by converting both halves of the AC waveform into usable DC power.

The Role of Diodes in Rectification

Rectifier diodes play a critical role in bridge rectifiers. These semiconductor devices allow current to flow in one direction while blocking it in the opposite direction. This property is essential for converting AC into DC. In a bridge rectifier, the diodes work in pairs to control the flow of current during each half-cycle of the AC input. For example:

During the positive half-cycle, diodes D1 and D2 conduct, directing current through the load.

During the negative half-cycle, diodes D3 and D4 conduct, ensuring the current direction remains consistent.

This arrangement ensures continuous and efficient rectification, making diode bridges indispensable in modern electronics.

Pulsating DC Output and Smoothing Techniques

The output of a bridge rectifier is a pulsating DC signal. While this signal is unidirectional, it contains fluctuations or ripples due to the alternating nature of the input. Smoothing techniques are employed to reduce these ripples and achieve a stable DC output. Capacitors are commonly used for this purpose. They charge during the peaks of the pulsating DC signal and discharge during the troughs, effectively leveling the voltage.

Filtering components, such as capacitors, eliminate unwanted signal waves.

Capacitors reduce voltage fluctuations, ensuring a more constant DC level.

Advanced circuits may include inductors or voltage regulators for further refinement.

These techniques are vital for applications requiring steady DC power, such as powering sensitive electronic devices or charging batteries.

Comparing Bridge Rectifiers with Other Rectifiers

Bridge Rectifier vs. Half-Wave Rectifier

Bridge rectifiers outperform half-wave rectifiers in several key areas. Half-wave rectifiers only utilize one half of the AC cycle, while bridge rectifiers use both halves. This difference results in higher efficiency and a more consistent DC output for bridge rectifiers. Additionally, the ripple factor, which measures the fluctuations in the DC output, is significantly lower in bridge rectifiers. This makes them more suitable for applications requiring stable power.

Key differences include:

Efficiency: Bridge rectifiers achieve higher efficiency by utilizing the full AC waveform.

Ripple Factor: Bridge rectifiers produce a smoother DC output with fewer fluctuations.

AC Utilization: Half-wave rectifiers waste half of the AC cycle, while bridge rectifiers maximize its use.

Advantage | Bridge Rectifier | Half-Wave Rectifier |

|---|---|---|

Efficiency | Higher | Lower |

Ripple Factor | Lower | Higher |

Utilization of AC Cycle | Both halves | One half |

Bridge Rectifier vs. Full-Wave Rectifier

Bridge rectifiers and full-wave rectifiers share similarities, as both utilize the entire AC waveform. However, their designs differ. Full-wave rectifiers typically require a center-tapped transformer, while bridge rectifiers do not. This makes bridge rectifiers more compact and cost-effective. Both types deliver a higher average DC output compared to half-wave rectifiers, but bridge rectifiers are often preferred for their simpler design.

Metric | Half-Wave Rectifier | Full-Wave Rectifier |

|---|---|---|

Average DC Output Voltage | Lower | Higher (0.637Vmax) |

Ripple Frequency | Same as input | Double the input |

Ripple Factor | ~1.21 | Lower (more stable) |

Efficiency | Lower | Higher |

Transformer Utilization | Lower | Higher |

Efficiency and Ripple Voltage Comparison

Bridge rectifiers excel in efficiency and ripple voltage performance. By using both halves of the AC waveform, they achieve higher efficiency compared to half-wave rectifiers. The ripple factor is also lower, resulting in a smoother DC output. Full-wave rectifiers, which replenish the capacitor twice as often, further reduce ripple voltage. For example, ripple voltage can drop from 4.4V in a half-wave rectifier to 2V in a full-wave rectifier. This improvement ensures a more stable DC supply, which is essential for sensitive electronic devices.

Bridge rectifiers combine efficiency and simplicity, making them a versatile choice for modern electronics.

