Film capacitors and DC-link capacitors play a critical role in modern electronics. Film capacitors, constructed using thin plastic films as dielectric materials, are widely known for their reliability and stability. These components excel in applications requiring high-frequency performance and low losses. On the other hand, DC-link capacitors are essential in power electronics. They store and stabilize energy in DC circuits, ensuring smooth operation in systems like renewable energy inverters and industrial drives.

The demand for these capacitors continues to grow. A recent market analysis revealed that the global DC-link film capacitors market, valued at billions in 2022, is projected to expand significantly by 2030, driven by advancements in energy storage and power management technologies.

Key Takeaways

-

Film capacitors use thin plastic layers for steady and reliable performance. They work well in high-frequency tasks.

-

DC-link capacitors keep voltage steady in power systems. They help energy flow smoothly in devices like inverters and motor drives.

-

Picking the right capacitor means checking material quality, voltage limits, and ripple current strength.

-

Film capacitors are great for low energy loss and staying stable in heat. DC-link capacitors manage strong ripple currents well.

-

Knowing how these capacitors differ helps choose the right one for specific electronics.

Film Capacitors

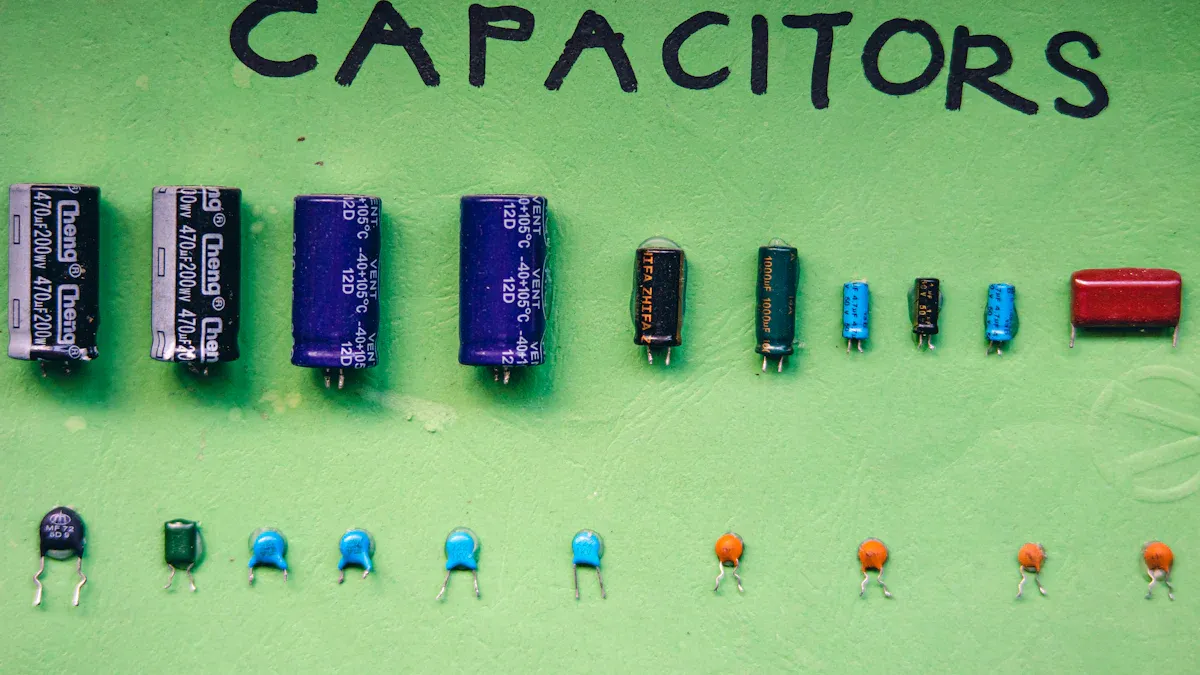

Definition and Construction

Film capacitors are a type of capacitor that uses thin plastic films as the dielectric material. These films are often metallized or combined with metal foils to enhance their electrical properties. The construction involves rolling the film into a cylindrical shape or layering it into a flat stack, depending on the application. Manufacturers design these capacitors to handle both AC and DC voltages, making them versatile components in electronic circuits.

