Microcontrollers, or MCUs used in humanoid robots, function like the brain of these machines. They control movements and dictate how robots interact with their surroundings. Choosing the right MCU requires careful consideration of performance, compatibility, and cost. Numbers help compare these factors and simplify decision-making. Strong MCUs allow for accurate movement, seamless sensor integration, and quick responses. Compatibility ensures smooth connections with other components. Cost is a crucial factor in building robots without overspending, and saving money is increasingly important in robot research. The MCUs used in humanoid robots enable new capabilities, merging technology and practicality in innovative ways.

Key Takeaways

-

Microcontrollers (MCUs) are like the brain of robots. They control how robots move and interact with their surroundings.

-

When picking an MCU, think about its speed, how well it works with other parts, and its price. This helps the robot work better.

-

MCUs with good input/output (I/O) features connect easily to sensors and motors. This makes the robot work smarter.

-

Power-saving MCUs help robots use less battery. This lets them run longer without needing to recharge often.

-

Choose an MCU that can be upgraded later. This way, you can add new features without replacing the whole thing.

Understanding MCUs Used in Humanoid Robots

What is a Microcontroller?

A microcontroller is a small chip made for specific tasks. It works like the brain of devices, including humanoid robots. It has a processor, memory, and input/output (I/O) parts all on one chip. This makes it great for controlling robot actions.

Microcontrollers use two main designs: Von Neumann or Harvard. The table below shows how they differ:

|

Feature/Aspect |

Von Neumann Architecture |

Harvard Architecture |

|---|---|---|

|

Data Handling |

One bus for data and instructions |

Separate buses for data and instructions |

|

Performance |

Slower performance |

Faster due to simultaneous transfers |

|

Processor Types |

4-bit to 64-bit options |

4-bit to 64-bit options |

|

Memory Types |

RAM, Flash, ROM |

RAM, Flash, ROM |

|

Instruction Set |

Complex Instruction Set (CISC) |

Reduced Instruction Set (RISC) |

|

Number of Instructions |

About 80 instructions |

About 30 instructions |

|

Addressing Modes |

12 to 24 modes |

3 to 5 modes |

|

Assembly, C, Python, JavaScript |

Assembly, C, Python, JavaScript |

|

|

Peripheral Functions |

ADCs, LCDs, clocks, USB |

ADCs, LCDs, clocks, USB |

This flexibility makes microcontrollers very useful in robots.

Role of MCUs in Humanoid Robotics

MCUs in humanoid robots handle many important tasks. They read sensor data, move motors, and connect parts. For example, if a robot sees an obstacle, the MCU reads the sensor data and changes its path. This helps the robot move smartly.

Microcontrollers also let robots do hard tasks like understanding voices or gestures. These features help robots interact better with people.

Why MCUs Are Essential for Robotics Applications

Microcontrollers are key because they control robot parts precisely. For instance, a study showed how an MCU controlled robotic arms with great accuracy. This proves how important MCUs are for smooth movements and part connections.

In humanoid robots, MCUs make quick decisions and save power. They also support AI, helping robots learn and improve. Without MCUs, humanoid robots wouldn’t be as advanced as they are today.

Key Things to Think About When Picking a Microcontroller for Robots

Processing Power and Performance

Processing power shows how well a microcontroller works. Robots need strong MCUs to handle sensors, motors, and tasks quickly. For example, a robot walking or picking things up needs a fast MCU. A quick clock speed and many cores help it do many tasks at once.

Bluetooth 5 shows how processing power helps robots talk to each other. It has cool features like:

-

Timing events from 7.5 ms to 4 seconds.

-

A 24-bit CRC to find errors in data.

-

Flow control to stop losing data packets.

-

LE 2 M PHY for faster speed and saving power.

-

LE Coded PHY for longer range without more power.

These features show why strong processing power is important for robots to work well and talk smoothly.

I/O Features for Adding Parts

Input/output (I/O) features help connect sensors, motors, and other parts. A microcontroller with good I/O setups moves data easily between parts. For example, a robot with sensors for seeing, touching, and hearing needs an MCU that handles many I/O connections.

Here’s how I/O setups help connect parts:

-

The device asks to use the bus.

-

Data moves at the device’s speed, slower than the CPU.

-

The CPU gets the bus back after the transfer.

-

The device saves the data in memory.

-

The CPU gets a message about the data.

-

Data moves at the system bus speed.

-

The CPU gets the bus back again.

Good I/O handling stops delays and makes parts work well together. This is very important for robots.

