Precision, efficiency, and adaptability are essential for advancing 3D printing and robotics. However, these fields face significant challenges.

|

Challenge |

Description |

|---|---|

|

Spatial Constraints |

The size limitation of printing devices restricts the maximum size of producible objects. |

|

Limitations of Control Systems |

Typical feed-forward control systems do not monitor ongoing processes, leading to potential failures in printing tasks. |

|

Feature Detection Issues |

Problems related to detecting features can hinder the adaptability of 3D printing processes. |

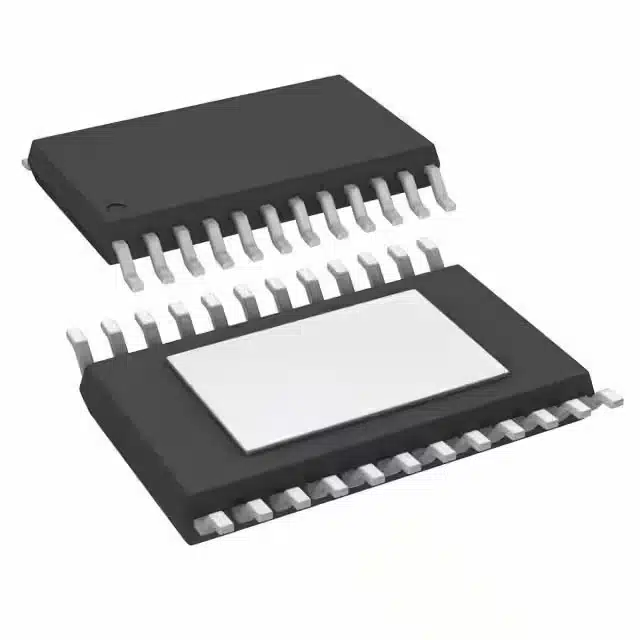

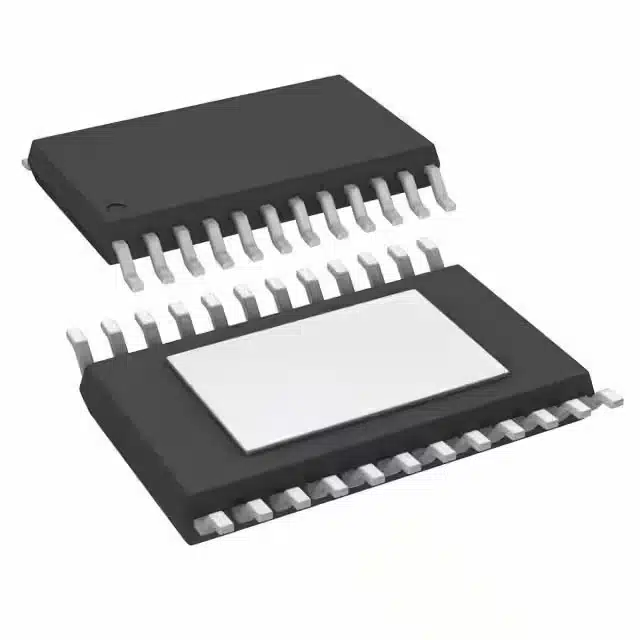

The DRV8885PWPR offers a transformative solution to these challenges. Its microstepping capability ensures smooth motor control, while robust current regulation enhances stability. Integrated protection features, such as thermal shutdown and overcurrent safeguards, improve reliability. Additionally, the nFAULT pin enables quick fault detection, making it ideal for demanding applications. By addressing these issues, the DRV8885PWPR enhances performance, reduces costs, and fosters innovation in motor control systems.

Key Takeaways

-

The DRV8885PWPR improves motor control for better 3D printing and robots.

-

It uses less power and has current sensing to save money.

-

Built-in safety features, like overheating and overcurrent protection, keep it working well.

-

Microstepping helps motors move smoothly, making prints better and designs cooler.

-

The DRV8885PWPR works in many fields, like robots and electric cars.

Key Features of the DRV8885PWPR

Precision Motor Control

The DRV8885PWPR excels in delivering precise motor control, a critical requirement for applications like 3D printing and robotics. Its microstepping capability ensures smooth and accurate motor movements, which is essential for achieving high-quality results. The device supports up to 16 microstepping levels, allowing for fine-tuned control over motor positioning. Additionally, robust current regulation mechanisms maintain stable motor operation, even under varying load conditions.

|

Feature |

Description |

|---|---|

|

Microstepping Capability |

Supports microstepping modes for smooth and precise control. |

|

Current Regulation |

Ensures stable motor operation under dynamic conditions. |

|

Full-scale Current |

1.5 A for effective motor control. |

|

Peak Output Current |

2.3 A to handle dynamic loads. |

This precision enhances accuracy, reduces errors, and improves speed in 3D printing and robotics. It also minimizes maintenance needs by preventing overheating and wear, making it a reliable choice for demanding applications.