Applications of Bridge Rectifiers

Bridge rectifiers play a vital role in modern electronics, powering a wide range of devices and systems. Their ability to efficiently convert AC to DC makes them indispensable in various applications, from household gadgets to industrial machinery.

DC Power Supply Systems

Bridge rectifiers are the backbone of DC power supply systems. They convert the alternating current from power outlets into direct current, which is essential for operating electronic devices. This process ensures a steady and reliable power source for equipment like televisions, laptops, and desktop computers.

In consumer electronics, bridge rectifiers are often paired with filtering components to reduce ripple voltage, providing a smooth DC output. This combination enhances the performance and longevity of devices by protecting sensitive circuits from power fluctuations.

Tip: When designing DC power supplies, selecting a bridge rectifier with appropriate voltage and current ratings ensures optimal performance and prevents overheating.

A wide range of industries relies on bridge rectifiers for stable DC power. The table below highlights their diverse applications:

Industry/Application | Description |

|---|---|

Consumer Electronics | Bridge rectifiers convert AC from power outlets to DC for devices like TVs and laptops. |

Automotive | Essential for converting alternator power to DC for vehicle systems, especially in electric vehicles. |

Renewable Energy | Used in solar inverters to convert DC from solar panels to AC for grid use. |

Industrial Applications | Integral in power supply units for stable operation of machinery in manufacturing setups. |

Telecommunications | Ensures stable power for 5G base stations, enhancing service quality and minimizing downtime. |

Battery Charging Circuits

Battery charging circuits depend heavily on bridge rectifiers to provide controlled DC voltage. These circuits convert AC from the mains into a pulsating DC signal, which is then smoothed and regulated to charge batteries efficiently. This process is crucial for devices like smartphones, electric vehicles, and backup power systems.

The efficiency of bridge rectifiers in battery charging circuits stems from their ability to utilize the entire AC waveform. This design minimizes energy loss and ensures faster charging times. For instance:

A full-wave bridge rectifier with four low-loss diodes avoids energy elimination during each operation cycle.

Capacitive load energy storage improves energy extraction efficiency, directly impacting the circuit's overall performance.

However, selecting the right components is critical. Leakage currents in commercial rectifiers can lead to circuit failure, especially in low-power applications. Engineers must carefully evaluate the specifications of diodes and capacitors to ensure reliability and efficiency.

Note: Pairing a bridge rectifier with a voltage regulator and filter capacitor enhances the stability of the charging circuit, protecting batteries from overcharging or damage.

Industrial and Automotive Applications

Bridge rectifiers are indispensable in industrial and automotive settings, where reliability and efficiency are paramount. In industrial applications, they provide stable DC power for machinery, variable frequency drives (VFDs), and motor controllers. These rectifiers ensure uninterrupted operation, even in demanding environments.

In the automotive sector, bridge rectifiers convert AC generated by alternators into DC to charge vehicle batteries. This process powers essential systems like lighting, infotainment, and battery management. Electric and hybrid vehicles, in particular, rely on advanced rectifier circuits to manage their complex power requirements.

Recent advancements in materials like silicon carbide (SiC) and gallium nitride (GaN) have further improved the performance of bridge rectifiers in automotive applications. These materials enhance efficiency, reduce heat generation, and increase the reliability of power electronics. Key insights from industrial reports include:

Automotive bridge rectifiers are critical for electric and hybrid vehicles, ensuring stable power for battery management and distribution systems.

The transition to SiC and GaN materials has significantly improved the durability and efficiency of rectifiers in high-demand environments.

Tip: For industrial and automotive applications, selecting bridge rectifiers with high thermal tolerance and robust construction ensures long-term reliability.

LED Lighting and Consumer Electronics

Bridge rectifiers play a vital role in LED lighting systems and consumer electronics. These systems require a stable DC supply to operate efficiently, and rectifiers ensure this by converting AC input into a steady DC output. LEDs, which are sensitive to voltage fluctuations, benefit greatly from the consistent performance provided by bridge rectifiers.

