The drop in the Electric Vehicle Battery Market is transforming industries. In 2023, battery pack prices for electric vehicles fell by almost 14% compared to 2022. This decline occurred because the costs of materials like cobalt, graphite, and manganese decreased. Lower prices make electric vehicles more affordable, allowing more people to purchase them. Additionally, the price gap between NMC and LFP batteries is narrowing, decreasing from 50% higher in 2021 to less than 25% in 2023. This trend illustrates the evolving market.

However, challenges remain. Supply chains are experiencing delays, and global conflicts are causing complications. Despite these issues, electric vehicles are becoming more cost-effective. This shift encourages more individuals to transition to cleaner modes of transportation.

Key Takeaways

-

Electric car battery prices dropped by about 14% in 2023. This makes electric cars cheaper for buyers.

-

There are more batteries available than needed. This causes prices to drop as companies try to sell more.

-

New types of batteries, like solid-state and lithium iron phosphate, work better and cost less.

-

Government money is important to create energy storage systems. These systems help renewable energy and keep power grids steady.

-

Old car companies need to adjust to the EV market. If not, they might lose buyers to newer, creative companies.

Reasons Behind Falling Electric Vehicle Battery Prices

Too Many Batteries in the Market

There are more batteries than needed right now. Reports show that factories are making more lithium-ion batteries than people are buying. For example, by the end of 2023, China could make 2.2 TWh of batteries. But the world only needs 1.2 TWh in 2024. This extra supply has caused prices to drop as companies compete.

In the U.S., battery production doubled from 2022 to 2024, reaching over 200 GWh. Another 700 GWh of factories are being built. But this growth depends on how many electric cars are sold. Sales haven’t grown as fast as production, leaving too many batteries. This has pushed prices even lower.

|

Source |

Key Points |

|---|---|

|

CEA Q2’24 Report |

Too many batteries due to slower EV sales; 18 companies make 85% of them. |

|

BNEF Blog |

China made 2.2 TWh of batteries in 2023, more than needed. |

Slower Growth in Electric Car Sales

Electric car sales are still growing, but not as quickly. In 2022, sales went up by 33%, but in 2023, they only grew by 26%. High prices and few affordable models are part of the problem. Many people still think electric cars are luxury items, especially in the U.S.

Different regions are seeing different trends. China is selling more electric cars quickly, but Europe’s sales have slowed down. This uneven demand makes it hard for companies to plan production. The slower sales growth has added to the problem of too many batteries, which lowers prices even more.

|

Year |

Global EV Sales (Units) |

Growth Rate (%) |

|---|---|---|

|

2022 |

13.9 million |

33 |

|

2023 |

16.7 million |

26 |

Better Battery Technology

New battery technology has made batteries cheaper and better. Solid-state batteries and lithium iron phosphate (LFP) batteries are examples. These new types of batteries last longer, are safer, and store more energy. This has helped lower costs.

For instance, in 2020, the average battery price dropped by 13%, costing $137 per kWh. Big orders, like for the VW ID3, brought prices down to $100 per kWh. Experts at BloombergNEF think battery costs will drop another 20% by 2025, making them even cheaper.

|

Breakthrough Type |

Details |

|---|---|

|

Solid-state batteries |

Store more energy and are safer to use. |

|

Lithium iron phosphate (LFP) |

Safer and lasts longer, often used in electric cars. |

Lower Costs of Battery Parts and Materials

The prices of battery parts and materials have dropped a lot. This has helped make electric cars cheaper for buyers. Important materials like lithium, cobalt, and nickel now cost less. Better mining methods and more recycling have made this possible. These changes have cut down the cost of making batteries.

Scientists are also working hard to improve batteries. They are finding ways to use fewer expensive materials. New designs and better chemistry make batteries work well but cost less. This means companies can make cheaper batteries without losing quality.

Studies show over half of the price drop in lithium-ion batteries comes from research. Better chemistry and materials are key to cutting costs.

Making more batteries at once has also lowered prices. Big factories can make many batteries and save money by spreading costs. In China, factories are growing fast, helping to lower battery prices even more.

All these reasons have made battery packs cheaper. Car companies are now spending more on electric cars. This is speeding up the move to cleaner transportation.

Implications for the Electric Vehicle Market

Automakers Can Make EVs as Cheap as Gas Cars

Cheaper batteries give automakers a chance to make EVs cost the same as gas cars. In the past, expensive lithium-ion batteries made EVs pricey. But battery prices have dropped from $946 per kWh in 2011 to $132 now. Experts say when prices go below $100 per kWh, EVs could cost less than gas cars.

