Engineers carefully select Ceramic Capacitor components for industrial environments. They consider key specifications. These include capacitance, voltage rating, temperature coefficient (TC), equivalent series resistance (ESR), equivalent series inductance (ESL), insulation resistance (IR), dielectric material, and package size. These specifications directly impact a capacitor’s reliability and stability. This ensures optimal performance and longevity in demanding applications.

Key Takeaways

-

Engineers choose ceramic capacitors for industrial use. They look at things like how much charge they store and how much voltage they can handle. This helps make sure machines work well and last a long time.

-

Capacitors need to work well even when temperatures change a lot. Different materials help them stay stable. This keeps circuits working correctly.

-

Low ESR and ESL are important for capacitors. Low ESR means less power is wasted as heat. Low ESL helps block unwanted signals. This makes industrial electronics run better.

-

Capacitors must be strong. They need to handle bumps and shakes. They also need to be tested to strict standards. This ensures they are reliable in tough industrial places.

1. Capacitance and Voltage Rating for Ceramic Capacitors

1.1. Capacitance Value: Charge Storage

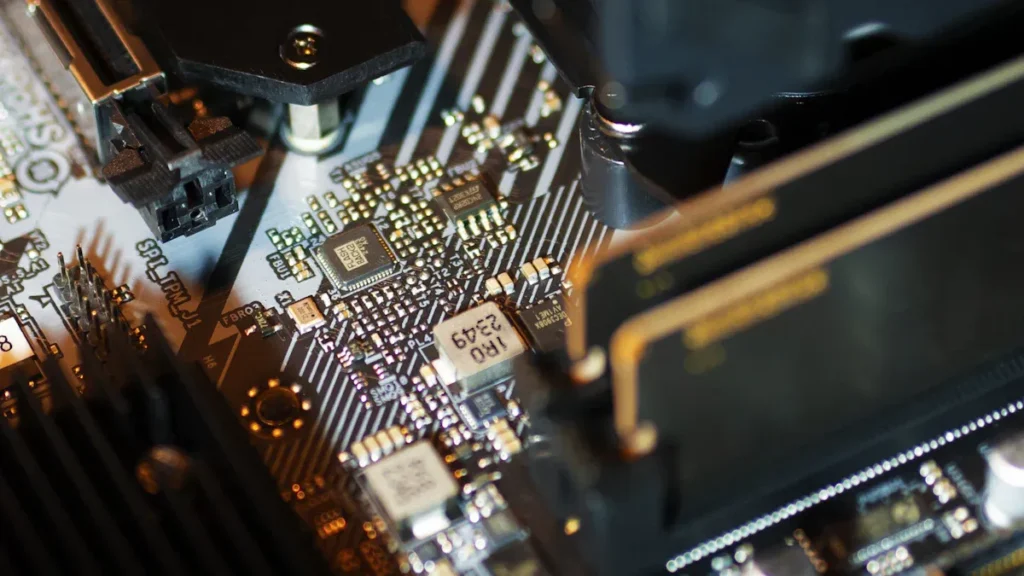

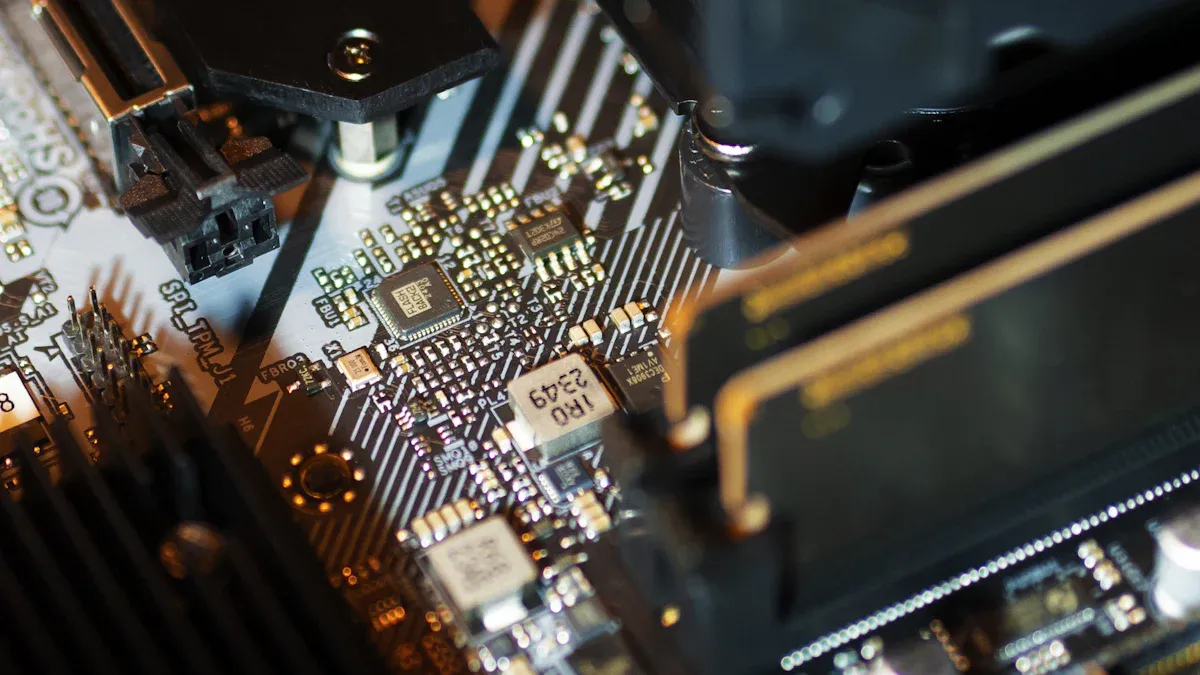

Capacitance is a fundamental property. It defines a component’s ability to store an electrical charge. For industrial applications, the capacitance value directly impacts energy storage and filtering needs. For example, engineers use capacitors to decouple microcontrollers (MCUs). This removes high-frequency noise from power lines. They also smooth power in switching mode power supplies (SMPS). A Ceramic Capacitor provides stable power delivery. This ensures reliable operation of sensitive industrial electronics. Proper capacitance selection prevents voltage drops and maintains signal integrity.

1.2. Voltage Rating: Preventing Breakdown

The voltage rating specifies the maximum voltage a capacitor can safely withstand. Exceeding this limit causes dielectric breakdown. This leads to permanent damage or failure. In high-stress industrial applications, such as power converters, a robust voltage rating is crucial. These systems often experience voltage spikes or transients. A capacitor with an insufficient voltage rating will fail prematurely. Engineers must select capacitors with a rating well above the expected operating voltage. This provides a safety margin.

1.3. Derating for Lifespan