Ways to Connect (Wi-Fi, Bluetooth, CAN bus)

Connections help robots talk to other systems. Wi-Fi, Bluetooth, and CAN bus are common choices. Each has its own benefits. The table below compares them:

|

Technology |

Range |

Power Use |

Data Speed |

Uses |

|---|---|---|---|---|

|

Wi-Fi |

Short |

Medium |

High |

Smart homes, smart gadgets |

|

Bluetooth |

~200m (Bluetooth) to 700m (BLE) |

35 mA (BLE) to 100 mA |

350 Kbps (Bluetooth) to 3 Mbps (BLE) |

Consumer gadgets, industrial devices |

|

CAN bus |

Up to 40m |

Low |

1 Mbps |

Cars, factory robots |

Wi-Fi is fast and good for sending lots of data. Bluetooth balances range and power, great for gadgets and factories. CAN bus uses little power and works well for short distances, like in cars. Picking the right connection depends on what the robot needs and where it works.

Memory Needs (RAM and Flash Storage)

Memory is very important for how well a microcontroller works. RAM (Random Access Memory) and flash storage decide how much data it can handle. RAM deals with temporary data like sensor readings and calculations. Flash storage keeps permanent data, such as programs and control rules.

Humanoid robots need enough RAM for real-time tasks. For example, reading sensors, moving motors, and running AI need a lot of memory. If the RAM is too small, the robot may slow down or stop working. Flash storage is also needed for saving big programs and updates. Robots with features like voice or gesture control need more flash storage.

When picking a microcontroller, developers should check the robot’s memory needs. A simple robot may need less memory. A robot with advanced AI will need more. Balancing RAM and flash storage helps the robot work well and allows future updates.

Power Saving for Mobile Robots

Mobile robots need to save power because they use batteries. A microcontroller that uses less power makes the battery last longer. This lets the robot work longer without charging. Saving power also reduces heat, which helps the robot perform better.

Studies show why power saving is important for mobile robots. The table below explains key points:

|

Key Point |

What It Means |

|---|---|

|

Batteries power mobile robots |

Shows why battery life matters |

|

Moving uses over 50% of energy |

Better control saves energy |

|

Path planning saves energy |

Good algorithms help batteries last |

Low-power microcontrollers have features like sleep modes and voltage control. These save energy when the robot is idle or working lightly. Developers should choose microcontrollers with these features to make batteries last longer.

Growing for Future Needs

Scalability means a robot can grow with new technology. A scalable microcontroller lets developers add features or improve old ones without replacing it. This keeps robots updated with new tools.

Research on scalability gives useful ideas. The table below shows key findings:

|

Study Focus |

Insights |

Problems |

Growth Ideas |

|---|---|---|---|

|

Medical Robots |

Neural networks for control |

Needs testing in hard cases |

Modular designs help growth |

|

Multi-Robot Systems |

Fast response and teamwork |

Needs growth testing |

Better data and teamwork help |

Microcontrollers with modular designs and enough memory support growth. For example, a simple robot can later add AI or sensors. Picking a microcontroller with extra pins, strong power, and enough memory keeps the robot ready for the future.

Developers should also check if it works with updates and new parts. A scalable microcontroller saves money and makes the robot last longer. It’s a smart choice for humanoid robots.

Popular MCUs Used in Humanoid Robots

Overview of Leading MCU Brands

Humanoid robots need advanced microcontrollers to do hard tasks. These tasks include motor control, using sensors, and making quick decisions. Some top brands make special MCUs for robots. Here are a few examples:

-

Microchip Technologies Inc.: Makes the PIC32CM LS60. It has Arm TrustZone for safety and easy development.

-

Texas Instruments Incorporated: Offers tools for Wi-Fi and thread SimpleLink MCUs, great for IoT and robots.

-

STMicroelectronics: Creates the STM32C0 series, a low-cost 32-bit MCU for home and industrial use.

-

NXP Semiconductors: Provides the MCUXpresso toolset, which helps build scalable robot systems.

-

Renesas Electronics Corporation: Built an MCU with 22-nm tech for better speed and less power use.

These brands lead in MCU innovation, helping both hobbyists and researchers build humanoid robots.