This change might make more people buy EVs since they’ll be affordable. The U.S. Department of Energy says better battery tech and more factories are helping this happen. By 2030, North America could make enough batteries for 13 million EVs each year. Automakers now have a way to price EVs competitively, which could increase sales worldwide.

Small EV Makers Face Big Challenges

Big car companies save money by making lots of EVs, but smaller ones struggle. Supply chain problems and money issues make it hard for small companies to compete. For example, big companies’ low prices hurt smaller brands like VinFast and Polestar, which can’t sell enough cars.

The EV market is getting tougher, and small companies are at risk. Without strong funding or unique ideas, they may lose to bigger brands. To survive, smaller companies need partnerships or government help to stay competitive.

Tariffs and Policies Affect EV Markets

New tariffs and policies are changing the EV market. Some countries, like Indonesia and Australia, cut import taxes to boost EV sales. But others, like Brazil, plan to raise tariffs to 35% by 2026. Canada will add a 100% tariff on Chinese EVs in 2024.

“Tariffs and market changes make things tricky,” said Phoebe O’Hara, energy expert at Fastmarkets.

In the U.S., tariffs on Chinese EVs are now 100%. These rules protect local industries but could slow EV growth worldwide. Automakers must handle these changes carefully to stay competitive globally.

Pressure on Traditional Automakers to Transition to Electric Vehicles

Traditional carmakers are under pressure to switch to electric vehicles (EVs). The fast growth of the EV market forces them to change plans. Companies that don’t adapt could lose customers and investors.

The competition is tough. EV makers like Tesla and BYD lead the market. Older car brands struggle to match their speed and innovation. Many are now spending more on EV development. But high interest rates and car prices slow their progress.

EV sales in the U.S. grew by 52% in 2023. Still, EVs only made up 7.5% of the market, showing slower adoption than expected.

Stock prices add more stress. Many older car companies have seen their stocks drop. This happens because it’s hard to predict how many EVs people will buy. Changing consumer interest in EVs and hybrids makes planning difficult.

|

Evidence Type |

Description |

|---|---|

|

Stock Pressure |

Older carmakers lose stock value due to uncertain EV demand. |

|

Consumer Demand |

Changing EV demand affects company plans and spending. |

|

Competitive Landscape |

Tough competition forces carmakers to focus more on EVs. |

Buyers now want affordable EVs with great features and performance. To meet these needs, companies must spend more on research and production. Those who fail to deliver could fall behind.

Switching to EVs is no longer a choice for traditional carmakers. It’s necessary to survive in a changing industry. Companies that adapt quickly will have a better chance to succeed.

Impact on the Energy Storage Market

Lower Battery Costs Encouraging Energy Storage Use

Falling battery prices are helping more people use energy storage. Lithium-ion batteries are popular because they work well and cost less. In North America, energy storage systems (BESS) are growing fast. This is due to renewable energy use and the need to stabilize power grids. Globally, energy storage system prices dropped 40% in one year. Costs vary by region, with China at $101/kWh, the U.S. at $236/kWh, and Europe at $275/kWh.

The global BESS market could grow from $7.8 billion in 2024 to $25.6 billion by 2029. This growth shows the rising need for renewable energy and better power grids. Cheaper systems make energy storage easier to afford. This helps reduce fossil fuel use and supports cleaner energy goals.

New Technology for Grid and Home Energy Storage

New technology is improving energy storage for grids and homes. Lithium iron phosphate (LFP) batteries are great for grids because they are cheap and store lots of energy. Flow batteries can store energy for up to 30 years without losing performance. A big project in China shows they work well for large-scale use.

Artificial intelligence (AI) helps batteries work better, predicts problems, and manages supplies. New battery types like vanadium flow and sodium-ion improve efficiency and lower costs. These technologies make power grids more reliable and support renewable energy.

Homes also benefit from these advancements. A typical home system of 5-kW/12.5-kWh uses LFP and NMC batteries. It has an 85% efficiency rate. These systems give homeowners backup power and reduce their need for traditional energy.

