|

Hitachi |

LNC 500 |

Hitachi |

LPF 602A |

|

Hitachi |

LPU 500 |

Hitachi |

LYA210A |

|

Hitachi |

LFI 500 |

Hitachi |

LYA010A |

|

Hitachi |

LSU500 |

Hitachi |

LPA302A2 |

|

Hitachi |

LPE510 |

Hitachi |

LYD000A |

|

Hitachi |

LPF500 |

Hitachi |

LYD105A |

|

Hitachi |

LPF610A |

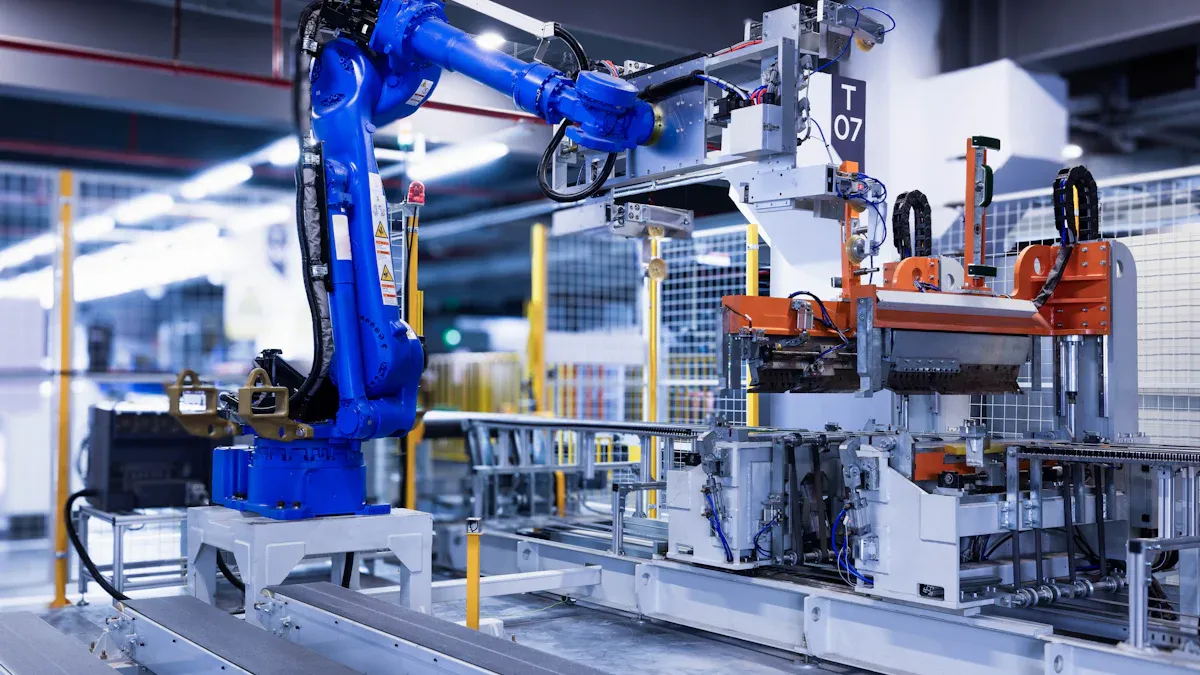

Modern manufacturing faces increasing demands for efficiency, precision, and adaptability. Traditional automation solutions often fall short, creating a critical need for advanced technologies. The HITACHI LYD000A module emerges as a pivotal innovation directly addressing these challenges. This blog explores how this HITACHI LYD000A module is fundamentally transforming production lines. It also drives the next generation of manufacturing automation. The HITACHI module supply ensures reliable operation.

Key Takeaways

-

The HITACHI LYD000A module is a key part of modern factories. It helps machines work better.

-

This module makes factory work more exact. It helps machines do tasks with high accuracy.

-

The module collects data fast. This helps factories fix problems before they happen.

-

It connects easily with other factory machines. This makes the whole factory work together smoothly.

-

The HITACHI LYD000A module helps factories make more products. It also makes products better and saves money.

I. The HITACHI LYD000A Module: Core Automation Component

A. What is the HITACHI LYD000A Module?

The HITACHI LYD000A module stands as a foundational element in modern industrial automation. It functions as a versatile Digital Input Module, precisely receiving and interpreting signals from various sensors and switches on the production floor. Beyond simple input, it also serves as a robust Process Control Module, directly managing and regulating complex manufacturing operations. Furthermore, the module integrates an AC Drive Inverter, allowing it to control the speed and torque of motors with high accuracy. This multi-functional design makes the HITACHI LYD000A module a central nervous system for automated processes.

