How to Use BTA16-800B Triac in AC Circuits

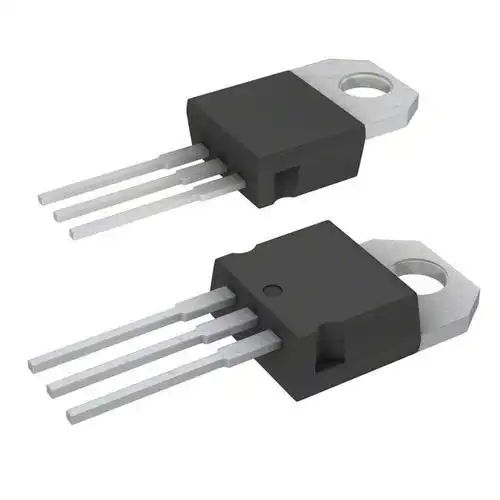

The BTA16-800B BTA16-800 Triac is a versatile integrated circuit chip designed for efficient control of AC circuits, serving as a dependable electronic switch. This BTA16 medium current triac thyristor operates through phase control, enabling precise regulation of power flow in various electrical systems. Widely utilized in general-purpose AC switching applications, it is ideal for light dimmers, motor controllers, and other similar uses. Its compatibility with simple triac switch circuits makes it a crucial component in integrated circuit chip designs. Ensuring proper connection and adhering to safety practices are essential for achieving optimal performance and preventing operational damage.

Key Takeaways

The BTA16-800B Triac is a dependable switch for AC circuits. It works well in things like light dimmers and motor controllers.

To set it up, you need parts like resistors, diodes, and heat sinks. These help it work safely and efficiently.

Microcontrollers can make the triac easier to control. They let you adjust things like motor speed more precisely.

Always follow safety rules. Handle high voltage with care and use heat sinks to keep the triac cool. This protects both the device and the user.

The triac is very useful. It works in many things, from home gadgets to factory machines, and helps save energy.

Key Features of the BTA16-800B Triac

Electrical Specifications of the BTA16-800B

The BTA16-800B Triac is designed to handle medium current loads in alternating current (AC) circuits. Its electrical specifications make it suitable for a wide range of applications. Below is a summary of its key parameters:

Parameter | Value |

|---|---|

Voltage Rating (VDRM, VRRM) | 800V |

RMS Current (IRMS) | 16A |

Gate Trigger Voltage (VGT) | 1.3V (max) |

Gate Trigger Current (IGT) | 50mA (max) |

Hold Current (IH) | 50mA |

Surge Current (ITSM) | 160A, 168A |

Leakage Current | 2mA (max) |

Critical Rate of Rise of Voltage | 400V/µs |

These specifications highlight the triac's ability to manage high voltages and currents while maintaining reliable operation. Its insulated package enhances thermal performance and safety, making it ideal for general-purpose AC switching.

How the BTA16 Medium Current Triac Thyristor Operates

The BTA16-800B operates as a bidirectional thyristor, allowing current to flow in both directions when triggered. It uses a gate terminal to control the flow of current through the main terminals (MT1 and MT2). This triac excels in phase control circuits, where it adjusts the power delivered to a load by controlling the conduction angle of the AC waveform.

Key operational features include:

Snubberless Technology: Eliminates the need for external snubber circuits, simplifying design.

Noise Immunity: Ensures stable performance in environments with electrical noise.

Thermal Management: Advanced clip bonding improves heat dissipation, ensuring durability.

Enhanced di/dt Capabilities: Handles rapid changes in current effectively, reducing the risk of failure.

These features make the BTA16-800B a reliable choice for applications like light dimming, motor speed regulation, and heating control.

Benefits of Using the BTA16-800B in AC Circuits

The BTA16-800B offers several advantages for AC circuit applications:

Versatility: Supports a wide range of uses, including light dimmers, motor controllers, and solid-state relays.

Efficiency: Reduces energy loss through precise phase control, improving overall system performance.

Compact Design: The TO-220AB package with an insulated tab ensures easy integration into compact designs.