Government Support for Energy Storage Growth

Government funding is key to building more energy storage systems. Programs like the Energy Storage Demonstration Pilot Grant Program provide $355 million. This money improves power grids, adds renewable energy, and protects important infrastructure. Another program, the Long-Duration Energy Storage Demonstration Initiative, gives $150 million to develop long-lasting storage technologies.

|

Program Name |

Funding Amount |

Purpose |

Uses |

|---|---|---|---|

|

Energy Storage Demonstration Pilot Grant Program |

$355,000,000 |

Supports energy storage projects. |

Improves grids, adds renewable energy, protects infrastructure. |

|

Long-Duration Energy Storage Demonstration Initiative |

$150,000,000 |

Develops long-lasting storage technologies. |

Tests new technologies for commercial use. |

|

Pumped Storage Hydropower Initiative |

$10,000,000 |

Designs pumped storage projects. |

Adds storage capacity and supports renewable energy. |

These programs help make energy storage more common. They also solve problems like modernizing grids and using renewable energy. This leads to a cleaner and more dependable energy future.

Future Innovations in the Electric Vehicle Battery Market

New Types of Batteries (e.g., Lithium-Sulfur, Solid-State)

New batteries like lithium-sulfur and solid-state are changing energy storage. These batteries store more energy, last longer, and are safer than older ones. Solid-state batteries are especially popular because they don’t use liquid electrolytes. This makes them less likely to catch fire and allows for smaller designs.

-

Solid-state batteries are growing fast, with a 34% yearly growth rate.

-

By 2030, 10-15% of EVs might use solid-state batteries.

-

Big investments from carmakers and energy companies are helping this market grow. It could be worth billions by 2030.

Lithium-sulfur batteries also have great potential. They can store more energy than lithium-ion batteries. This makes them perfect for lightweight and long-lasting devices. But problems like short battery life and poor conductivity need fixing before they become common.

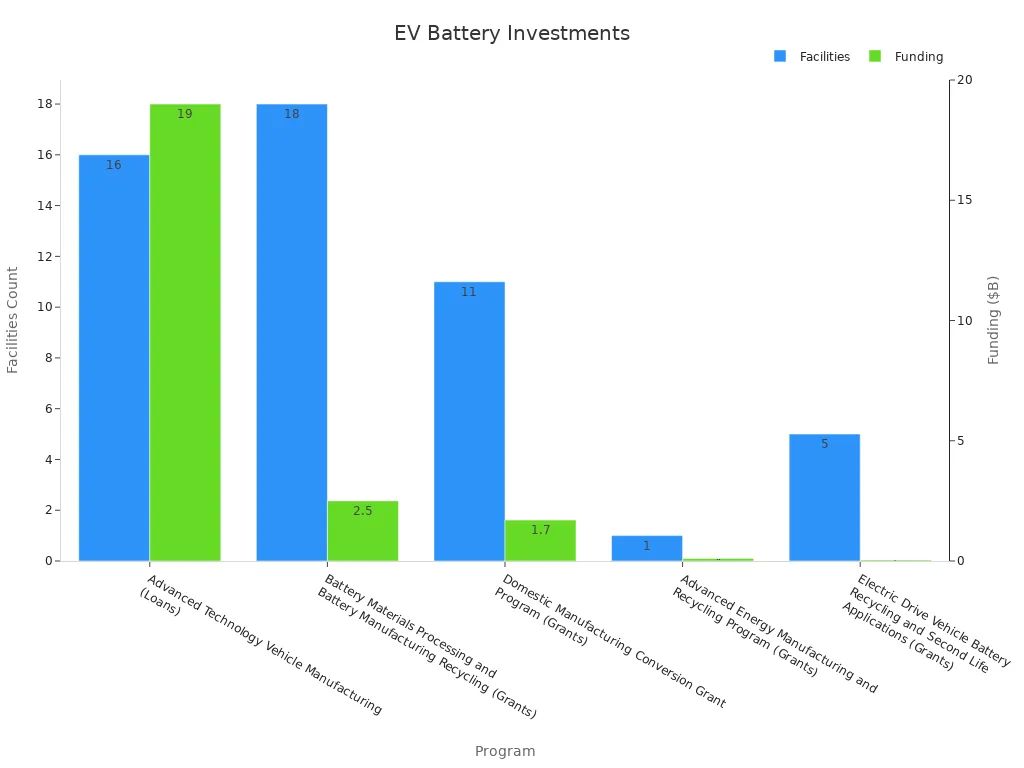

U.S. Spending on Making Batteries Locally

The U.S. is spending a lot to make more batteries at home. Programs like the Infrastructure Investment and Jobs Act (IIJA) and Inflation Reduction Act (IRA) are giving over $23 billion in loans and grants. These programs aim to reduce dependence on other countries and meet the rising demand for EVs.