Comparison of Features and Specifications

Picking the right MCU means knowing its specs. Below is a table comparing popular MCUs:

|

Feature |

ESP32-C3 |

SiFive FE310 |

GD32VF103 |

K210 |

|---|---|---|---|---|

|

Processor Type |

RISC-V |

RISC-V |

RISC-V |

RISC-V |

|

Memory Size |

520 KB RAM |

16 KB RAM |

64 KB RAM |

8 MB RAM |

|

Clock Speed |

240 MHz |

1.5 MHz |

108 MHz |

400 MHz |

|

Power Consumption |

Low |

Low |

Medium |

Medium |

|

Communication Protocols |

Wi-Fi, Bluetooth |

SPI, I2C |

SPI, I2C |

SPI, I2C, UART |

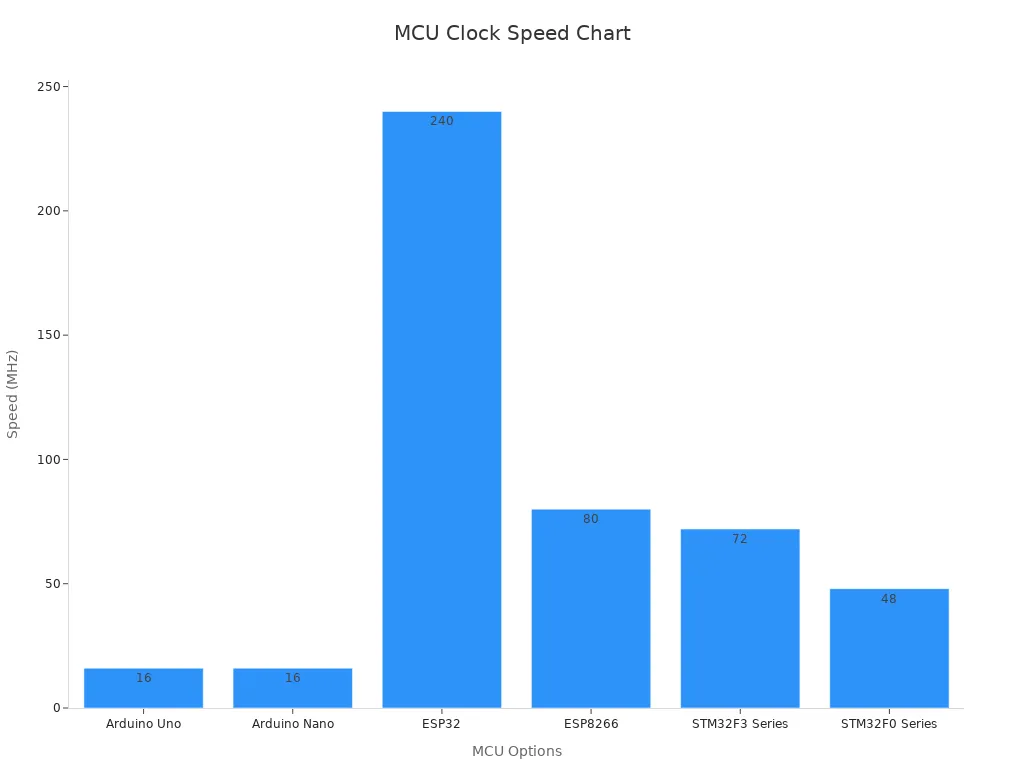

Here’s another table comparing Arduino boards and STM32 MCUs:

|

Feature |

Arduino Uno |

Arduino Nano |

ESP32 |

ESP8266 |

STM32F3 Series |

STM32F0 Series |

|---|---|---|---|---|---|---|

|

Chip used |

ATmega328P |

ATmega328P |

Tensilica LX6 |

Tensilica L106 |

ARM Cortex-M4 |

ARM Cortex-M0 |

|

Memory Size (RAM) |

2 KB |

2 KB |

520 KB |

64 KB |

Up to 80 KB |

4-32 KB |

|

Flash Memory |

32 KB |

32 KB |

4-16 MB |

1 MB |

Up to 256 KB |

16-256 KB |

|

Clock Speed |

16 MHz |

16 MHz |

240 MHz |

80 MHz |

72 MHz |

48 MHz |

|

Power Consumption |

Low |

Low |

Medium |

Low |

Medium |

Low |

This data shows how different MCUs work. It helps developers pick the best one for their robot.

Suitability of Each MCU for Humanoid Robotics Applications

Different MCUs are good for different robot types. Their use depends on the robot’s needs. Here’s a guide:

High-End / Research-Grade Humanoid Robots

These robots need powerful MCUs for fast processing:

-

STM32H7 / STM32F7 (STMicroelectronics): Great for motor control and sensor tasks with 480 MHz speed.

-

TI Sitara AM335x / AM64x: Combines Linux support with real-time control for complex robots.

-

NXP i.MX RT Series: Perfect for vision, motion, and sound tasks.

-

Renesas RA6M4 / RX72M: Good for precise motor control and timing.