Full-wave bridge rectifiers deliver a stable DC supply, preventing flickering in LED lights.

They improve the lifespan of LEDs by protecting them from voltage spikes and irregularities.

The rectifiers enhance energy efficiency, making LED lighting systems more reliable and cost-effective.

Consumer electronics also rely on rectifiers for smooth operation. Devices like televisions, radios, and smartphones depend on rectifiers to convert AC power into DC for their internal circuits. This conversion ensures uninterrupted performance and protects sensitive components from damage caused by power fluctuations.

Tip: When designing LED lighting systems, pairing a bridge rectifier with filtering components like capacitors can further reduce ripple voltage, ensuring optimal performance and durability.

Test Equipment and Laboratory Instruments

Test equipment and laboratory instruments require precise and stable DC power for accurate measurements and reliable operation. Bridge rectifiers are integral to these systems, as they provide the necessary DC supply by converting AC input. This ensures that sensors, meters, and other instruments function without interference from power fluctuations.

Laboratory instruments often include additional filtering components to refine the DC output. Capacitors and voltage regulators work alongside rectifiers to eliminate ripples and maintain a constant voltage level. This combination is essential for applications like spectroscopy, chromatography, and electrical testing, where even minor power variations can affect results.

In test equipment, bridge rectifiers support the operation of devices like oscilloscopes, signal generators, and multimeters. These tools require stable DC power to deliver accurate readings and consistent performance. Engineers and researchers rely on rectifiers to ensure the reliability of their equipment in demanding environments.

Note: Selecting a bridge rectifier with appropriate voltage and current ratings is crucial for test equipment and laboratory instruments. This prevents overheating and ensures long-term reliability.

Selecting the Right Bridge Rectifier

Voltage and Current Ratings

Choosing a bridge rectifier begins with understanding its voltage and current ratings. These parameters determine the rectifier's ability to handle the electrical load without failure. The voltage rating must exceed the peak input voltage to prevent breakdown, while the current rating should match or exceed the maximum load current. For instance, a rectifier designed for a 230V AC input should have a voltage rating of at least 325V (the peak value of the AC waveform). Similarly, the current rating should account for the load's requirements and any potential surges.

Tip: Always select a rectifier with a safety margin above the expected operating conditions to ensure long-term reliability.

Thermal and Environmental Considerations

Thermal performance and environmental resilience are critical for ensuring the durability of a bridge rectifier. High temperatures can degrade components, leading to reduced efficiency and eventual failure. Modern rectifiers incorporate features to address these challenges:

Reduced Junction Temperature: Lowering the junction temperature minimizes wear and extends the device's lifespan.

Lower Forward Voltage Drop: This reduces heat generation during operation.

Robust Die Attach Techniques: Enhanced bonding materials improve reliability under thermal cycling.

Applications like renewable energy systems, electric vehicles, and industrial power supplies demand rectifiers that can withstand extreme conditions. For example, rectifiers in solar inverters and wind turbine converters must operate efficiently in fluctuating temperatures. Similarly, automotive rectifiers handle high-current demands while resisting thermal stress.

Note: Devices qualified for harsh environments often feature hermetic construction and operate reliably between -65°C and +175°C.

Package Types and Mounting Options

Bridge rectifiers come in various package types and mounting options to suit different applications. Common package types include axial and surface-mount designs, which offer flexibility in circuit integration. Advanced options, such as epoxy-encapsulated and open-frame packages, provide higher power density and custom configurations.

Package Type | Description | Voltage Rating | Current Rating |

|---|---|---|---|

Epoxy Encapsulated | Rectifier assemblies (modules) | Up to 3kV | Up to 70A |

Open Frame | Higher power density assemblies (ISOPACs) | Custom | Custom |

For specialized applications, rectifiers may feature hermetic, non-cavity, double-plug construction. These designs are ideal for space-grade and military-grade systems, offering enhanced durability and performance. Engineers can also select rectifiers with custom screening and processing capabilities to meet specific requirements.