Reliability: With robust thermal and electrical characteristics, it performs consistently under varying conditions.

Cost-Effectiveness: Simplifies circuit design by eliminating the need for additional components like snubbers.

These benefits make the BTA16-800B an essential component for engineers working on general-purpose AC switching and phase control circuits.

Connecting the BTA16-800B Triac in AC Circuits

Components and Tools Needed for Setup

Setting up the BTA16-800B triac requires a few essential components and tools. These items ensure proper assembly and functionality of the circuit. Below is a list of what is needed:

BTA16-800B Triac: The main component for controlling AC power.

Resistors: Used to limit current and protect the gate terminal.

Diodes: Provide protection against voltage spikes.

Capacitors: Help stabilize the circuit and reduce noise.

Heat Sink: Ensures proper heat dissipation for the triac.

AC Load: Such as a lamp, motor, or heater, to test the circuit.

Breadboard or PCB: For assembling the components.

Wires and Connectors: Facilitate connections between components.

Multimeter: Measures voltage, current, and resistance for testing.

Screwdriver and Soldering Iron: For assembling and securing the components.

Having these tools and components ready simplifies the setup process and ensures a smooth assembly of the triac circuits.

Step-by-Step Wiring Instructions

Connecting the BTA16-800B triac in a circuit involves a systematic approach. Follow these steps to wire the triac correctly:

Identify the Terminals: Locate the Main Terminal 1 (MT1), Main Terminal 2 (MT2), and Gate (G) on the BTA16-800B. Refer to the datasheet for clarity.

Prepare the Circuit Board: Place the triac on a breadboard or solder it onto a PCB. Ensure the terminals are accessible for connections.

Connect the Load: Attach one end of the AC load (e.g., a lamp or motor) to MT2. The other end connects to the AC power supply.

Add a Resistor to the Gate: Connect a resistor between the gate terminal and the control signal source. This resistor limits the current flowing into the gate.

Include a Diode and Capacitor: Place a diode across the load to protect against voltage spikes. Add a capacitor near the triac to reduce noise and stabilize the circuit.

Attach the Heat Sink: Secure a heat sink to the triac to manage heat dissipation during operation.

Connect the Power Supply: Attach the AC power supply to MT1 and the other end of the load. Double-check all connections for accuracy.

These steps ensure the BTA16-800B triac is correctly wired for safe and efficient operation in AC circuits.

Testing and Verifying the Circuit

Testing the circuit is crucial to ensure it functions as intended. Follow these steps to verify the setup:

Inspect the Connections: Check all connections for accuracy and ensure there are no loose wires.

Measure Resistance: Use a multimeter to measure the resistance between MT1 and MT2. The reading should be high when the gate is not triggered.

Apply a Control Signal: Provide a control signal to the gate terminal. This signal can come from a microcontroller or a simple switch.

Observe the Load: When the gate is triggered, the load (e.g., a lamp or motor) should activate. If it does not, recheck the wiring and components.

Monitor Heat Levels: During operation, monitor the heat sink to ensure it effectively dissipates heat.

Test Different Loads: Test the circuit with various AC loads to confirm its versatility and reliability.

By following these steps, users can confirm that the BTA16-800B triac operates correctly and safely in their triac circuits.

Controlling the BTA16-800B Triac

Gate Triggering Techniques

The gate terminal plays a crucial role in activating the BTA16-800B triac. Triggering the gate allows current to flow between the main terminals, enabling the triac to function as a switch in AC circuits. Several techniques ensure reliable gate activation.

Resistor-Based Triggering: A resistor connected to the gate limits the current, preventing damage to the thyristor. This method is simple and effective for basic triac circuits.

DIAC Integration: Adding a DIAC (Diode for Alternating Current) to the triggering circuit stabilizes the firing points. This improves switching cycle symmetry and reduces harmonic distortion.

Pulse Triggering: Short-duration pulses applied to the gate ensure precise activation. This technique minimizes power loss and enhances control accuracy.