A variety of standards define the construction and specifications of film capacitors. For example, the IEC/EN 60384 series outlines different types of film capacitors based on materials like polyethylene terephthalate (PET), polypropylene (PP), and polyphenylene sulfide (PPS). The table below highlights some common types:

|

Standard Number |

Film Type |

Construction |

Terminals |

Voltage |

Description |

|---|---|---|---|---|---|

|

IEC/EN 60384-2 |

PET |

Metallized |

Leaded |

DC |

Fixed metallized polyethylene-terephthalate film dielectric DC capacitors |

|

IEC/EN 60384-16 |

PP |

Metallized |

Leaded |

DC |

Fixed metallized polypropylene film dielectric DC capacitors |

|

IEC/EN 60384-20 |

PPS |

Metallized |

SMD |

DC |

Fixed metallized polyphenylene sulfide film dielectric surface mount capacitors |

Applications in Electronics

Film capacitors are widely used in various electronic applications due to their reliability and performance. They play a crucial role in power supplies, motor drives, and audio circuits. In renewable energy systems, they stabilize voltage and filter high-frequency noise in inverters for solar panels and wind turbines. Electric vehicles (EVs) also rely on these capacitors for energy buffering and voltage regulation in motor drives.

In addition, film capacitors are essential in industrial equipment. They improve power factor correction (PFC) and protect sensitive components in high-frequency circuits. Their ability to handle high voltages and currents makes them indispensable in power electronics.

Advantages and Benefits

Film capacitors offer several advantages over other capacitor types. They exhibit minimal capacitance change with temperature, unlike ceramic or aluminum electrolytic capacitors, which can vary by more than 10%. This stability ensures consistent performance in varying environmental conditions. Their high insulation resistance and non-polar nature allow them to function effectively in both AC and DC circuits.

These capacitors also have a longer lifespan due to the durability of their dielectric materials. They resist voltage fluctuations, with some models enduring up to 4000 V. Additionally, their low equivalent series resistance (ESR) minimizes energy losses, reducing self-heating under high current conditions. This feature makes them ideal for applications requiring high ripple current handling, such as inverters and motor drives.

Tip: Engineers often choose film capacitors for their reliability and efficiency in demanding applications, particularly in renewable energy and automotive systems.