|

Program |

Number of Facilities |

Funding Given |

|---|---|---|

|

Advanced Technology Vehicle Manufacturing (Loans) |

16 |

$19 billion |

|

Battery Materials Processing and Recycling (Grants) |

18 |

$2.5 billion |

|

Domestic Manufacturing Conversion Grant Program |

11 |

$1.7 billion |

|

Advanced Energy Manufacturing and Recycling Program |

1 |

$100 million |

|

Electric Drive Vehicle Battery Recycling (Grants) |

5 |

$40 million |

For example, $9.2 billion was loaned to BlueOval SK LLC for three battery plants. Another $2 billion went to Redwood Materials for a battery campus in Nevada. These efforts help the U.S. compete in the global battery market.

Silicon and Lithium Metal Anodes

Silicon and lithium metal anodes are exciting new battery parts. Silicon anodes can hold ten times more energy than graphite ones. They also charge faster, making them great for future EVs. But silicon expands when used, which can cause problems over time.

-

Silicon anodes could boost battery energy by 50% in the future.

-

They can reach energy levels of 1000 Wh/l and 400 Wh/kg.

-

Research is working on fixing stability issues for better results.

Lithium metal anodes are also promising, especially in solid-state batteries. They store the most energy and charge quickly. However, they face challenges like forming dendrites and being expensive.

These new battery ideas are helping create better and greener energy solutions for the future.

Problems Growing New Battery Tech During Global Tensions

Making new battery tech grow is tough due to global issues. Lithium, a key material for batteries, is at the center of this problem. China controls over 60% of the world’s lithium refining. This makes other countries depend on China, which complicates plans to find new suppliers.

Countries with lots of lithium, like Australia, Chile, and Argentina, are now important. But political problems in these places make steady supply hard. Some governments limit exports or ask for more money, which messes up global supply chains.

Lithium is very important for clean energy, making things harder. Countries want energy independence, so they compete for lithium and other materials. This competition causes trade fights and rules that slow down new battery tech.

New tech also struggles because of these global problems. Research needs steady access to materials. When supplies are blocked, progress slows. For example, solid-state batteries need rare materials like lithium and cobalt. If these are hard to get, making better batteries takes longer.

The fight over important materials shows why countries must work together. Sharing resources fairly can help keep supplies steady. Without teamwork, clean energy and better batteries will take longer to happen.

Fixing these problems needs teamwork from governments, companies, and scientists. They must find safe and varied sources of materials. Only then can new battery tech grow despite global challenges.

Falling battery prices are changing electric cars and energy storage. Cheaper batteries make EVs easier to buy, boosting their use. But problems remain. Too many batteries are made, and global issues affect supplies. To keep growing, these risks need fixing. Smart spending and better battery designs will lead the way. Governments, carmakers, and scientists must work together. This teamwork can solve problems and help clean energy grow.

Why are electric vehicle battery prices going down?

Battery prices are dropping because of better technology and cheaper materials. Factories are making more batteries, and recycling has improved. These changes help automakers and buyers save money.

How do cheaper batteries affect electric vehicle prices?

Cheaper batteries lower the cost of electric vehicles. Batteries are a big part of an EV’s price. When battery prices fall, carmakers can sell EVs for less. This makes them affordable for more people.

What are solid-state batteries, and why do they matter?

Solid-state batteries use solid parts instead of liquid ones. They are safer, last longer, and store more energy. These features make them great for EVs and energy storage. Experts think they will be very important in the future.

How do governments help energy storage grow?

Governments give money to improve energy storage and power grids. Programs like the Energy Storage Demonstration Pilot Grant fund new ideas. These efforts make energy storage cheaper and better.

Why is lithium important for making batteries?

Lithium is needed for most batteries because it stores energy well. It powers EVs and renewable energy systems. But getting enough lithium is hard due to global supply problems and political issues.

See Also

Ensuring Excellence in Electronics Through Innovative Technology

Explore Essential Automotive Features of FREESCALE MCF5251CVM140

RV1126 Drives AI Edge Computing Solutions for Robotics

Enhancing Automotive Performance Using NXP Microcontrollers MC9S12 Series

Three Key Transformations of Industrial Automation by XCF01SVOG20C