These methods optimize gate triggering, ensuring the triac operates efficiently without risking triac failure analysis due to improper activation.

Using Microcontrollers for Precise Control

Microcontrollers provide advanced control capabilities for the BTA16-800B triac. They generate precise signals to trigger the gate, enabling accurate phase control in AC circuits.

PWM (Pulse Width Modulation): Microcontrollers use PWM signals to adjust the conduction angle of the triac. This technique allows fine-tuned control over the power delivered to the load.

Zero-Crossing Detection: Microcontrollers can detect the zero-crossing point of the AC waveform. Triggering the triac at this point reduces electrical noise and improves efficiency.

Programmable Logic: Microcontrollers enable dynamic adjustments based on real-time data. For example, temperature sensors can regulate heating elements by modifying the triac's conduction angle.

Using microcontrollers enhances the versatility of triac circuits, making them suitable for applications like motor speed regulation and light dimming.

Common Control Configurations for the Triac

Effective control configurations ensure the BTA16-800B triac operates reliably in various applications. Engineers often implement specific designs to manage voltage surges, stabilize firing points, and maintain circuit integrity.

Snubber Circuits: These circuits protect the triac from voltage spikes. They consist of resistors and capacitors that absorb transient energy, preventing triac failure analysis due to overvoltage.

Capacitance Discharge Control: Resistors connected to capacitors regulate discharge rates, maintaining circuit stability during operation.

Zero-Crossing Techniques: Triggering the triac at the zero-crossing point minimizes electrical noise and ensures smooth AC voltage management.

Gate Drive Circuitry: Proper gate drive design ensures consistent triggering under varying conditions. This reduces the risk of triac failure and enhances overall reliability.

DIAC Usage: Incorporating DIACs in the gate circuit improves switching cycle symmetry and reduces harmonic distortion.

These configurations optimize the performance of the BTA16-800B triac, ensuring it functions effectively in diverse AC switching applications.

Applications of the BTA16-800B Triac

Light Dimming and Fan Speed Regulation

The BTA16-800B triac is widely used in light dimmers and fan speed controllers due to its ability to regulate power flow efficiently. By adjusting the conduction angle of the AC waveform, this thyristor enables precise control over the brightness of lights or the speed of fans. A typical dimmer circuit includes components such as a resistor, capacitor, diac, and the triac itself. Each component plays a critical role in ensuring smooth operation.

Component | Description |

|---|---|

Supplies 230V, 50Hz AC power to the circuit. | |

Resistor (R1) | Controls the charging time of the capacitor. |

Diac (DB3) | Triggers the triac when the voltage threshold is reached. |

Triac (BTA16-800) | Controls the power delivery to the load. |

Load (Light Bulb) | The device being dimmed or controlled. |

This configuration allows dimmer switches to operate efficiently, providing a cost-effective solution for residential and commercial applications.

Motor Control in Household and Industrial Settings

The BTA16-800B triac excels in motor speed controllers for both household and industrial environments. Its ability to handle inductive and resistive loads makes it a versatile choice for various motor control applications. In household settings, it is commonly used in washing machines and vacuum cleaners. In industrial environments, it supports compressor starting and motor control systems.

Application Type | Examples of Use | Performance Benefits |

|---|---|---|

Household | Reliable control for resistive loads | |

Industrial | Compressor starting, motor controls | Effective for inductive loads, smooth operation |

This thyristor ensures smooth motor operation by regulating the power supplied to the motor, reducing wear and tear while improving efficiency.

Power Regulation in Heating and Solid-State Relays

The BTA16-800B triac is a key component in power regulation for heating systems and solid-state relays. It provides precise control over heating elements in devices like electric ovens and water heaters. By adjusting the power delivered to the heating element, it maintains consistent temperatures, enhancing energy efficiency.

In solid-state relays, the triac replaces mechanical switches, offering silent and fast switching. This feature is particularly beneficial in industrial automation, where reliability and speed are critical. The triac's ability to handle high currents and voltages ensures dependable performance in demanding applications.