DC-Link Capacitors

Definition and Role in Power Electronics

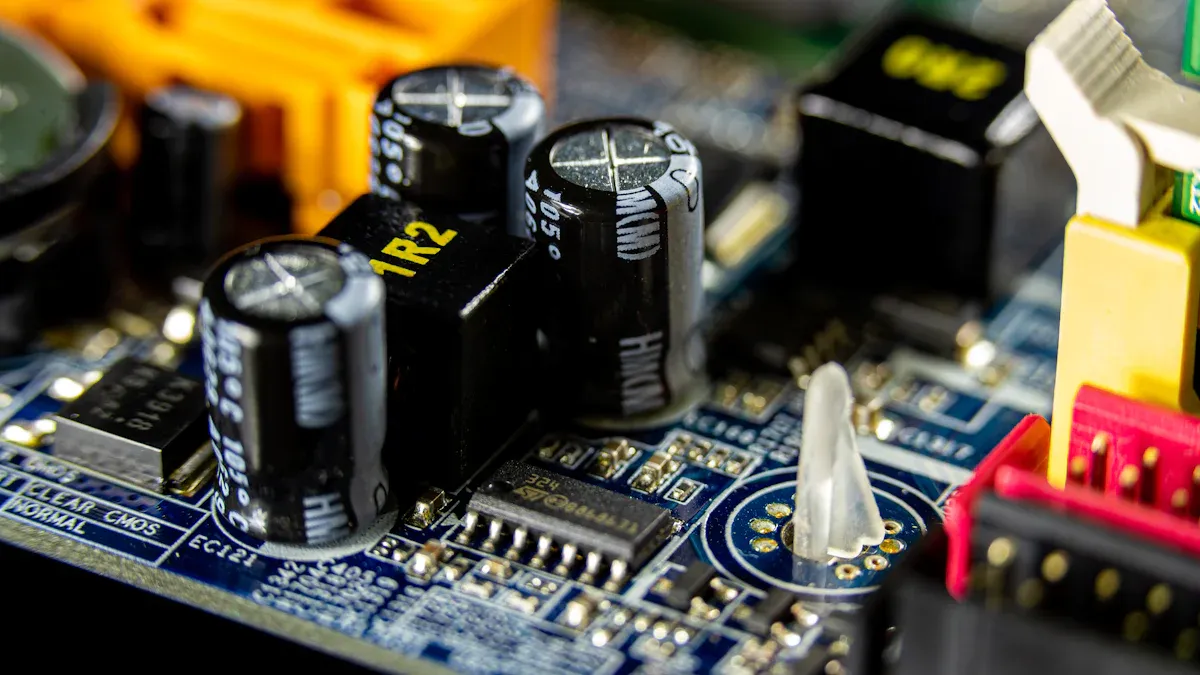

DC-link capacitors are critical components in power electronics. They stabilize DC voltage and manage sudden voltage changes in circuits. These capacitors are commonly used in power converters, inverters, and motor drives. Their primary role is to ensure smooth energy flow between different stages of a system, such as rectifiers and inverters. By absorbing voltage spikes, they protect sensitive components and enhance system reliability.

Technical documents highlight their importance in power electronic converters. They influence the cost, size, and reliability of these systems. Research also emphasizes their role in improving performance through advanced design solutions and monitoring techniques. DC-link capacitors are essential for voltage support, energy storage, and harmonic filtering in high-power applications.

Applications in DC-Link Circuits

DC-link capacitors are widely used in various circuit designs. They stabilize the DC bus voltage and filter high-frequency ripple in DC-AC and AC-DC converters. In renewable energy systems, they play a vital role in solar inverters and wind turbine converters. Electric vehicles rely on these capacitors for energy buffering and voltage regulation in motor drives. They also protect inverters by absorbing voltage spikes during operation.

High current DC link film capacitors are particularly advantageous in high-power applications. Their low equivalent series resistance (ESR) allows them to handle large ripple currents effectively. This feature makes them suitable for industrial motor drives, uninterruptible power supplies (UPS), and battery energy storage systems. Their durability and high DC voltage rating further enhance their performance in demanding environments.

Advantages and Key Features

DC-link capacitors offer several advantages over traditional electrolytic capacitors. They provide a longer service life, higher breakdown voltage, and better resistance to high temperatures. Their ability to handle larger ripple currents makes them ideal for high-power applications. These capacitors also exhibit superior thermal stability, ensuring consistent performance under varying conditions.

In smart grid applications, the lifetime of DC-link capacitors is crucial. Their quantity can reach tens of thousands, requiring thorough evaluation of thermal stress effects. Compared to other capacitor types, DC-link capacitors deliver enhanced reliability and efficiency. Their self-healing properties and robust construction contribute to their widespread adoption in modern power electronics.

Comparing Film Capacitors and DC-Link Capacitors

Differences in Construction

Film capacitors and DC-link capacitors differ significantly in their construction. Film capacitors typically use a single metallized plastic film, often polypropylene (PP), as the dielectric material. This design provides a lightweight and compact structure suitable for general-purpose applications. In contrast, DC-link capacitors employ a double metallized film, often with polyethylene terephthalate (PET) as the base material. This dual-layer construction enhances stability and performance under high-power conditions.

