Introduction: The Cornerstone of Power Integrity Design

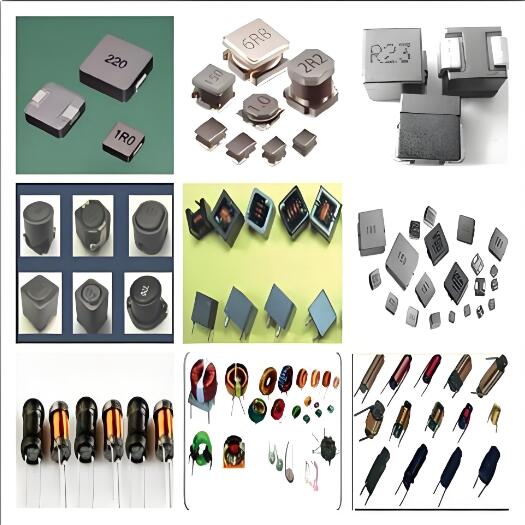

In modern electronic systems, the Voltage Regulator Module (VRM) and Voltage Regulator Down (VRD) play pivotal roles, directly impacting system stability, efficiency, and overall performance. Within these systems, the inductor, as a critical component for energy storage and filtering, has a decisive influence on the quality of the VRM/VRD. As an engineer with years of experience in power design, I deeply understand the significant advantages a high-quality inductor can bring to a design. Today, we will delve into the Coilcraft XPL2010 series of shielded power inductors and explore why they stand out in numerous VRM/VRD applications, becoming the preferred choice for engineers.

Core Technical Advantages of Coilcraft XPL2010

The Coilcraft XPL2010 series is no ordinary component; its exceptional performance stems from unique design concepts and advanced manufacturing processes. Here are several key technical highlights, representing advantages I have repeatedly verified in practical projects:

1. Exceptional Soft Saturation Characteristics: The Guardian of Stability

Soft saturation is a key metric measuring how smoothly an inductor’s value decreases as current increases. Traditional inductors experience a sharp drop in inductance at the saturation point, leading to current spikes, increased ripple, and potential system instability. The soft saturation characteristic of the XPL2010 means that even under heavy loads or transient current surges, its inductance value decreases gradually rather than precipitously. This is profoundly significant for VRM/VRD systems:

-

Smoother Current Response: Prevents current runaway caused by sudden inductance drops, effectively suppressing output voltage ripple and noise.

-

Enhanced System Stability: Allows the system to handle drastic load changes more gracefully, reducing overshoot and undershoot, thus ensuring stable power output.

-

Optimized Transient Response: The soft saturation enables VRM/VRDs to provide faster transient responses under rapidly changing loads, which is crucial for components like CPUs and GPUs that demand high power quality.

In my practical experience, particularly when designing high-performance server or data center power supplies, the XPL2010’s soft saturation characteristic greatly simplified loop compensation challenges and enhanced system reliability under extreme operating conditions. We encountered a case where a specific processor generated immense inrush current during startup, causing frequent system reboots with a standard inductor. After switching to the XPL2010, the problem was resolved, fully demonstrating its robust capability in handling transient loads.