B. Key Technical Specifications and Features

The HITACHI LYD000A module boasts impressive technical specifications that enable its advanced capabilities. It features substantial processing power, which allows for rapid data analysis and quick decision-making in real-time. The module offers diverse connectivity options, including Ethernet/IP, PROFINET, and Modbus TCP, ensuring seamless communication within existing industrial networks. Its extensive I/O capabilities support a wide range of sensors and actuators, providing flexibility for various applications. A notable design feature is its unique three-in-one power supply casing, which incorporates conduction cooling. This innovative cooling method enhances reliability and extends the module’s operational lifespan, even in demanding industrial environments.

C. LYD000A’s Unique Advantages

The HITACHI LYD000A module offers distinct advantages over previous generations and competing solutions. Its integrated design, combining digital input, process control, and AC drive inversion into a single unit, simplifies system architecture and reduces installation complexity. This consolidation also leads to a smaller footprint, saving valuable space on the factory floor. The conduction cooling system provides superior thermal management compared to traditional fan-based cooling, reducing maintenance needs and improving overall system uptime. This robust design ensures consistent performance and reliability, making it a highly efficient and cost-effective choice for manufacturers seeking to upgrade their automation infrastructure.

II. LYD000A Capabilities: Elevating Manufacturing

The HITACHI LYD000A module significantly elevates manufacturing capabilities. It brings advanced features to production lines.

A. Enhanced Precision and Control

The HITACHI LYD000A module significantly enhances precision and control. It fine-unes machine operations. This reduces errors in manufacturing processes. For example, the module precisely controls robotic arms. This ensures accurate component placement during assembly. It also improves quality inspection systems. The module helps these systems detect even tiny defects. This leads to higher product quality.

B. Real-time Data Processing and Analytics

The module excels at real-time data processing and analytics. It collects data from sensors instantly. It then processes this information without delay. This immediate data transmission impacts predictive maintenance. Factories can identify potential equipment failures before they happen. The module also provides valuable operational insights. This helps managers understand production line performance. They can make quick, informed decisions.

C. Seamless Integration and Interoperability

The module offers seamless integration and interoperability. It connects easily with existing industrial equipment. This includes Programmable Logic Controllers (PLCs) and SCADA systems. The module supports open standards and common communication protocols. These protocols include Ethernet/IP and Modbus TCP. This ensures smooth data exchange across different systems. This connectivity creates a unified and efficient manufacturing environment.

III. Practical Applications: LYD000A Across Industries

The HITACHI LYD000A module finds diverse applications across many industrial sectors. Its adaptability makes it a valuable tool for modern manufacturing.

A. Automotive Manufacturing Use Cases

In automotive manufacturing, the module drives assembly line automation. It precisely controls robotic arms for welding and painting car bodies. It also manages the installation of various components. This ensures consistent quality and faster production cycles. The module also plays a key role in quality control. It helps automated systems inspect parts for flaws. This reduces errors and improves vehicle reliability.

B. Electronics Production Use Cases

Electronics production demands extreme precision. The module excels in this environment. It enables precision component placement on circuit boards. This is crucial for miniaturized devices. It also automates the testing of electronic components and finished products. This ensures every device meets strict performance standards. Manufacturers achieve high throughput and minimal defects.

C. Food and Beverage Processing Use Cases

The food and beverage industry relies on strict process control. The module manages critical steps like mixing ingredients and maintaining specific temperatures. It also automates packaging processes. This includes filling bottles, sealing containers, and applying labels. These applications ensure product consistency, safety, and efficient production.

D. Building Automation and Other Sectors

Beyond traditional manufacturing, the module contributes to building automation. It manages lighting, heating, and ventilation systems. This improves energy efficiency and occupant comfort. In pharmaceuticals, it controls precise dosage and monitors sterile environments. Heavy machinery industries use it to operate large equipment and monitor performance. This versatility highlights its broad impact on various industrial operations.

IV. Tangible Benefits: Impact on Production Lines

The integration of advanced automation components like the HITACHI LYD000A module brings significant, measurable advantages to manufacturing operations. These benefits directly improve a company’s bottom line and competitive standing.

A. Increased Efficiency and Throughput

Manufacturers experience a notable boost in efficiency and throughput. The module’s precise control capabilities reduce cycle times for individual tasks. Machines complete operations faster and more accurately. This means production lines move products through each stage at an accelerated pace. Furthermore, the system optimizes resource utilization. It manages energy consumption effectively. It also minimizes material waste during production. This leads to a higher volume of finished goods produced in the same amount of time.