Tip: When selecting a package type, consider factors like thermal dissipation, mounting space, and environmental conditions.

Cost vs. Performance Factors

Selecting the right bridge rectifier involves balancing cost and performance. Engineers and designers must evaluate the specific requirements of their applications to make informed decisions. While cost is a significant factor, prioritizing performance ensures long-term reliability and efficiency.

Several factors influence the cost of a rectifier. The type of materials used, such as silicon or advanced compounds like silicon carbide (SiC), plays a major role. SiC-based rectifiers, for example, offer higher efficiency and thermal performance but come at a premium price. Similarly, the manufacturing process and additional features, such as hermetic sealing or enhanced thermal management, can increase costs.

Performance, on the other hand, depends on parameters like voltage and current ratings, thermal tolerance, and ripple reduction capabilities. High-performance rectifiers often feature lower forward voltage drops, which reduce energy loss and heat generation. These characteristics make them ideal for demanding applications, such as industrial motor drives or automotive systems.

Tip: For cost-sensitive projects, standard silicon-based rectifiers provide a reliable and economical solution. However, high-performance applications may justify the investment in advanced materials like SiC.

The choice between cost and performance also depends on the operating environment. Applications exposed to extreme temperatures or high currents may require robust and durable rectifiers, even if they are more expensive. Conversely, low-power consumer electronics can often use cost-effective options without compromising functionality.

A careful analysis of the application's needs ensures the right balance between cost and performance. This approach minimizes unnecessary expenses while maintaining the desired level of efficiency and reliability.

Bridge rectifiers play a pivotal role in modern electronics by converting AC to DC power efficiently. Their versatility allows them to function across various industries, from consumer electronics to industrial machinery. The table below highlights key factors driving their demand:

Factor Driving Demand | Description |

|---|---|

Consumer Electronics | Exponential rise in consumption of smartphones, tablets, and laptops increases the need for efficient power conversion. |

Electric Vehicles | Shift towards EVs creates a surge in demand for efficient power management solutions. |

Versatility | Usable in both single-phase and three-phase configurations across various industries, from household appliances to industrial machines. |

Selecting the right bridge rectifier ensures optimal performance and reliability. Engineers should evaluate voltage, current ratings, and environmental conditions to match specific application needs.

What is the main purpose of a bridge rectifier?

A bridge rectifier converts alternating current (AC) into direct current (DC). This process provides a stable DC output, which is essential for powering electronic devices, charging batteries, and operating industrial equipment.

How do I choose the right bridge rectifier for my application?

Consider the voltage and current ratings of the rectifier. Ensure the voltage rating exceeds the peak input voltage and the current rating matches or exceeds the load requirements. Evaluate thermal performance and environmental conditions for long-term reliability.

Why are four diodes used in a bridge rectifier?

The four diodes form a bridge configuration. This design allows current to flow in one direction through the load during both halves of the AC cycle. It ensures efficient rectification and maximizes the use of the AC waveform.

Can a bridge rectifier work without a filter capacitor?

Yes, but the output will be a pulsating DC signal with ripples. Adding a filter capacitor smooths the output, reducing fluctuations and providing a more stable DC voltage for sensitive applications.

What are the advantages of bridge rectifiers over half-wave rectifiers?

Bridge rectifiers utilize both halves of the AC waveform, resulting in higher efficiency and a smoother DC output. They also produce a lower ripple factor, making them more suitable for applications requiring stable power.

See Also

Understanding The IRF820 N-Channel MOSFET For Power Applications

Reasons To Select Coilcraft XPL2010 For VRM And VRD

Comprehensive Guide To Using AD620AN In Television Power

CALL US DIRECTLY

(+86)755-82724686

RM2508,BlockA,JiaheHuaqiangBuilding,ShenNanMiddleRd,Futian District,Shenzhen,518031,CN

www.keepboomingtech.com sales@keepboomingtech.com