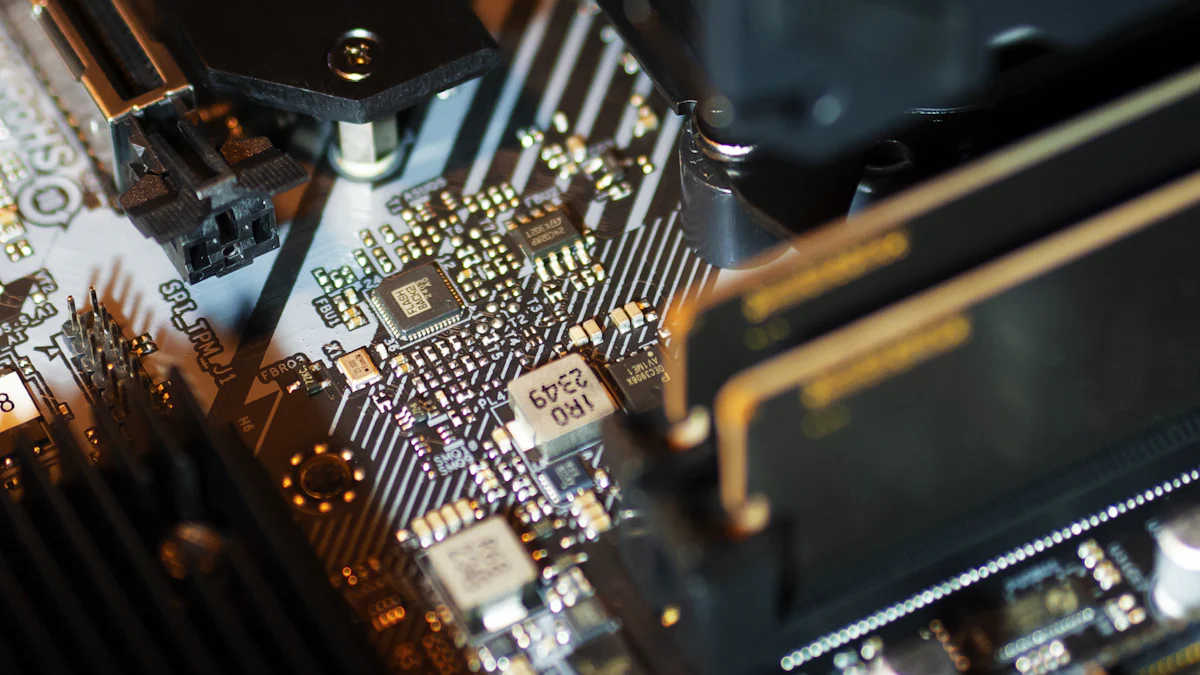

2. Ingenious Low-Profile Design: A Paradigm of Space Efficiency

As electronic products trend towards miniaturization and integration, PCB space is at a premium. The XPL2010 series inductors employ a low-profile design, allowing them to deliver high performance while fitting perfectly into compact devices.

-

Optimal Space Utilization: For instance, the XPL2010-222ML model, with its 2.2µH inductance and wide operating temperature range of -40°C to +125°C, packs powerful functionality into a minimal footprint. This is a significant boon for laptops, smartphones, wearable devices, and various embedded systems.

-

High Power Density: The low-profile design does not compromise performance. Through optimized core material and winding technology, Coilcraft ensures the XPL2010 can handle high currents even within its small size, achieving high power density.

I participated in the power module design for a high-end consumer drone where internal space was extremely limited, with strict height restrictions for components. The XPL2010’s low-profile design allowed us to successfully integrate the power module into the narrow fuselage without sacrificing performance, a feat difficult to achieve with other inductor alternatives at the time.

Tangible Benefits Offered by XPL2010: Beyond the Datasheet

Selecting an inductor isn’t just about reviewing its electrical parameters; it’s crucial to understand the practical, perceptible benefits it brings to the entire system. The XPL2010 excels notably in this regard:

1. Significantly Improved Power Conversion Efficiency: A Win-Win for Energy Saving and Thermal Management

Efficiency is the eternal pursuit of power design. The XPL2010 effectively enhances VRM/VRD conversion efficiency through the following:

-

Low DC Resistance (DCR): DCR is the internal resistance of the inductor winding. Lower DCR results in reduced copper losses (I²R losses) when current passes through. The XPL2010’s low DCR design significantly cuts energy loss and minimizes heat generation.

-

Optimized Core Losses: The choice of core material and structural design directly affect core losses (including eddy current and hysteresis losses). The XPL2010 utilizes a high-performance core, maintaining very low core losses even at switching frequencies, further boosting efficiency.

In my testing, VRM/VRD modules using the XPL2010 exhibited noticeably lower temperature rises under equivalent output power compared to modules using standard inductors. This translates not only to energy savings but also reduced pressure on thermal design and extended system lifespan. In demanding scenarios like data centers, the XPL2010 can contribute significantly to operational cost savings.

2. Exceptional Reliability in Harsh Environments: The Ideal Choice for Industrial and Automotive Applications

Many electronic devices must operate reliably in extreme environments, such as automotive electronics, industrial control systems, and outdoor communication equipment. The XPL2010 series inductors demonstrate outstanding reliability and durability thanks to their robust construction and high-quality materials:

-

Wide Operating Temperature Range: The -40°C to +125°C range ensures stable inductor performance without drift or failure in bitterly cold or scorching hot conditions.

-

Resistance to Vibration and Shock: The shielded structure not only helps reduce EMI but also provides excellent mechanical protection for the internal windings, enabling it to withstand severe vibration and shock—critical for automotive and industrial automation applications.

-

Long-Life Design: High-quality materials and precision manufacturing guarantee a longer service life for the XPL2010, reducing equipment maintenance costs and failure rates.

In an industrial robotics project I worked on, inductors were failing frequently in the harsh environment of high temperature and intense vibration, causing production line interruptions. After switching to the XPL2010, long-term operation verified its stable and reliable performance, completely resolving this pain point. This experience shows that the initial investment cost is fully justified when considering reliability.

Practical Application Cases and Engineer Insights

The XPL2010 series inductors have been widely adopted in several critical fields and have earned high praise from engineers. Below are some specific application scenarios and my personal experience sharing:

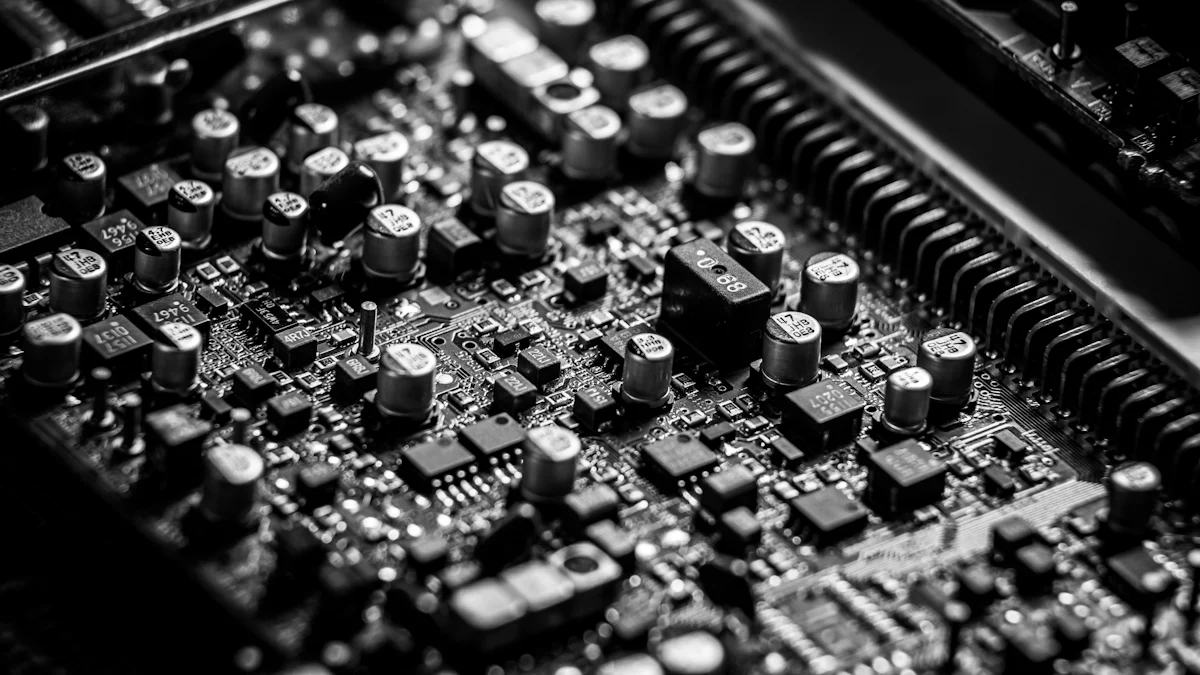

1. High-Performance Computing (HPC) & Data Centers

In servers, supercomputers, and data centers, CPUs/GPUs demand extremely high power supply transient response and ripple rejection. The XPL2010’s soft saturation and high efficiency make it an ideal choice for HPC VRMs. It ensures processors receive clean, stable power during rapid load switching, preventing performance degradation or crashes.

Engineer Insight: When designing multi-phase VRMs, the XPL2010’s low DCR and excellent thermal performance allowed us to achieve higher current density without increasing heatsink size. This is an invaluable advantage for server board designs in data centers pursuing extreme computational density.

2. Automotive Electronics

Automotive electronic systems face challenges of wide temperature ranges, high vibration, and high reliability. The XPL2010’s rugged construction and wide temperature characteristics make it highly suitable for DC-DC converters within automotive infotainment systems, ADAS modules, and powertrain control units.

Engineer Insight: In automotive power design, EMI is a major concern. The XPL2010’s shielded design effectively suppresses electromagnetic radiation, helping us pass stringent automotive EMC tests smoothly and reducing post-design debugging hassles.

3. Portable & Wearable Devices

For space-constrained portable devices (e.g., laptops, tablets, smartwatches), the XPL2010’s low-profile design and high efficiency are its core competitive advantages. It helps extend battery life and enables slimmer product form factors.

Engineer Insight: When designing the circuitry around Power Management ICs for wearable devices, the XPL2010’s small size allowed us to complete the power design within an extremely limited PCB area. Simultaneously, its high efficiency provided a solid foundation for battery life, enhancing the user experience.

4. Industrial Automation & Communication Equipment

Industrial equipment demands high reliability and stability, while communication base stations require long-term stable operation. In these scenarios, the XPL2010 provides stable power output and withstands the challenge of harsh industrial environments.

Engineer Insight: While designing the power section for an industrial Ethernet switch, we observed that the XPL2010 maintained excellent temperature control even under prolonged, high-load operation. This is key to ensuring long-term, stable operation for industrial equipment requiring 24/7 uptime.

Conclusion: A Prudent Choice for Excellent Design

The Coilcraft XPL2010 series shielded power inductors, with their unique soft saturation characteristics, ingenious low-profile design, outstanding power conversion efficiency, and exceptional reliability in harsh environments, undoubtedly stand out as a top performer in the VRM/VRD application field. As an engineer, I firmly believe that selecting the right components is a crucial step towards project success. The XPL2010 not only delivers superior electrical performance but also demonstrates strong adaptability and stability in practical applications, helping us solve numerous design challenges and enhancing the overall competitiveness of our products. For power designs pursuing high performance, high reliability, and high efficiency, the Coilcraft XPL2010 is undoubtedly a trustworthy and wise choice.

See Also

Revolutionizing Industrial Automation with XCF01SVOG20C Top 3 Methods

Key Features of SPC5605BMLL6 and SPC5607BMLL6 ECU Revealed

Effortless Engine Control Solutions with SPC56 Microcontrollers

Sustaining Electronics Excellence through Booming Technology

Diving into Automotive Applications with MC9S12DJ256MFUE Specs