Good cable management is very important for discrete wire assemblies to work well. Following rules and using the right tools can make them last longer and work better. Ignoring these steps can harm cables, cause errors, or stop systems from working. For example, bending wires wrong or using too much force can break them. Using rules like IPC/WHMA-A-620 helps discrete wire assemblies work fast and stay safe.

Strong discrete wire assemblies need good signals and no breaks. Fast cable systems must be handled carefully to avoid damage. By managing cables properly and using the right tools, makers can keep discrete wire assemblies working well and for a long time.

Key Takeaways

-

Good cable organization is important for strong wire setups. Correct paths and lengths stop damage and boost performance.

-

Follow the smallest bend radius to keep wires safe. Don’t make sharp bends, especially near ends, to keep signals clear.

-

Use soft cable ties to hold wires without squeezing them. This stops harm and makes the setup last longer.

-

Check and care for tools often to keep them working well. Clean and fix tools to avoid errors and make better quality.

-

Always pick matching parts from the same brand. This gives better results and lowers the chance of connection problems.

Cable Management Best Practices

Optimize Cable Length and Management

Make sure cables are not too short or too long.

The right cable length is key for good performance. Short cables can pull on connections and cause damage. Long cables can tangle and mess up signals. To get the best length, leave some slack for movement but avoid loops. Testing during design helps find weak spots and ensures cables work well.

Route cables carefully to avoid strain and sharp edges.

Placing cables properly reduces stress and keeps them safe. Sharp edges can harm insulation and cause problems. Neat cables improve airflow and make repairs easier. Use clips and guides to keep cables secure and away from sharp areas. Labeling and color-coding cables help with organization and fixing issues.

Respect Minimum Bend Radius

Follow rules to stop mechanical and electrical problems.

Keeping the right bend radius protects wire assemblies. Tight bends can stress insulation and cause damage. Adding slack to wire harnesses makes them flexible and less likely to break.

Avoid tight bends near ends to protect connections.

Bending wires tightly near ends can weaken them. This can hurt shielding and lower signal quality. Following rules helps wires stay strong and work well over time.

Avoid Sharp Edges and Aggressive Cable Ties

Keep cables away from sharp edges to prevent harm.

Sharp edges can wear down cable insulation. Routing cables safely avoids damage and keeps them reliable. Use grommets or sleeves to protect cables from sharp surfaces.

Use gentle cable ties to avoid crushing cables.

Tight cable ties can squeeze and harm cables. Adjustable ties keep cables secure without too much pressure. Good tools and accessories make wire assemblies last longer.

Tip: Using modern tools like DCIM can help plan cables better and keep systems organized.

Handling and Maintenance

Proper Handling During Modifications

Use the right tools to protect factory-made connections.

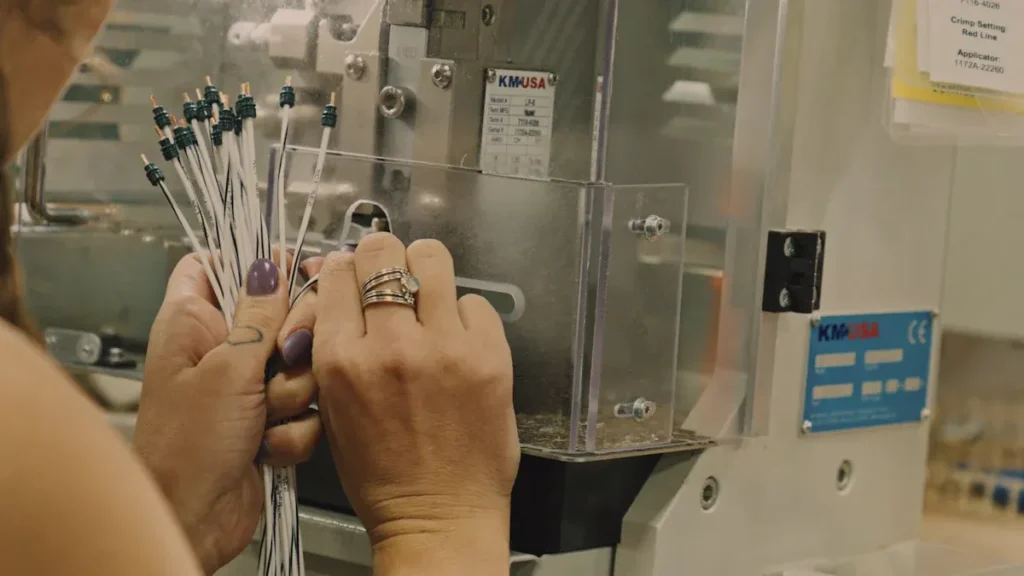

Factory-made connections help wires work well and send signals. Using too much force can break them and cause problems. Workers should handle them gently and with care. Tools like crimping pliers help keep the connections strong and safe.