Energy Efficiency and Cost Savings

The DRV8885PWPR offers significant energy efficiency, which translates to cost savings for users. Its low RDS(on) output stage minimizes power loss, improving overall system efficiency. The device also features a low-power sleep mode, which conserves energy during standby periods.

-

Key Energy-Saving Features:

-

Low RDS(on) output stage for enhanced efficiency.

-

Low-power sleep mode for minimal energy consumption.

-

Integrated current sensing eliminates the need for external resistors, reducing component count and power loss.

-

These features make the DRV8885PWPR an environmentally friendly solution, as it reduces energy consumption and operational costs in industrial and consumer applications.

Reliability and Safety Features

Reliability and safety are paramount in motor control systems, and the DRV8885PWPR addresses these needs with integrated protection features. The device safeguards against undervoltage, overcurrent, short circuits, and overtemperature conditions. The nFAULT pin provides immediate feedback on fault conditions, enabling quick diagnostics and resolution.

-

Integrated Protection Features:

-

Thermal shutdown to prevent overheating.

-

Overcurrent protection for system stability.

-

Short-circuit protection to avoid damage.

-

These safety mechanisms ensure the DRV8885PWPR operates reliably in critical applications, such as robotics and medical devices, where system failures are not an option.

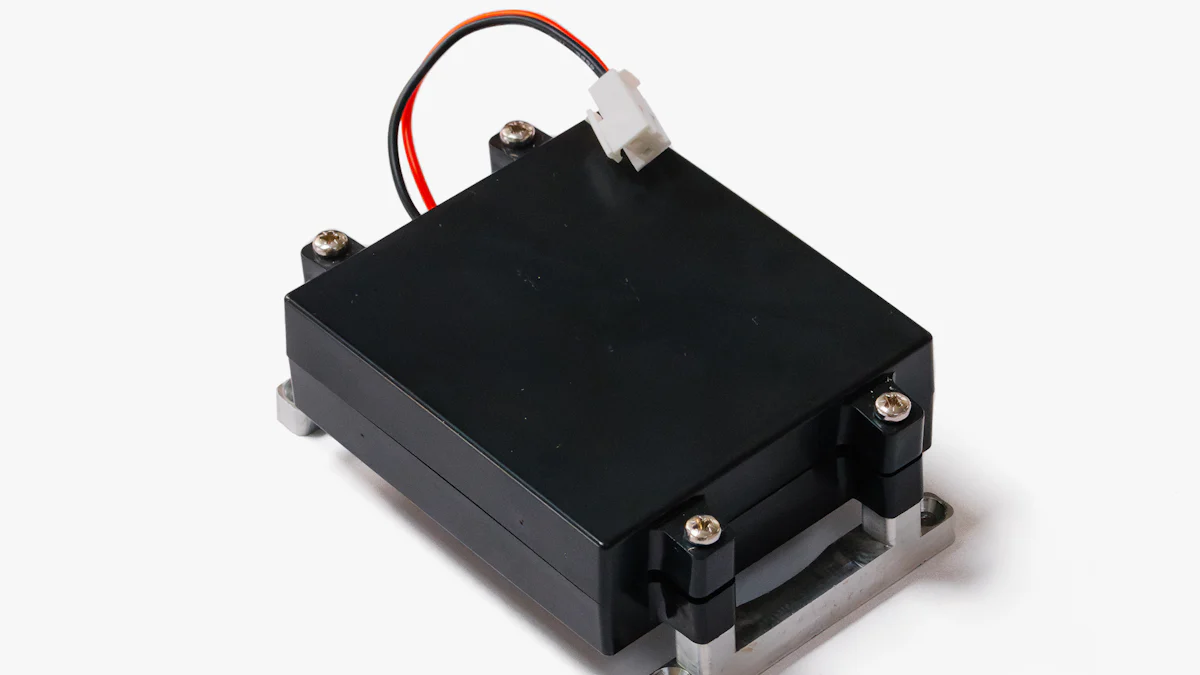

DRV8885PWPR in 3D Printing

Improving Print Quality

The DRV8885PWPR significantly enhances print quality in 3D printing applications. Its microstepping capability ensures smooth and precise motor control, which is essential for achieving detailed and accurate prints. By supporting up to 16 microstepping levels, the device allows for fine adjustments in motor movement. This precision minimizes layer shifting and other common printing errors, resulting in cleaner and more professional outputs.

