The DRV8701ERGER, along with the DRV8701PRGER and DRV8701, is a versatile gate driver designed to optimize the performance of brushed DC motors across automotive, industrial, and smart home applications. Supporting H-bridge configurations, it enables precise motor control and provides robust protection for external MOSFETs. Brushed DC motors continue to be a popular choice due to their cost-effectiveness and adaptability in systems such as conveyor belts, power seats, and motorized blinds. The DRV8701ERGER delivers advanced features like high-side switching, low Rds(on), and reliable diagnostic outputs, making it an excellent solution for developers focused on efficiency and durability in motor control systems.

Key Takeaways

-

The DRV8701ERGER motor driver helps control brushed DC motors better. It works well for things like car seats and conveyor belts.

-

It has safety features like overcurrent and thermal shutdown. These protect the motor and driver from getting damaged.

-

Its wide voltage range (5.9V to 45V) lets it work in many devices, like cars and smart home gadgets.

-

The small size (4×4 mm) of the DRV8701ERGER fits in tight spaces. This makes it easy to use in small designs.

-

Developers can use the DRV8701EVM module to test motor systems. This helps them build projects faster.

What is the DRV8701ERGER Motor Driver?

Overview of the DRV8701ERGER

Purpose and role in motor control

The DRV8701ERGER serves as a brushed DC gate driver, designed to enhance motor control systems by managing external FETs in H-bridge or half-bridge configurations. It acts as a gate driver, enabling precise control over motor speed, direction, and torque. This driver also ensures system reliability through built-in protection features like overcurrent and thermal shutdown. By supporting high-side switching, it efficiently controls the positive side of the load, reducing power loss and heat generation. Its diagnostic outputs further assist in monitoring system status and detecting faults, making it a dependable choice for motorized applications.

Compatibility with brushed DC motors

The DRV8701ERGER is specifically tailored for brushed DC motors, which are widely used in automotive, industrial, and smart home systems. Its compatibility with these motors allows it to support applications such as power seats, conveyor belts, and motorized blinds. The driver’s ability to regulate current and provide bidirectional control ensures smooth operation and precise performance. Its low standby power mode also makes it suitable for energy-efficient designs.

Key Specifications

Voltage and current handling capabilities

The DRV8701ERGER offers robust voltage and current handling capabilities, making it suitable for a wide range of motor control applications. The table below highlights its key parameters:

|

Parameter |

Value |

|---|---|

|

Maximum Voltage (Vs ABS max) |

47 V |

|

Minimum Voltage (Vs min) |

5.9 V |

|

Sleep Current |

9 µA |

|

Operating Temperature Range |

-40 to 125 °C |

These specifications ensure the driver can operate reliably under varying conditions, from low-power smart home devices to high-power industrial systems.

Integration with external MOSFETs

The DRV8701ERGER integrates seamlessly with external FETs, enabling flexible motor control configurations. It supports both H-bridge and half-bridge setups, allowing developers to adapt the system to different motor sizes and power levels. The driver’s low Rds(on) minimizes power loss, while its adjustable current regulation ensures precise motor operation. These features make it an ideal choice for applications requiring efficient and scalable motor control solutions.

Key Features of the DRV8701ERGER

Wide Operating Voltage Range

Voltage flexibility from 5.9V to 45V

The DRV8701ERGER offers a wide operating voltage range, making it suitable for diverse applications. This flexibility allows the driver to accommodate varying voltage requirements in industrial systems, automotive solutions, and consumer devices. For example:

-

Industrial applications benefit from its ability to handle different voltage levels, ensuring compatibility with factory automation systems.

-

Automotive systems, such as electric power steering, rely on this range for stable operation.

-

Consumer devices, including motorized blinds, take advantage of its adaptability to function in different environments.

Support for 12V and 24V industry standards

The DRV8701ERGER supports standard voltages like 12V and 24V, which are common in automotive and industrial applications. Its high-side switching capability enables precise control of the positive side of the load, ensuring efficient operation. The driver also includes adjustable current limiting and a PWM input interface, enhancing its versatility. Additionally, built-in protection features, such as overcurrent and thermal shutdown, ensure reliable performance at these voltages.

System Flexibility and Scalability

PH/EN and PWM interface options

The DRV8701ERGER provides both PH/EN and PWM interface options, offering developers flexibility in motor control. These interfaces simplify integration into various systems, enabling precise speed and direction control. The PWM interface, in particular, allows for efficient modulation of motor speed, making it ideal for applications requiring fine-tuned performance.