Note: Taking care of equipment can make it last 20-30% longer. Training programs teach better ways to handle and fix things.

Be gentle with single-ended cables to keep them strong.

Single-ended cables need careful handling to avoid breaking their ends. Pulling or twisting them can make them weak and shorten their life. Using proper tools and following rules keeps them safe. Careful handling also helps prevent signal problems.

|

Key Point |

Description |

|---|---|

|

Proper Handling |

Handle cables gently to keep them working well. |

|

Risk of Damage |

Too much force can harm cable ends, so be careful. |

Handle Retention Features with Care

Do not harm the parts that hold connections in place.

Parts that hold connections are small but very important. If they are bent or forced, they may stop working. Workers should follow rules to keep these parts safe and working well.

-

These small parts keep connections secure and working properly.

-

Rough handling can cause problems and make wires fail.

-

Using the right methods keeps these parts in good shape.

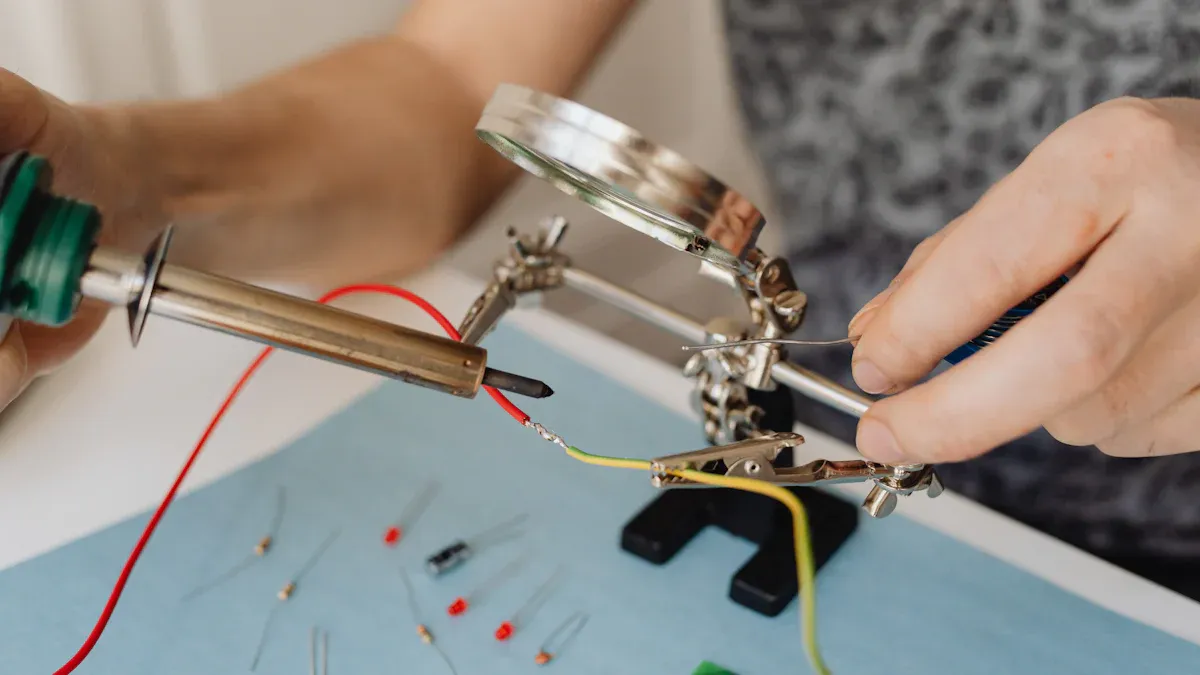

Use correct tools to insert and remove contacts safely.

Putting in or taking out contacts needs care to avoid damage. Special tools make this job easier and safer. These tools help keep the wires working well for a long time.

Use Proper Demating Techniques

Do not pull wires to disconnect them.

Pulling wires to unplug them can break the assembly. Instead, hold the connector and carefully release the latches. This keeps the wires safe and working.

Use special tools or hold the connector to unplug safely.

Tools like ejector shrouds make unplugging easier and safer. They help workers disconnect wires without using too much force. Using these tools protects the assembly and keeps it working longer.

Tip: Safe unplugging methods protect wires and help them last longer. This keeps systems working well over time.

System Compatibility and Tooling

Maintain System Compatibility

Use parts and tools from the same maker for best results.

Using parts and tools from one maker ensures they work well together. Approved tools are made to fit specific parts, avoiding problems. Mixing brands can cause poor connections or less reliable performance. Following rules and using approved tools keeps assemblies strong and dependable.

-

Parts from one maker fit and work better together.

-

Mixing brands can cause weak connections or signal issues.

-

Even if parts seem to fit, they may not work properly.

Avoid using parts from different brands to stop problems.

Using parts from different makers can hurt how assemblies work. Differences in design or materials can cause mismatches. These mismatches may lead to breaks or electrical issues. To avoid this, always use parts and tools from the same brand.