Additionally, robust current regulation mechanisms maintain stable motor operation under varying load conditions. This stability ensures consistent performance, even during complex printing tasks. The integrated protection features, such as thermal shutdown and overcurrent safeguards, further enhance reliability by preventing motor damage. These attributes make the DRV8885PWPR an ideal choice for improving the overall quality of 3D-printed products.

Reducing Operational Costs

The DRV8885PWPR offers several features that help reduce operational costs in 3D printing. Its low RDS(on) output stage minimizes power loss, improving energy efficiency. The low-power sleep mode conserves energy during idle periods, further reducing electricity consumption. Integrated current sensing eliminates the need for external resistors, lowering component costs and simplifying the design process.

|

Feature |

Description |

|---|---|

|

Microstepping Capability |

Enables smooth and precise motor control, improving print quality and reducing waste. |

|

Current Regulation |

Ensures stable motor operation, minimizing energy consumption and operational costs. |

|

Integrated Protection |

Built-in features like thermal shutdown reduce the risk of damage and maintenance costs. |

These features not only lower energy bills but also reduce maintenance expenses by preventing motor wear and tear. The DRV8885PWPR thus provides a cost-effective solution for 3D printing systems.

Supporting Advanced Customization

The DRV8885PWPR supports advanced customization in 3D printing by enabling precise motor control and consistent performance. Its microstepping capability allows for smooth motor operation, which is crucial for creating intricate designs and complex geometries. Robust current regulation ensures stable performance, even during demanding tasks.

|

Feature |

Description |

|---|---|

|

Microstepping Capability |

Supports microstepping modes for smooth and precise motor control. |

|

Current Regulation |

Features robust current regulation mechanisms for stable motor operation. |

|

Fault Detection |

NFAULT pin provides feedback on fault conditions for diagnostics. |

|

Integrated Protection |

Offers thermal shutdown and overcurrent protection. |

|

Flexible Control |

SLEEP and RST pins allow for sleep mode activation and device reset. |

These features enable users to experiment with advanced designs while maintaining reliability. The DRV8885PWPR empowers 3D printers to handle a wide range of materials and configurations, fostering innovation in the field.

DRV8885PWPR in Robotics

Enhancing Safety and Reliability

Robotic systems demand high levels of safety and reliability to function effectively in critical environments. The DRV8885PWPR incorporates advanced protection mechanisms to meet these requirements. It safeguards against undervoltage, overcurrent, short circuits, and overtemperature conditions. These features prevent damage to motors and other components during fault conditions.

The nFAULT pin provides immediate fault condition feedback, enabling quick diagnostics and resolution. Integrated diagnostics further enhance system reliability by ensuring continuous monitoring of motor performance. These capabilities make the DRV8885PWPR a dependable choice for robotics applications where safety cannot be compromised.

-

Key Safety Features:

-

Undervoltage and overcurrent protection.

-

Short-circuit and thermal shutdown mechanisms.

-

nFAULT pin for rapid fault detection.

-

Boosting Efficiency in Robotic Systems

Efficiency plays a crucial role in robotics, especially in systems requiring continuous operation. The DRV8885PWPR improves efficiency through its low RDS(on) output stage, which minimizes power loss. Its low-power sleep mode reduces energy consumption during idle periods, making it an energy-efficient solution.

Integrated current regulation ensures stable motor operation under varying load conditions. This stability reduces energy waste and enhances the overall performance of robotic systems. By optimizing energy use, the DRV8885PWPR helps reduce operational costs while maintaining high performance.

Enabling Versatility and Adaptability

The DRV8885PWPR supports versatile and adaptable robotic designs. Its microstepping capability allows for smooth and precise motor control, enabling robots to perform intricate movements. Robust current regulation ensures consistent performance, even in demanding tasks.

|

Feature |

Description |

|---|---|

|

Microstepping Capability |

Supports microstepping modes for smooth and precise motor control. |

|

Current Regulation |

Features robust current regulation mechanisms for stable operation. |

|

Fault Detection |

nFAULT pin provides feedback on fault conditions for diagnostics. |

|

Integrated Protection |

Offers thermal shutdown and overcurrent protection. |

|

Flexible Control |

SLEEP and RST pins allow for sleep mode and device reset. |

These features empower robotic systems to adapt to various applications, from industrial automation to medical robotics. The DRV8885PWPR enables engineers to design robots capable of handling diverse tasks with precision and reliability.

