The HVC50 for high-power systems with up to 750 A at 1500 V enhances megawatt charging systems with exceptional performance and reliability. It can manage very high power demands, such as interrupting direct current voltages up to 1500 V and handling currents as high as 1000 A in a single operation. Additionally, it can operate continuously with up to 750 A without any issues, while its steady power consumption is only 6 W, making it highly energy-efficient.

Designed for vehicles and industrial applications, the HVC50 addresses challenges related to power usage, reliability, and scalability. Its advanced features make it a vital component for clean energy systems, facilitating industries’ transition to greener alternatives. TDK products, including the HVC50, which operates with up to 750 A at 1500 V, play a crucial role in developing larger and more efficient megawatt charging systems.

Key Takeaways

-

The HVC50 handles high power, working up to 750 A at 1500 V. This makes it perfect for megawatt charging systems.

-

Its two-coil design uses only 6 W of energy. This saves power and helps support clean energy goals.

-

The gas-filled ceramic arc chamber improves safety. It quickly stops current to protect the system from problems.

-

The HVC50’s modular design makes upgrades simple. This helps it adjust to future energy needs.

-

It meets global safety rules like CE and UL. This ensures the HVC50 is safe and works well in many uses.

Challenges in Megawatt Charging Systems

Power efficiency in high-power systems

Managing power efficiency in high-power systems is tough. These systems must supply huge energy amounts for fast charging. Long-haul electric trucks need over 1 MW of power to charge in under 30 minutes. But, energy transfer problems can waste power and raise costs.

A study shows how hard it is to measure power efficiency. Below is a table explaining some key challenges:

|

Challenge Type |

Description |

|---|---|

|

Scale of ML Systems |

MLPerf Power benchmarks range from tiny to massive, making it hard to measure all systems the same way. |

|

Datacenter Training / HPC |

Measuring total power means including all parts, like cooling systems, which complicates standard methods. |

|

Edge Systems |

Edge devices use different amounts of power, needing special tools to measure accurately. |

|

Tiny Embedded ML Systems |

Measuring very low power needs precise tools to avoid mistakes. |

|

Heterogeneity in Hardware |

Different hardware types need flexible methods to compare power use fairly. |

|

Myths in Power Measurement |

Some think measuring one part’s power is enough, but full system power matters most. |

Fixing these issues helps save energy and cut waste, making high-power systems work better.

Reliability under extreme conditions

High-power systems must stay reliable in tough conditions. They need to handle heat, humidity, and bad weather. For example, hot temperatures can cause overheating. Humidity might harm parts inside. Snow and ice can rust parts, leading to electrical problems.

Here’s a table of common reliability problems:

|

Reliability Issue |

Description |

|---|---|

|

Sensitivity to temperature, humidity |

Heat can overheat systems; humidity can damage internal parts. |

|

Corrosion due to harsh weather |

Snow, ice, and moisture can rust parts, causing electrical failures. |

|

Insufficient Testing Protocols |

Not testing real-world conditions can miss problems; limited testing can cause errors. |

To improve reliability, systems need strong testing and durable materials. This reduces downtime and boosts performance for megawatt charging systems.

Scalability for future energy demands

Scalability is key as energy needs grow. Systems must handle bigger electricity loads and new technologies. For example, the dsgrid toolkit helps model and predict electricity use. It shows current and future energy needs.

The Electrification Futures Study used the dsgrid toolkit to study electricity use in U.S. counties. It showed how electrification affects energy use and why scalable systems are needed. Scalable charging stations are vital for electric cars and other tech.

Focusing on scalability keeps megawatt charging systems ready for growing energy demands.

Integration with existing infrastructure

Connecting megawatt charging systems to current setups is tricky. It requires making sure systems work together while staying reliable and efficient. This often means solving problems with software, designs, and managing resources.

Common Challenges in Integration

Adding new systems can bring many problems, such as:

-

Not enough trained workers to handle the setup process.

-

Limited budgets that stop hiring experts or buying tools.

-

Poor tracking of systems, making it hard to find issues.

-

Bad setup choices that waste resources and lower efficiency.

Data problems can also make things harder. For example:

-

Missing or wrong data can mess up operations.

-

Too much data can overload the system.

-

Repeated data can cause matching errors.

Examples of Integration Challenges

Here’s a table showing common problems and examples:

|

Problem Type |

Examples |

|---|---|

|

Weak or missing software platforms |

Systems become unreliable |

|

Design mistakes |

Slowdowns or single failure points |

|

No support for different transfer methods |

Systems don’t work well together |

|

Poor tracking of system performance |

Hard to spot and fix problems |

|

Bad setup choices |

Wastes resources and lowers efficiency |

|

Overuse of resources |

Raises costs |

Solving Integration Problems

To connect megawatt charging systems successfully, plan carefully. Check your current setup for weak spots and areas to improve. Use strong and flexible parts like the HVC50 for better compatibility and reliability. Its design makes it easy to adjust for future needs, avoiding problems later.