Derating is a common practice. It involves operating a component below its nominal specifications. For capacitors, this means applying less than the maximum rated voltage. This practice significantly extends the component’s lifespan and improves reliability. A typical derating guideline suggests applying only 50-70% of the nominal voltage. This is especially important for high-voltage systems. For instance, electric vehicle (EV) power systems operate at 250V-400V. Derating ensures the capacitors withstand continuous stress. It also accounts for environmental factors like temperature fluctuations. This proactive approach prevents unexpected failures in critical industrial equipment.

2. Temperature Stability and Dielectric Material

2.1. Temperature Coefficient (TC): How Temperature Affects Capacitance

Temperature significantly influences a capacitor’s performance. The Temperature Coefficient (TC) describes how capacitance changes with temperature. Industrial environments often experience wide temperature fluctuations. A stable TC ensures the capacitor maintains its specified capacitance value. This consistency is vital for reliable circuit operation. Engineers select capacitors with low TC values for applications requiring precise timing or filtering. This prevents performance drift due to heat or cold.

2.2. Dielectric Types for Temperature Stability

Different dielectric materials offer varying levels of temperature stability. C0G/NP0 dielectrics provide extremely stable capacitance. They show minimal change across a broad temperature range. Engineers use them in precision circuits like RF applications or timing circuits. X7R dielectrics are general-purpose. They offer good stability for many industrial uses. Y5V dielectrics provide high capacitance in a small size. However, their capacitance changes significantly with temperature. Designers choose Y5V for less critical applications where space is limited.

2.3. Class I vs. Class II Dielectrics

Dielectrics fall into two main classes. Class I dielectrics, such as C0G/NP0, offer high stability. They have a linear temperature response and low losses. However, they typically provide lower capacitance values. Class II dielectrics, including X7R and Y5V, offer higher capacitance. They achieve this in smaller packages. These materials are less stable. Their capacitance changes more with temperature and applied voltage. Engineers weigh stability against volumetric efficiency when selecting between these classes. A Ceramic Capacitor with a Class I dielectric suits high-precision needs.

2.4. Impact on Aging and DC Bias Characteristics

The dielectric material choice also affects a capacitor’s aging characteristics. Some materials experience a gradual decrease in capacitance over time. This is called aging. Additionally, applying a DC voltage (DC bias) can reduce the effective capacitance, especially in Class II dielectrics. This effect is more pronounced in higher capacitance values and smaller case sizes. Engineers must consider these factors. They ensure the capacitor maintains its required performance throughout the product’s lifespan. This attention to detail is crucial for long-term reliability in industrial systems.