Mid-Level Humanoid Robots (Educational / DIY / Hobby)

Simpler robots need cheaper and easy-to-use MCUs:

-

STM32F4 / STM32F1 (STMicroelectronics): Popular for robot arms and supported by open-source tools.

-

ESP32 (Espressif): Dual-core with Wi-Fi and Bluetooth, ideal for sensors and wireless tasks.

-

Arduino Mega / Due: Beginner-friendly boards for basic robots.

Use-Case Specific Recommendations

Some MCUs are best for specific tasks:

-

Motor Control: STM32F3, STM32G4, RX66T, TI C2000 (F28069)

-

Sensor Fusion: STM32H7, i.MX RT1062, Teensy 4.1

-

Wireless Communication: ESP32, NRF52

-

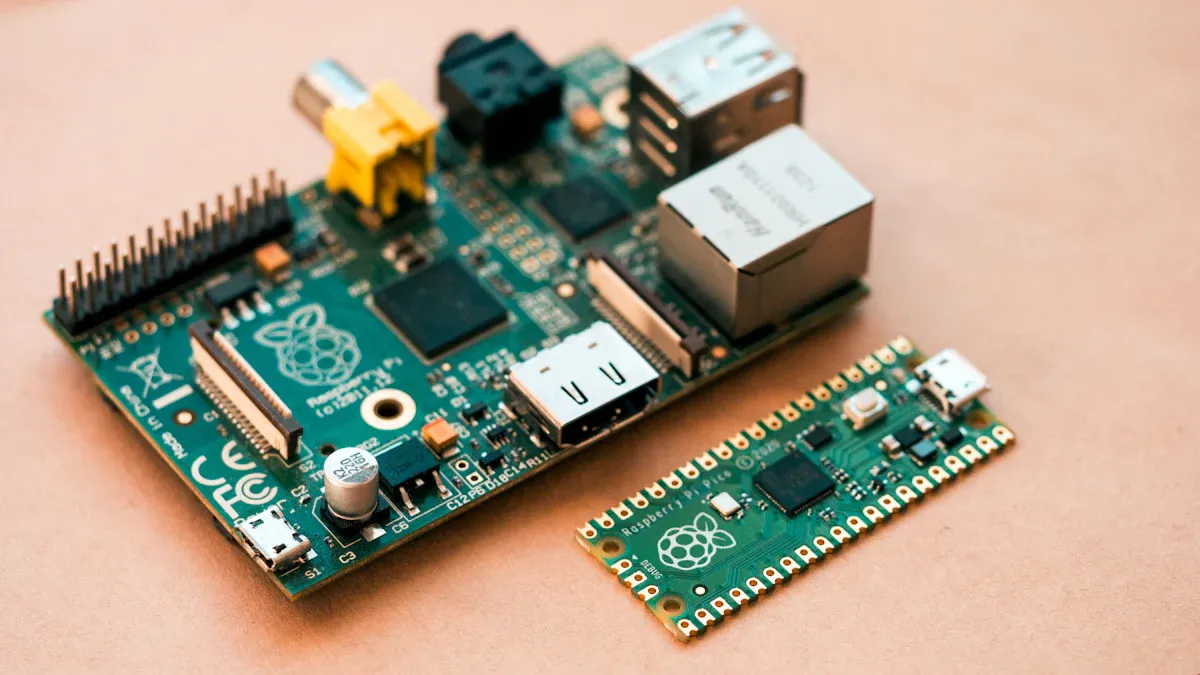

Vision Processing: Raspberry Pi CM4, Jetson Nano (MPU, not MCU)

-

Speech and AI: RP2040 (Pico), ESP32-S3, external AI co-processors

Humanoid robots need MCUs that handle sensors, motors, and communication. Developers can choose from these popular options based on their robot’s complexity.

Applications of Microcontrollers in Humanoid Robots

Motor Control for Joint Movement

Microcontrollers help control motors in humanoid robots. These motors allow robots to move joints like humans. Robots can walk, lift, or grab objects with precise motor control. Microcontrollers read sensor data and send commands to motors. This ensures smooth and accurate movements. For example, a robot arm lifting something adjusts torque and speed in real time.

Microcontrollers use Pulse Width Modulation (PWM) to control motors. PWM changes the signal’s duty cycle to adjust motor speed and direction. This helps robots perform tasks needing precision and skill.

Sensor Integration for Environmental Awareness

Microcontrollers also connect sensors to robots for environmental awareness. Sensors like cameras, LiDAR, and ultrasonic modules collect data about surroundings. Microcontrollers process this data to help robots avoid obstacles and interact with their environment.