Safety Precautions for Using the BTA16-800B Triac

Managing High Voltage Safely

High voltage poses risks to both users and components in a circuit. Proper handling ensures safety during operation. Users should always disconnect the power supply before assembling or modifying the circuit. Insulated tools reduce the risk of accidental contact with live wires. Protective gloves and goggles shield users from electrical hazards.

The triac must be installed in a secure enclosure to prevent accidental exposure to high voltage. Labels indicating "High Voltage" warn others of potential dangers. Regular inspections of wires and connections help identify wear or damage that could lead to short circuits.

Tip: Use a multimeter to verify voltage levels before powering the circuit. This precaution minimizes the risk of electrical shock.

Protecting the Triac from Overvoltage and Overcurrent

Overvoltage and overcurrent can damage the triac and compromise circuit performance. Surge protection devices, such as varistors, absorb excess voltage during power spikes. Fuses or circuit breakers interrupt the current flow when it exceeds safe limits.

A snubber circuit, consisting of a resistor and capacitor, protects the triac from voltage transients. This configuration reduces stress on the component and extends its lifespan. Engineers should select components rated for the maximum voltage and current expected in the application.

Note: Always test the circuit under controlled conditions to ensure the triac operates within its specified limits.

Ensuring Proper Heat Dissipation with Heatsinks

Heat dissipation is critical for maintaining the triac's reliability. Prolonged operation generates heat, which can degrade performance or cause failure. A heatsink attached to the triac dissipates excess heat efficiently. The heatsink should have a flat surface and be securely mounted to ensure optimal thermal contact.

Thermal paste improves heat transfer between the triac and heatsink. Adequate ventilation around the heatsink prevents heat buildup. For high-power applications, forced cooling with fans enhances heat dissipation.

Tip: Monitor the heatsink temperature during operation. If it becomes excessively hot, consider upgrading to a larger heatsink or adding active cooling.

Using the BTA16-800B triac in AC circuits requires careful attention to setup, control, and safety. Following the outlined steps ensures proper wiring, reliable operation, and effective testing. Understanding the triac's specifications helps users select the right components for their circuit. Adhering to safety measures, such as managing high voltage and ensuring heat dissipation, protects both the device and the user.

This triac offers versatility across various applications, from light dimming to motor control. By exploring its potential and following best practices, engineers and hobbyists can achieve efficient and reliable results in their projects.

FAQ

What is the primary application of the BTA16-800B triac?

The BTA16-800B triac is primarily used in AC switching and phase control applications. Common uses include light dimming, motor speed regulation, and power control in heating systems. Its versatility makes it suitable for both household and industrial settings.

How does the triac handle high voltage safely?

The triac uses an insulated package and requires proper circuit design with components like snubber circuits and varistors. These elements protect the device from voltage spikes and ensure safe operation in high-voltage environments.

Can microcontrollers control the BTA16-800B triac?

Microcontrollers can precisely control the triac by generating PWM signals and detecting zero-crossing points. This enables accurate phase control, making the triac ideal for applications requiring dynamic adjustments.

What precautions should be taken during installation?

Users should disconnect the power supply before installation. Insulated tools and protective gear minimize risks. Proper heat dissipation with heatsinks and secure enclosures ensure safe and reliable operation.

Is the BTA16-800B suitable for solid-state relays?

Yes, the triac is ideal for solid-state relays. It replaces mechanical switches, offering silent and fast switching. This makes it a reliable choice for industrial automation and high-power applications.

See Also

Integrating ATA5824C Into Your Remote Control Solutions

Three Key Benefits of ATIC83E2 for Industrial Automation

Comprehensive Guide to Using AD620AN in TV Power

Enhancing Process Control with AD74413RBCPZ Insights

ARTESYN NPT42-M: Energizing the Future of Industrial Automation

CALL US DIRECTLY

(+86)755-82724686

RM2508,BlockA,JiaheHuaqiangBuilding,ShenNanMiddleRd,Futian District,Shenzhen,518031,CN

www.keepboomingtech.com sales@keepboomingtech.com