3. ESR, ESL, and IR: Minimizing Losses and Ensuring Integrity

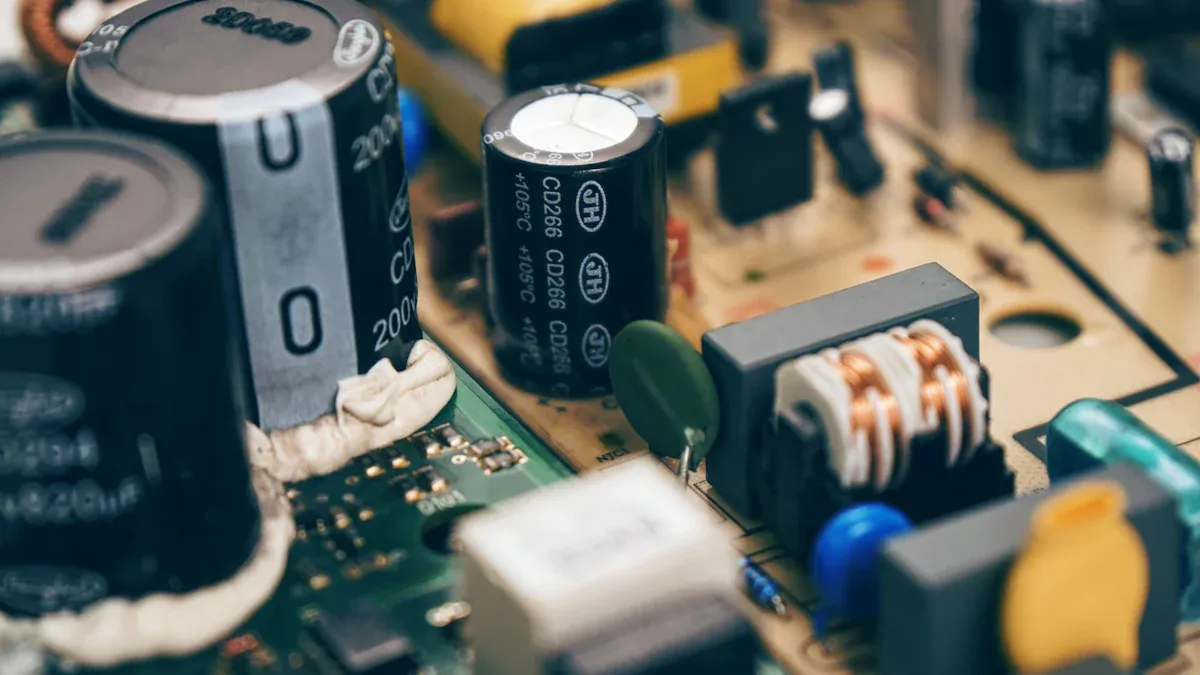

3.1. ESR: Managing Power Dissipation

Equivalent Series Resistance (ESR) represents the total resistance within a capacitor. This resistance includes the dielectric, plate, and lead resistances. A low ESR is crucial for efficient operation. High ESR causes power loss. It also generates unnecessary heat within the component. This directly increases power dissipation and temperature rise. Engineers select capacitors with low ESR values. This minimizes energy waste and prevents overheating in industrial circuits.

3.2. ESL: Mitigating High-Frequency Noise

Equivalent Series Inductance (ESL) is the parasitic inductance present in a capacitor. While small, ESL becomes significant at high frequencies. It can limit a capacitor’s effectiveness in filtering high-frequency noise. High ESL can cause resonance issues. This reduces the capacitor’s ability to bypass unwanted signals. For high-speed industrial applications, such as RF circuits or fast switching power supplies, low ESL is essential. It ensures effective noise suppression and stable circuit performance.

3.3. IR: Minimizing Leakage Current

Insulation Resistance (IR) measures how well a capacitor’s dielectric material resists DC current flow. A high IR value indicates very low leakage current. Leakage current is a small amount of current that flows through the dielectric even when the capacitor is fully charged. Minimizing leakage current is vital for power efficiency. Leakage current significantly impacts the power consumption of battery-powered industrial devices. It reduces battery life. For example, the Texas Instruments TPSM82816 module reduces leakage current. This improves battery life in industrial applications. Lower current demand during standby modes prolongs device longevity.