B. Improved Product Quality and Consistency

The module plays a crucial role in elevating product quality and consistency. It minimizes defects by ensuring machines perform tasks with extreme accuracy. Automated processes follow exact specifications every time. This reduces the chance of human error. Products meet stringent quality standards consistently. This reliability builds customer trust and reduces costly recalls or rework.

C. Cost Reduction and ROI

Implementing advanced automation leads to substantial cost reductions and a strong Return on Investment (ROI). Lower operational costs result from optimized energy use and reduced labor needs for repetitive tasks. The system also cuts down on waste materials due to fewer errors and more efficient processes. A faster time to market for new products also contributes to financial gains. Companies can introduce innovations quicker, capturing market share ahead of competitors. These combined factors ensure a rapid and significant return on the initial investment.

D. Enhanced Safety and Reliability

The module significantly enhances safety and overall system reliability. It automates hazardous tasks, removing human workers from dangerous environments. This protects employees from potential injuries. The system also reduces human error in critical operations. This makes the entire production line more dependable. Fewer unexpected shutdowns occur. Equipment operates more consistently, leading to a safer and more reliable manufacturing environment.

V. The Future of Manufacturing with the HITACHI LYD000A Module

A. Role in Industry 4.0 and Smart Factories

The HITACHI LYD000A module plays a crucial role in the evolution of Industry 4.0 and smart factories. It acts as a foundational component within these advanced manufacturing ecosystems. The module facilitates seamless communication between machines, sensors, and central control systems. This connectivity creates a network of intelligent devices. Factories gain the ability to monitor and control production processes remotely. They can also make real-time adjustments. This integration helps factories achieve higher levels of automation and efficiency. It moves manufacturing towards a truly interconnected and intelligent future.

B. Potential for AI/ML Integration

The module’s robust data processing capabilities open doors for advanced AI and Machine Learning (ML) integration. It collects vast amounts of operational data. This data feeds AI algorithms. These algorithms can analyze patterns and predict potential issues. For example, AI can forecast equipment failures before they occur. This enables predictive maintenance. ML models can also optimize production parameters. They learn from past performance to improve efficiency. This integration transforms raw data into actionable insights. It drives continuous improvement in manufacturing operations.

C. Scalability for Future Challenges

The HITACHI LYD000A module offers significant scalability for future manufacturing challenges. Its modular design allows for easy expansion and adaptation. Manufacturers can add more modules as their production needs grow. The system integrates new technologies without major overhauls. This adaptability ensures that factories remain agile. They can respond quickly to market changes and technological advancements. The module’s robust architecture supports evolving demands. It provides a future-proof solution for dynamic industrial environments.

The HITACHI LYD000A module revolutionizes manufacturing automation. Its precision, data capabilities, and seamless integration drive unparalleled efficiency, quality, and cost savings. Businesses gain a strategic investment. This module future-proofs operations and provides a competitive edge. Explore how it can transform your specific production challenges.

FAQ

What is the main purpose of the HITACHI LYD000A module?

The HITACHI LYD000A module serves as a core automation component. It functions as a Digital Input Module, a Process Control Module, and an AC Drive Inverter. This multi-functional design helps manage and regulate complex manufacturing operations effectively.

How does the LYD000A improve production line efficiency?

The LYD000A enhances efficiency through precise control and real-time data processing. It reduces cycle times and optimizes resource use. This leads to higher throughput and faster production. The module also minimizes errors, which saves time and materials.

Can the HITACHI LYD000A integrate with existing factory equipment?

Yes, the LYD000A offers seamless integration. It connects easily with existing PLCs and SCADA systems. The module supports common communication protocols like Ethernet/IP. This ensures smooth data exchange across different industrial equipment.

Which industries benefit from using the LYD000A module?

Many industries benefit from the LYD000A module. These include automotive, electronics, and food and beverage processing. It also finds use in building automation and pharmaceuticals. Its versatility makes it valuable across diverse manufacturing and operational environments.

What role does the LYD000A play in smart factories?

The LYD000A is crucial for Industry 4.0 and smart factories. It enables seamless communication between machines and central systems. This connectivity supports remote monitoring and real-time adjustments. It helps create intelligent, interconnected manufacturing ecosystems.

See Also

Revolutionizing Industrial Automation: Three Key Impacts of XCF01SVOG20C Technology

Integrating AEAT-8800-Q24: Boosting Robotics Performance Through Seamless Implementation Strategies

ATIC83E2’s Role in Industrial Automation: Exploring Its Core with Practical Applications

Optimizing Process Control: Harnessing the Full Potential of AD74413RBCPZ

ARTESYN NPT42-M: Essential Power Solutions for Advanced Industrial Automation Systems