Adaptability to various motor sizes and power levels

This driver adapts to different motor sizes and power levels, enhancing its usability across a wide range of applications. It supports various motor types, including DC motors and brushless motors, making it suitable for robotics, industrial automation, and consumer electronics. Its adjustable gate drive settings allow developers to select external FETs and scale gate-drive current as needed. This adaptability ensures precise speed and position control, even for motors with varying power requirements.

Built-in Protection Features

Overcurrent and thermal shutdown protection

The DRV8701ERGER includes robust protection features to enhance system reliability. Overcurrent protection prevents excessive current from damaging the driver or motor. Thermal shutdown protection automatically disables the driver when it overheats, safeguarding the system from potential harm. These features ensure the driver operates safely under demanding conditions.

Fault diagnostics for enhanced reliability

Fault diagnostics provide valuable feedback on system performance. The driver’s fault flag indication alerts users to issues such as overcurrent or undervoltage conditions. This feature simplifies troubleshooting and ensures the system remains reliable over time. By integrating on-chip protection mechanisms, the DRV8701ERGER minimizes the risk of system failure, making it a dependable choice for motor control applications.

Compact Design

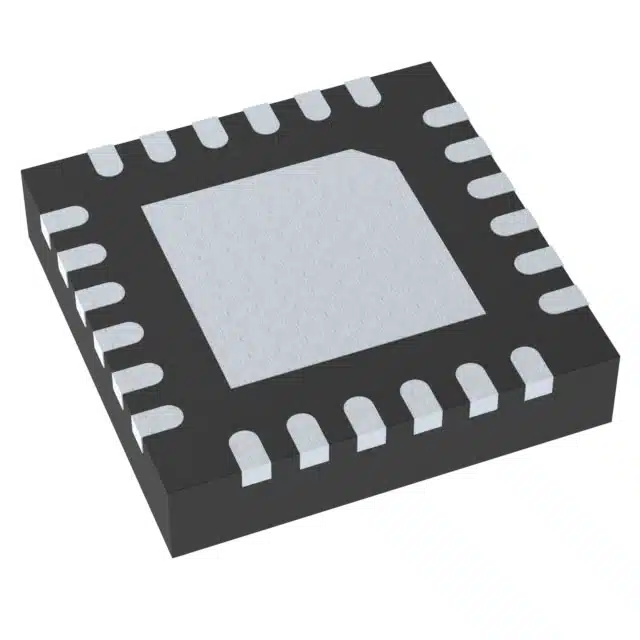

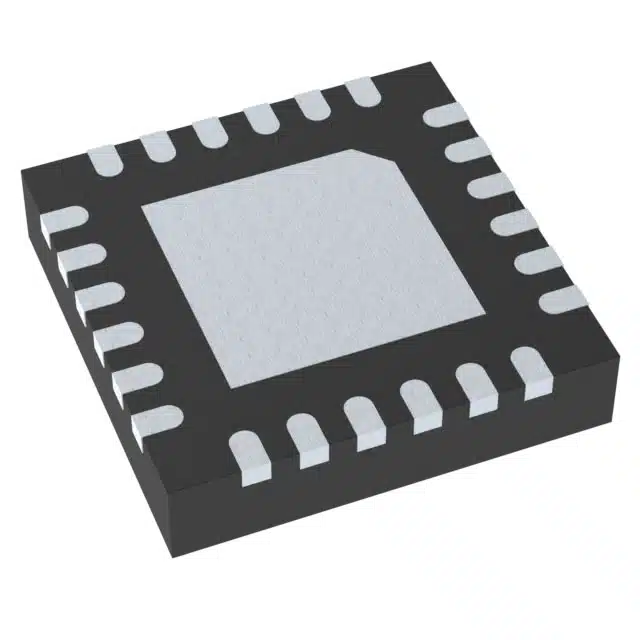

24-VQFN (4×4) package for space-constrained applications

The DRV8701ERGER motor driver incorporates a compact 24-pin QFN (Quad Flat No-lead) package, measuring just 4×4 mm. This small footprint minimizes the space required for integration into motor control systems. Developers can implement advanced motor control features in applications where space is limited. This design proves especially beneficial for automotive and industrial systems, where compactness is critical. For example, motorized systems in vehicles, such as power seats or sunroofs, often have restricted space for electronic components. The compact package ensures that robust motor control and protection capabilities fit seamlessly into these environments without compromising performance.

The QFN package also enhances thermal performance by providing efficient heat dissipation. This ensures the driver operates reliably, even in high-power applications. Its compact design allows engineers to optimize PCB layouts, reducing overall system size while maintaining functionality. This makes the DRV8701ERGER an excellent choice for space-constrained applications like smart home devices and robotic actuators.