3.4. Dielectric Strength: Withstanding Overvoltages

Dielectric strength refers to the maximum electric field a dielectric material can withstand without breaking down. This specification is critical for capacitor reliability. It ensures the capacitor can handle transient overvoltages or voltage spikes. Industrial environments often experience such electrical disturbances. A Ceramic Capacitor with high dielectric strength provides robust protection. It prevents catastrophic failure and ensures the long-term integrity of the electronic system.

4. Physical Attributes and Qualification for Robustness

4.1. Package Size and Mounting: Physical Integration

Capacitor package size directly influences board space availability. Industrial designs often demand compact solutions. Smaller packages save valuable real estate on circuit boards. However, larger packages sometimes offer better power handling capabilities or higher voltage ratings. Engineers must balance these factors. The physical dimensions of a Ceramic Capacitor must integrate seamlessly into the overall system design. Proper integration prevents mechanical stress and ensures efficient component placement.

4.2. Mounting Type: Vibration and Assembly

The chosen mounting type significantly impacts a capacitor’s resilience against mechanical stress. Surface Mount Technology (SMT) components are widely used. They offer good vibration resistance when properly soldered to the PCB. Through-hole components provide a stronger mechanical attachment. This makes them suitable for applications with extreme vibration or shock. Industrial environments frequently expose electronics to harsh mechanical forces. A robust mounting method prevents component detachment. It also maintains electrical connections during operation. Careful consideration of assembly processes further enhances reliability.

4.3. Thermal Dissipation: Preventing Overheating

Capacitors generate heat internally during operation. This heat comes from equivalent series resistance (ESR) losses. Effective thermal dissipation is critical. It prevents the component from overheating. Overheating accelerates degradation. It significantly reduces the capacitor’s lifespan. Larger package sizes generally dissipate heat more effectively due to a larger surface area. The surrounding board layout also influences heat transfer. Engineers design for adequate airflow. They consider thermal pathways to prevent hot spots. This proactive thermal management ensures sustained performance and longevity in demanding industrial settings.

4.4. Reliability Standards and Qualifications

Industrial applications demand components with proven reliability. Manufacturers qualify components through rigorous testing. These tests ensure robustness under harsh conditions. Common qualification tests include temperature cycling. They also involve humidity exposure, mechanical shock, and vibration tests. Standards like AEC-Q200, originally developed for the automotive industry, often apply to industrial electronics. Components passing these stringent qualifications demonstrate their ability to perform reliably. They withstand extreme environmental stresses. This rigorous testing guarantees component integrity and long-term operational stability.

Selecting a Ceramic Capacitor for industrial environments demands careful consideration of capacitance, voltage rating, temperature coefficient, ESR, ESL, insulation resistance, dielectric material, and package size. Prioritizing these specifications ensures optimal reliability and stability. These factors are crucial for the longevity and performance of industrial electronic systems. By understanding and applying these key parameters, engineers design robust and dependable solutions. These solutions withstand the rigors of harsh industrial conditions. 🛠️

FAQ

What makes C0G/NP0 dielectrics suitable for industrial use?

C0G/NP0 dielectrics offer exceptional temperature stability. Their capacitance changes minimally across wide temperature ranges. This makes them ideal for precision circuits. They ensure consistent performance in demanding industrial environments.

Why is derating voltage important for ceramic capacitors?

Derating voltage extends a capacitor’s lifespan. It involves operating the capacitor below its maximum rated voltage. This practice provides a safety margin. It prevents premature failure, especially in high-stress industrial applications.

How do ESR and ESL impact capacitor performance in industrial systems?

ESR (Equivalent Series Resistance) causes power loss and heat generation. ESL (Equivalent Series Inductance) limits high-frequency filtering effectiveness. Low ESR and ESL are crucial. They ensure efficient operation and stable noise suppression in industrial electronics.

What are AEC-Q200 qualifications for ceramic capacitors?

AEC-Q200 is an automotive industry standard. It ensures component reliability under harsh conditions. Capacitors passing these tests demonstrate robustness. They withstand extreme temperatures, vibrations, and humidity. This makes them suitable for industrial applications.

Why does dielectric material affect a capacitor’s aging characteristics?

Different dielectric materials age differently. Some materials experience a gradual capacitance decrease over time. DC bias can also reduce effective capacitance. Engineers consider these factors. They ensure long-term reliability in industrial systems.

See Also

Achieving Excellence: Innovation, Quality, and Future Trends in Electronic Components

Coilcraft XPL2010: High-Performance Inductors for Advanced VRM/VRD Designs

SPC56 Microcontrollers: Mastering Automotive Powertrains Through Advanced Engine Core Applications

ARTESYN NPT42-M: Essential Power Solutions for Industrial Automation Systems

M30280FAHP Microcontroller: Core Performance and Compliance in Medical Electronics