The table below highlights key construction differences:

|

Feature |

R75H (Film Capacitor) |

R76H (DC-Link Capacitor) |

|---|---|---|

|

Construction Type |

Single metallized film with PP base |

Double metallized film with PET base |

|

Capacitance Stability |

Slightly decreases at high temperatures |

More stable due to double layers |

|

Temperature Tolerance |

Up to 135°C |

|

|

Frequency Response |

Limited at higher frequencies |

Better performance at high frequencies |

|

Shrinkage Effect |

Higher due to single layer |

Lower due to double layer |

|

Application |

General use |

Critical in power converters |

This comparison demonstrates how construction influences the performance and suitability of these capacitors for specific applications.

Differences in Functionality

The functionality of film capacitors and DC-link capacitors also varies based on their design and intended use. Film capacitors excel in applications requiring high-frequency performance and low energy losses. Their ability to self-heal after dielectric breakdown makes them reliable in circuits prone to voltage stress. Studies show that film capacitors can replace electrolytic capacitors in DC bus applications, offering improved reliability and lifespan.

DC-link capacitors, on the other hand, are optimized for power electronics. They stabilize DC voltage and filter high-frequency ripple in circuits. Their robust design allows them to handle high ripple currents and sudden voltage changes effectively. These capacitors also provide better thermal stability, ensuring consistent performance in demanding environments.

Note: Film capacitors are ideal for high-frequency circuits, while DC-link capacitors are better suited for high-power applications requiring voltage stabilization.

Typical Use Cases

Film capacitors and DC-link capacitors serve distinct purposes in various industries. Film capacitors are commonly used in power converters for renewable energy systems like solar and wind. They also play a vital role in heavy-duty motor drives and hybrid automotive systems. Their low Equivalent Series Resistance (ESR) enhances ripple current ratings, making them suitable for high-frequency applications.

DC-link capacitors are critical in power converters and inverters for industrial motor drives and uninterruptible power supplies (UPS). They handle high ripple currents and provide energy buffering in electric vehicles. Their longer lifespan and higher capacitance values make them indispensable in battery energy storage systems and smart grids.

Tip: Engineers often choose film capacitors for their self-healing properties and DC-link capacitors for their durability in high-power circuits.

Selecting the Right Capacitor

Key Factors to Consider

Choosing the right capacitor for an application requires careful evaluation of several critical factors. These considerations ensure optimal performance, reliability, and longevity in electronic systems. Below are the key factors to keep in mind:

-

Material Quality: High-quality capacitors use superior dielectric materials and conductive elements. This enhances their performance and extends their lifespan, especially in demanding environments.

-

Ripple Current Capability: Ripple current is a crucial parameter for capacitors in power electronics. A proper dc link capacitor must handle high ripple currents without overheating or degrading over time.

-

Voltage Rating: The capacitor’s voltage rating must exceed the maximum operating voltage of the circuit. This prevents breakdowns and ensures safe operation.

-

Equivalent Series Resistance (ESR): Low ESR minimizes energy losses and reduces heat generation. This is particularly important for film capacitors used in high-frequency applications.

-

Thermal Stability: Capacitors should maintain consistent performance across a wide temperature range. This is vital for applications like renewable energy systems and electric vehicles.

-

Manufacturing Precision: Precise manufacturing processes ensure that capacitors meet performance metrics and withstand rated conditions. This reduces the likelihood of premature failure.

-

Quality Control: Stringent quality control procedures result in reliable components. Capacitors subjected to rigorous testing are less prone to defects and failures.

Tip: Engineers should prioritize capacitors with self-healing properties and robust construction for high-demand applications. These features enhance reliability and reduce maintenance costs.

Practical Selection Tips

Selecting the proper dc link capacitor or film capacitor involves more than just understanding technical specifications. Practical insights and real-world testing can guide engineers toward the best choice for their specific needs. Here are some actionable tips:

-

Evaluate Application Requirements: Identify the specific role of the capacitor in the circuit. For example, DC-link capacitors stabilize voltage and filter ripple in power converters, while film capacitors excel in high-frequency circuits.