Low standby power for energy efficiency

The DRV8701ERGER offers low standby power consumption, with a sleep current of just 9 µA. This feature makes it ideal for energy-efficient applications. Systems that operate intermittently, such as motorized blinds or locks, benefit significantly from this low-power mode. By reducing power consumption during idle periods, the driver helps extend battery life in portable or battery-powered devices.

In automotive applications, low standby power contributes to overall vehicle energy efficiency. For instance, electronic parking brakes and window lift motors can remain in standby mode without draining the vehicle’s battery. This ensures reliable operation while conserving energy. The combination of low standby power and a compact design makes the DRV8701ERGER a versatile solution for modern motor control systems.

Benefits for Brushed DC Motor Applications

Simplified Design and Reduced Complexity

Streamlined motor control with fewer external components

The DRV8701ERGER simplifies motor control design by reducing the need for additional components. Its built-in protection mechanisms, including overcurrent protection, under-voltage lockout, and thermal shutdown, eliminate the need for external circuitry. This integration streamlines the design process and minimizes the overall system footprint. Additionally, the driver supports various motor types, such as DC motors and brushless motors, making it a versatile solution for developers. Its precise speed and position control capabilities further enhance its usability in diverse applications.

Adjustable current regulation for precise control

The adjustable current regulation feature of the DRV8701ERGER allows developers to fine-tune motor performance. By setting the current limit appropriately, the driver ensures the motor operates within its optimal range. This prevents issues like underpowering or overheating, which could compromise system reliability. The ability to regulate current also enables precise control over motor speed and torque, making the driver suitable for applications requiring high accuracy.

Improved Motor Performance

Enhanced speed and torque control

The DRV8701ERGER enhances motor performance by enabling precise speed and torque control. Proper calibration of the driver, including current limit adjustments, ensures the motor operates efficiently without excessive heating. This calibration also optimizes the motor’s power output, resulting in improved performance. Additionally, the driver supports microstepping settings, which reduce noise and vibration while ensuring smooth movement. These features make it an excellent choice for applications demanding high-performance motor control.

Reduced noise and vibration for smoother operation

The DRV8701ERGER minimizes noise and vibration during motor operation. Its advanced control features, such as PWM modulation and current regulation, contribute to smoother motor movement. This reduction in noise and vibration enhances the user experience, particularly in applications like motorized blinds or power seats, where quiet operation is essential.

Versatility Across Applications

Automotive uses like EPB and power seats

The DRV8701ERGER is widely used in automotive applications due to its robust features and reliability. For example, it controls motors in electronic parking brakes (EPB) and power seat adjustment systems. The driver’s ability to handle bidirectional motor control and provide built-in protection ensures safe and efficient operation.

|

Application Type |

Description |

|---|---|

|

Electric Vehicles |

Designed for electric vehicle motor control applications, including traction motor drives and accessory motor controls. |

|

Automotive Body Control Modules |

BCMs control various electrical components in a vehicle, such as lights, wipers, and window motors. The DRV8701ERGER can be used to switch power to these loads. |

|

In circuits controlling small motors, the DRV8701ERGER can be used to turn the motor on and off or to control its speed by modulating the power supply. |

Industrial and smart home motorized systems

The DRV8701ERGER also excels in industrial and smart home applications. It supports a wide operating voltage range and provides robust protection features, making it suitable for controlling motors in conveyor belts, robotic actuators, and motorized blinds. Its adaptability to different motor sizes and power levels ensures reliable performance across various use cases. For instance, in smart home systems, the driver enables precise control of motorized locks and appliances, enhancing convenience and efficiency.

Tools and Support for the DRV8701ERGER

Evaluation Modules

Available kits for testing and prototyping

The DRV8701EVM serves as the primary evaluation module for the DRV8701ERGER motor driver. This kit demonstrates the capabilities of the H-bridge gate driver and simplifies testing and prototyping. It includes an MSP430G2553 microcontroller for motor speed and direction control. The module also monitors motor current and integrates the DRV8701 with CSD18532Q5B N-channel NexFET power MOSFETs.

|

Feature |

Description |

|---|---|

|

Evaluation Module |

DRV8701EVM demonstrates the DRV8701 H-bridge gate driver. |

|

Control |

MSP430G2553 manages motor speed and direction. |

|

Monitoring |

Tracks motor current from the DRV8701. |

|

Power Stage |

Utilizes DRV8701 and CSD18532Q5B MOSFETs for efficient operation. |

|

Performance |

Provides a high-performance, cost-effective platform for faster development. |

|

User Interface |

Features a user-friendly application for easy operation with minimal external equipment. |

This evaluation module offers a reliable platform for developers to test motor control systems efficiently. Its design ensures compatibility with various applications, from automotive to industrial systems.