Here’s a table showing sensor integration benefits:

|

Performance Metrics/Analyses |

Description |

|---|---|

|

Evaluation of Sensor Technology |

Checking how well sensors measure air pollutants. |

|

Development of Integrated Solutions |

Combining different sensor technologies for better solutions. |

|

Enhancement of Monitoring Activities |

Improving air quality monitoring by communities. |

|

Provision of Local Air Quality Data |

Giving detailed data near pollution sources. |

|

Public Access Improvement |

Making air monitoring easier for personal use. |

|

Characterization of Air Quality |

Learning more about air quality and emissions. |

This helps robots do tasks like monitoring air quality or detecting objects, making them useful in real life.

Human-Machine Interaction (Voice Recognition, Gesture Control)

Microcontrollers make robots understand voice commands and gestures. This makes communication with humans easier. Voice recognition systems use microcontrollers to process sounds and match them to commands. Gesture control uses image processing to detect hand movements.

The table below compares voice and gesture recognition performance:

|

Model Type |

Accuracy (Unsegmented) |

Accuracy (Segmented) |

Notes |

|---|---|---|---|

|

Hand Gesture Recognition |

45% |

58% |

Better results with image segmentation; image quality matters. |

|

Image Processing Techniques |

N/A |

N/A |

Lighting and camera type affect gesture recognition. |

|

Demographic Representation |

N/A |

N/A |

Lack of diverse training data can cause biased results. |

These features help robots understand and respond to humans better. Advanced microcontrollers improve the accuracy and reliability of these systems.

Real-Time Decisions and AI in Robots

Making quick decisions is very important for humanoid robots. Microcontrollers help robots process data fast and react right away. This is needed for tasks like avoiding obstacles, moving on their own, or talking to people. Low-power microcontrollers work locally, cutting delays and speeding up responses. This is crucial in situations where slow reactions could cause mistakes or danger.

Adding artificial intelligence (AI) to microcontrollers makes them smarter. AI helps robots find patterns, guess results, and decide on their own. For example, health devices use microcontrollers to check body data instantly. They can spot problems and send alerts quickly, showing how useful AI and microcontrollers are together.

Some advanced microcontrollers, like Texas Instruments’ TMS320F28P55x series, have special AI hardware. These chips include an AI accelerator that boosts control and finds errors with 99% accuracy. Their neural processing unit (NPU) makes them 5-10 times faster than older software methods. This makes them perfect for jobs needing quick data handling and decisions.

AI and microcontrollers together bring more than speed. They also save energy and keep data private. By working locally, robots use less power and avoid sending data to the cloud. This protects sensitive information. These features make AI-powered microcontrollers a key part of today’s humanoid robots.

Picking the right microcontroller (MCU) is very important for making humanoid robots work well. The MCU is like the robot’s brain. It helps control motors, connect sensors, and make quick decisions. Builders should focus on three main things: how well it works, how it fits with other parts, and how much it costs.

Tip: First, think about what the robot needs. Check its processing power, memory size, and ways to connect.

Look at different MCU choices by their features and ability to grow. Choose one that can be upgraded later and saves energy. A good MCU makes the robot better and helps the project succeed for a long time.

What makes an MCU different from an MPU?

An MCU (Microcontroller Unit) has a processor, memory, and peripherals in one chip. An MPU (Microprocessor Unit) focuses only on processing and needs extra parts for memory and peripherals. MCUs are better for robots because they are small and complete.

How much memory does a robot’s MCU need?

Memory size depends on the robot’s tasks. Simple robots need 32 KB to 256 KB of flash storage and 2 KB to 32 KB of RAM. Robots with AI or vision need more, like several megabytes of RAM and flash storage.

Can Arduino boards be used for humanoid robots?

Arduino boards are good for basic robots or learning projects. For advanced robots, use MCUs like STM32 or ESP32. These have more power, memory, and better connection options.

How can I make my MCU ready for upgrades?

Pick an MCU with extra pins, enough memory, and modular design support. This helps add new features like AI, sensors, or better connections without replacing the MCU.

What MCU is best for wireless robot communication?

For wireless tasks, ESP32 and NRF52 are great options. ESP32 works with Wi-Fi and Bluetooth, while NRF52 is best for Bluetooth Low Energy (BLE). Both save power and connect well over long distances.

See Also

Harnessing RV1126 for AI-Driven Robotics Edge Computing

Integrating AEAT-8800-Q24 to Improve Robotics Efficiency

Using STM32F103C8T6 for Bluetooth Control in Robotics

Enhancing Automotive Performance with NXP MC9S12 Microcontrollers

SPC56 Microcontrollers Provide Simple Solutions for Engine Control