Broader Implications of the DRV8885PWPR

Applications in Electric Vehicles

The DRV8885PWPR plays a vital role in electric vehicles (EVs) by enhancing motor control systems. Its ability to drive bipolar stepper motors ensures precise positioning and smooth motion control, which are essential for steering and actuation systems. The device supports high-current and high-voltage operations, making it suitable for demanding EV applications.

In advanced driver assistance systems (ADAS), the DRV8885PWPR contributes to accurate control of actuators. This precision improves the reliability of features like automated steering and braking. The device’s robust current regulation and integrated protection mechanisms ensure stable performance under varying conditions, which is critical for safety in EVs. By optimizing energy efficiency, it also helps reduce power consumption, extending the range of electric vehicles.

Potential for Future Innovations Across Industries

The DRV8885PWPR’s versatility opens doors to innovations across multiple industries. Its support for full-step and up to 1/16 step modes enhances automation systems by enabling fine-tuned motor control. This capability is particularly valuable in industrial automation, where precise positioning and smooth motion are required.

The device’s ability to handle up to 1.5 A full-scale output current makes it suitable for high-performance applications. It can drive motors in printers, scanners, and other consumer electronics, showcasing its adaptability. In robotics, its microstepping capability and robust current regulation enable intricate movements and consistent performance.

Future advancements in automation and control systems could benefit from the DRV8885PWPR’s features. Its design supports innovations in medical robotics, smart home devices, and industrial machinery. By providing reliable and precise motor control, it fosters the development of cutting-edge technologies across diverse sectors.

The DRV8885PWPR revolutionizes 3D printing and robotics by delivering precision, efficiency, and adaptability. Its microstepping capability ensures smooth motor control, while current regulation enhances reliability. The table below highlights its key contributions:

|

Feature/Application |

Description |

|---|---|

|

Microstepping Capability |

Supports smooth and precise motor control, essential for accurate movements. |

|

Current Regulation |

Ensures stable motor operation, enhancing reliability in applications. |

|

Fault Detection |

Provides feedback on fault conditions, aiding in diagnostics. |

|

Integrated Protection |

Includes thermal shutdown and overcurrent protection for safety. |

|

3D Printers |

Ideal for controlling precise movements of stepper motors in 3D printing. |

|

Robotics |

Used for controlling motion in robotic arms and platforms. |

Beyond these fields, the DRV8885PWPR plays a pivotal role in advancing automation and robotics across industries. Its versatility positions it as a cornerstone for future technological innovations, driving progress in automation, medical devices, and electric vehicles

What is the DRV8885PWPR used for?

The DRV8885PWPR is a stepper motor driver designed for precise motor control. It is commonly used in 3D printers, robotics, and industrial automation systems. Its features ensure smooth operation, energy efficiency, and reliability in demanding applications.

How does the DRV8885PWPR improve energy efficiency?

The DRV8885PWPR minimizes power loss with its low RDS(on) output stage. It also includes a low-power sleep mode that conserves energy during idle periods. These features reduce energy consumption and operational costs.

Can the DRV8885PWPR handle high-current applications?

Yes, the DRV8885PWPR supports a full-scale current of 1.5 A and a peak output current of 2.3 A. This capability makes it suitable for high-current applications, such as robotics and electric vehicles.

What safety features does the DRV8885PWPR offer?

The DRV8885PWPR includes thermal shutdown, overcurrent protection, and short-circuit safeguards. The nFAULT pin provides immediate fault feedback, enabling quick diagnostics. These features ensure reliable operation in critical environments.

Is the DRV8885PWPR suitable for advanced designs?

Yes, the DRV8885PWPR supports microstepping modes and robust current regulation. These features enable precise motor control, making it ideal for intricate designs in 3D printing and robotics.

See Also

Harnessing RV1126 For Advanced Robotics Through AI Edge Computing

Integrating AEAT-8800-Q24 To Boost Robotics Efficiency

The Benefits Of Selecting Coilcraft XPL2010 For VRM/VRD

Enhancing Process Control By Unlocking AD74413RBCPZ

Three Key Benefits Of XCF01SVOG20C In Industrial Automation