How to use evaluation modules effectively

To maximize the benefits of the DRV8701EVM, developers should follow a structured approach. Begin by connecting the module to the motor and power supply. Use the MSP430G2553 microcontroller to adjust motor speed and direction. Monitor motor current to evaluate performance and ensure proper operation. The user-friendly interface simplifies setup and operation, allowing developers to focus on optimizing motor control parameters. This process accelerates prototyping and reduces development time.

Documentation and Resources

Datasheets, application notes, and design guides

Comprehensive documentation supports the DRV8701ERGER motor driver. The datasheet provides detailed specifications, including voltage ranges, current limits, and protection features. Application notes and design guides offer practical insights into integrating the driver into motor control systems. These resources help developers address common challenges and ensure smooth operation.

The DRV8701ERGER datasheet explains its wide operating voltage range, adjustable current limiting, and built-in protection features. These documents guide developers in creating reliable and efficient motor control solutions.

Online forums and community support

Online forums and communities provide valuable support for DRV8701ERGER users. Developers can share insights, troubleshoot issues, and stay updated on best practices. Active participation in these communities fosters collaboration and enhances understanding of the driver’s capabilities.

-

Users exchange tips and solutions for optimizing motor control systems.

-

Communities keep developers informed about the latest updates and techniques.

These resources empower developers to leverage the full potential of the DRV8701ERGER in their applications.

The DRV8701ERGER motor driver stands out as a reliable and versatile solution for brushed DC motor control. Its advanced features, such as high-side switching and diagnostic outputs, simplify integration and enhance system performance. Engineers and hobbyists value this driver for its robust protection mechanisms, including overcurrent protection and thermal shutdown, which ensure safe operation in demanding environments.

This driver supports precise speed and position control, making it suitable for high-performance applications. Developers can leverage its compact design and low Rds(on) to create efficient motor control systems that minimize power loss and heat generation. These attributes make the DRV8701ERGER an ideal choice for automotive, industrial, and smart home applications.

|

Feature |

Description |

|---|---|

|

High-Side Switching |

Operates as a high-side switch, allowing control of the positive side of the load. |

|

Protection Features |

Includes overcurrent protection, thermal shutdown, and undervoltage lockout. |

|

Low Rds(on) |

Reduces power loss and heat generation due to low on-state resistance. |

|

Diagnostic Outputs |

Provides outputs to monitor switch status and detect faults. |

The DRV8701ERGER empowers developers to design compact, efficient systems while ensuring reliable motor performance across diverse applications.

What types of motors are compatible with the DRV8701ERGER?

The DRV8701ERGER works with brushed DC motors. These motors are commonly used in automotive, industrial, and smart home applications. Its compatibility ensures smooth operation and precise control in systems like power seats, conveyor belts, and motorized blinds.

How does the DRV8701ERGER protect motor control systems?

The DRV8701ERGER includes overcurrent protection, thermal shutdown, and undervoltage lockout. These features safeguard the motor and driver from damage caused by excessive current, overheating, or low voltage conditions. Fault diagnostics also help identify and resolve issues quickly.

Can the DRV8701ERGER handle high-power applications?

Yes, the DRV8701ERGER supports high-power applications by integrating with external MOSFETs. Its adjustable gate drive settings allow developers to scale power levels for larger motors. This makes it suitable for industrial automation and automotive systems requiring high current.

What is the purpose of the evaluation module for the DRV8701ERGER?

The DRV8701EVM helps developers test and prototype motor control systems. It demonstrates the driver’s capabilities, such as speed and direction control. The module simplifies development by providing a ready-to-use platform for evaluating performance and optimizing designs.

Why is the DRV8701ERGER ideal for space-constrained applications?

The DRV8701ERGER features a compact 24-VQFN (4×4 mm) package. This small size allows it to fit into tight spaces, such as automotive interiors or smart home devices. Its efficient heat dissipation and low standby power further enhance its suitability for compact designs.

See Also

Understanding The IRF820 MOSFET For Power And Control

Delving Into MC9S12DJ256MFUE Specs For Automotive Use

Integrating AEAT-8800-Q24 To Boost Robotics Efficiency

Reasons To Select Coilcraft XPL2010 For VRM Applications

Leveraging AD74413RBCPZ For Improved Process Management