-

Compare Performance Metrics: Use laboratory test results to compare capacitance, voltage rating, ripple current, and ESR. The table below illustrates how film capacitors and aluminum electrolytic capacitors differ in key parameters:

Capacitor Type

Capacitance

Voltage Rating

Ripple Current

ESR (Total)

Dissipation (at 50A rms)

Film Capacitors (4x 20µF)

80µF

700V

62.5A rms

< 1 mΩ

< 4 W

AL-Electrolytic (10x 2700µF)

27000µF

400V

85A rms

~ 8 mΩ

~ 20 W

-

Consider Environmental Conditions: Choose capacitors designed to withstand the operating environment. For instance, high-temperature tolerance is essential for automotive and industrial applications.

-

Review Manufacturer Specifications: Consult technical guidelines and white papers from reputable manufacturers. These resources often include strategies for selecting capacitors based on application needs. For example:

-

Strategies for evaluating ripple current capability.

-

Checklists for capacitor replacements in specific applications.

-

Test in Real-World Scenarios: Conduct practical tests to validate the capacitor’s performance under actual operating conditions. This ensures compatibility and reliability in the intended application.

Note: Engineers should always verify that the selected capacitor meets or exceeds the circuit’s voltage, current, and thermal requirements. This prevents failures and ensures long-term performance.

Film capacitors and DC-link capacitors serve distinct yet complementary roles in modern electronics. Film capacitors excel in high-frequency circuits, offering reliability and low energy losses. DC-link capacitors, on the other hand, stabilize voltage and manage ripple currents in high-power applications. Their advanced dielectric materials enhance thermal resilience and extend service life, making them indispensable in industries like renewable energy and automotive systems.

Understanding their differences is crucial for optimal selection. For instance, DC-link capacitors outperform others in ripple current tolerance, as shown below:

|

Capacitor Type |

Ripple Factor (RF) under 100 kHz |

Performance Comparison |

|---|---|---|

|

p-HEEC1/2 |

1.33% (sinusoidal) |

Superior to AEC, comparable to film types |

|

AEC |

4.20% (sinusoidal) |

Baseline for comparison |

Selecting the right capacitor ensures efficiency, reliability, and long-term performance in demanding applications.

What are the main differences between film capacitors and DC-link capacitors?

Film capacitors are ideal for high-frequency circuits, while DC-link capacitors excel in high-power applications. Film capacitors use a single metallized plastic film, whereas DC-link capacitors often feature double metallized layers for enhanced durability and performance under high-power conditions.

Why are DC-link capacitors important in power electronics?

DC-link capacitors stabilize DC voltage and filter high-frequency ripple in circuits. They protect sensitive components from voltage spikes and ensure smooth energy flow in systems like inverters, motor drives, and renewable energy converters.

How do film capacitors improve circuit performance?

Film capacitors offer high reliability, low energy losses, and excellent temperature stability. Their low equivalent series resistance (ESR) minimizes heat generation, making them suitable for high-frequency applications like power supplies, audio circuits, and renewable energy systems.

What factors should engineers consider when selecting capacitors?

Engineers should evaluate material quality, voltage rating, ripple current capability, and thermal stability. They should also consider the capacitor’s application, environmental conditions, and manufacturer specifications to ensure optimal performance and reliability.

Can film capacitors replace electrolytic capacitors?

Film capacitors can replace electrolytic capacitors in some applications, especially where high reliability and long lifespan are required. However, they may not match the capacitance levels of electrolytic capacitors in high-capacitance, low-frequency circuits.

See Also

Understanding The IRF820 N-Channel MOSFET For Power Applications

Three Key Features Of The SPC5605BMLL6 And SPC5607BMLL6 ECUs

A Deep Dive Into MC9S12DJ256MFUE Specs For Vehicles

Highlighting Three Key Features Of R5F64219JFB Audio Devices

Unveiling The LPQ252-CEF For Optimal Power Efficiency