Use the Right Tools for Contact Removal

Use special tools to remove contacts without breaking them.

Special tools help remove contacts safely without causing harm. These tools protect delicate parts and keep crimped connections strong. For example, Samtec suggests tools that make removal safer and more reliable. Using the right tools also avoids future connection problems, keeping assemblies working well.

-

Special tools protect cables and connectors from damage.

-

Good tools lower the chance of assembly mistakes.

-

Keeping tools in good shape ensures they work properly.

Prevent future connection problems by using the right tools.

Wrong tools can harm connectors, causing bad connections and less reliability. Correct tools handle parts carefully, reducing errors. Checking and fixing tools often makes sure they meet quality standards.

Understand Latch Strength Limitations

Know the strength limits of plastic and metal latches.

Plastic and metal latches can only handle so much force. Pulling too hard can break them and ruin connections. In tough jobs, latches alone might not be enough. Stronger latches or screw-downs can keep connections secure.

-

Latches can break under too much stress.

-

Tough jobs need extra ways to secure connections.

-

Knowing latch limits helps keep assemblies working well.

Use strong latches or screws for tough jobs.

For jobs with lots of movement or stress, strong latches work better. Screws add extra security, keeping connections safe in hard conditions. These methods protect signals and make assemblies last longer.

Tip: Check how much stress the job has to pick the right latch.

Inspection and Maintenance

Regularly Maintain and Inspect Tools

Keep crimp tools clean, adjusted, and checked often.

Crimp tools are important for making wire assemblies work well. Cleaning and adjusting them regularly keeps them in good shape. Without care, tools might not work right and cause problems. Adding oil reduces wear, and adjustments make sure they stay accurate.

Check tools often to spot damage or wear early. Predicting problems helps fix tools before they break. This avoids delays and keeps work moving fast. Write down when tools are cleaned or adjusted to track their condition.

-

Checking tools often finds problems like leaks or damage.

-

Keeping records shows what fixes were done and when.

-

Predicting problems stops surprises and makes tools last longer.

Taking care of tools makes them last and work better.

Good care helps tools make better wire assemblies. Clean and adjusted tools give steady results, which is key for strong signals. Checking tools often stops mistakes. For example:

|

Proof |

Reason |

|---|---|

|

Checking tools often keeps quality steady in making wires. |

Without checks, mistakes happen more, showing why checks matter. |

By following a plan to care for tools, makers can keep their wire assemblies working well and meeting rules.

Investigate Issues Thoroughly

Find out why problems happen and fix them.

When something goes wrong, figure out why it happened. Look at tools, wires, and how they’re used to find the issue. Testing parts can show if the problem is with the tools, wires, or how they’re handled. Fixing the cause stops the same problem from happening again.

Keeping notes on changes and test results helps find patterns. These notes show what needs fixing and how to improve. For example, tracking tool adjustments can show when they need tuning.

Write down details about tools, wires, and changes.

Good notes help with fixing and checking tools. Write down when tools are checked, fixed, or changed. A list helps make sure nothing is missed during checks.

-

Notes track when tools are cleaned or fixed.

-

Writing down wire details helps solve problems faster.

-

Lists make checks easier and more reliable.

By checking tools, predicting problems, and keeping good notes, makers can keep their wire assemblies working for a long time.

Good habits help discrete wire assemblies work well and last long. Managing cables, handling them gently, and checking them often improve quality. Using the right tools and following rules stops breaks and keeps signals strong. Fast systems work better with these steps, lowering stress and improving data flow.

Using these methods makes strong assemblies that meet high standards. Makers should focus on these steps to get good results and make assemblies last longer. The right tools and following rules are key for success over time.

What often causes wire assembly problems?

Bad cable management is a common cause of problems. Bending wires too much or sharp edges can harm them. Following good practices keeps wires safe and working well.

Why does system compatibility matter for wire assemblies?

System compatibility makes sure all parts work together smoothly. Using parts that don’t match can cause weak connections and errors. Sticking to one brand avoids these problems.

How often should crimp tools be checked?

Check crimp tools often, ideally before every use. Regular checks keep tools working well and prevent mistakes. Cleaning and adjusting tools helps them last longer.

Why is bend radius important in wire assemblies?

Bend radius affects how long wires last and their signals. Tight bends can damage insulation and cause failures. Following bend rules keeps wires strong and working well.

Can tight cable ties hurt wire assemblies?

Yes, tight cable ties can crush wires and cause damage. Using loose, adjustable ties keeps wires safe and secure without harm.

See Also

Integrating AEAT-8800-Q24 to Boost Robotics Efficiency

The Benefits of Selecting Coilcraft XPL2010 for VRM/VRD

Maintaining Excellence in Electronics Through Advancing Technologies

Three Key Transformations of Industrial Automation by ATIC83E2

Understanding MC9S12DJ256MFUE Specs for Automotive Uses