Train your team to handle technical issues. Skilled workers can solve problems and improve system performance. Fixing these challenges helps create smooth connections and supports the need for clean energy solutions.

HVC50 for High-Power Systems with up to 750 A at 1500 V

Advanced power management capabilities

The HVC50 is great for managing high-power systems. It works with up to 750 A and 1500 V DC. This makes it perfect for modern battery charging needs. It handles big energy demands while staying reliable and efficient.

One special feature is its fast switching speed. It stops arcs in just 1.2 milliseconds. This saves energy and boosts performance. Its design also keeps contacts cooler, which helps the system last longer. Plus, it creates less electromagnetic interference (EMI), so nearby devices work smoothly.

Here’s a simple table showing its key features:

|

Metric |

Value |

|---|---|

|

Maximum Current Capability |

750 A |

|

Maximum Operating Voltage |

1500 V DC |

|

Switching Speed |

Stops arcs in 1.2 ms |

|

Reliability |

Very high |

|

Mechanical Switching Cycles |

More durable |

|

Heat Generation on Contacts |

Reduced |

|

EMI Generation |

Lower |

These features make the HVC50 a top choice for high-power charging systems.

Gas-filled ceramic arc chamber for safety

Safety is very important in high-voltage systems. The HVC50 has a gas-filled ceramic arc chamber to keep it safe. This feature quickly disconnects current, even in tough conditions. Its sealed design ensures it works well for a long time.

The mirror contact adds extra safety by giving accurate switching feedback. It meets global safety rules like IEC 60947-4-1 standards. This makes it great for energy storage and battery charging systems.

Key safety benefits include:

-

Quick and safe current disconnection in tough conditions.

-

Sealed design for long-lasting use.

-

Meets global safety standards for better protection.

These safety features keep your system safe and running smoothly.

Dual-coil design for energy efficiency

The HVC50 has a dual-coil design that saves energy. It works with 12 V or 24 V systems. After turning on, one coil shuts off in 200 milliseconds. This lowers power use to just 6 W, saving energy and improving performance.

This design also helps reduce costs and supports green energy goals. Its small size and light weight make it easy to fit into different systems.

The dual-coil design ensures steady performance in many uses. Whether for energy storage or charging stations, it helps you get the best results.

Compliance with global safety standards

Safety is very important in high-power systems like megawatt charging. Components must follow strict global safety rules to work safely. The HVC50 meets these rules with certifications like CE, UKCA, and UL. These prove it is safe and reliable for use in Europe, the U.S., and Asia.

Why Global Safety Standards Matter

Global safety rules are important for many reasons:

-

Protecting Users and Equipment: High-voltage systems can be dangerous. Certified parts like the HVC50 lower accident risks by working safely in tough conditions.

-

Ensuring Compatibility: Standards help parts work well with other systems anywhere.

-

Building Trust: Certifications show the product was tested and approved by experts.

Tip: Look for labels like CE, UKCA, or UL when picking parts for high-power systems. These show the product meets global safety rules.

Key Safety Features of the HVC50

The HVC50 has special safety features that meet global rules. Here’s how it stays safe and reliable:

-

Gas-Filled Ceramic Arc Chamber: This helps the HVC50 stop high currents quickly and safely, even in hard conditions.

-

Mirror Contacts: These give accurate switching feedback, making it safer and reducing electrical problems.

-

Sealed Design: The sealed build keeps dust, water, and dirt out, making it last longer.

|

Certification |

Region |

Purpose |

|---|---|---|

|

CE |

Europe |

Proves it meets European safety and environmental rules. |

|

UKCA |

United Kingdom |

Shows it follows UK safety and performance standards. |

|

UL |

United States |

Confirms it meets U.S. safety and quality rules. |

How Compliance Benefits You

Using certified parts like the HVC50 gives you many benefits:

-

Peace of Mind: You know the system will work safely and well.

-

Simplified Integration: Certified parts fit easily into current systems.

-

Future-Proofing: Following global rules keeps your system ready for future changes.

The HVC50’s global safety compliance makes it a great choice for megawatt charging systems. It protects your system and helps support clean energy goals.

Charging Solutions with HVC50

Two-way energy flow for charging and discharging

The HVC50 lets energy flow both ways. It works for charging batteries and sending stored energy back to the grid. This makes it useful for many high-power systems. It handles up to 750 A at 1500 V, making it great for modern battery setups like megawatt charging stations.

This two-way feature also helps energy storage systems. It smoothly switches between charging and discharging modes. This keeps batteries working efficiently, saving energy and improving performance. The HVC50 gives you more flexibility and reliability for managing power needs.

Better heat control for lasting performance

Controlling heat is important for keeping systems working well. The HVC50 has advanced features to manage heat. It cools the system during heavy use, preventing overheating. This helps batteries and parts last longer.

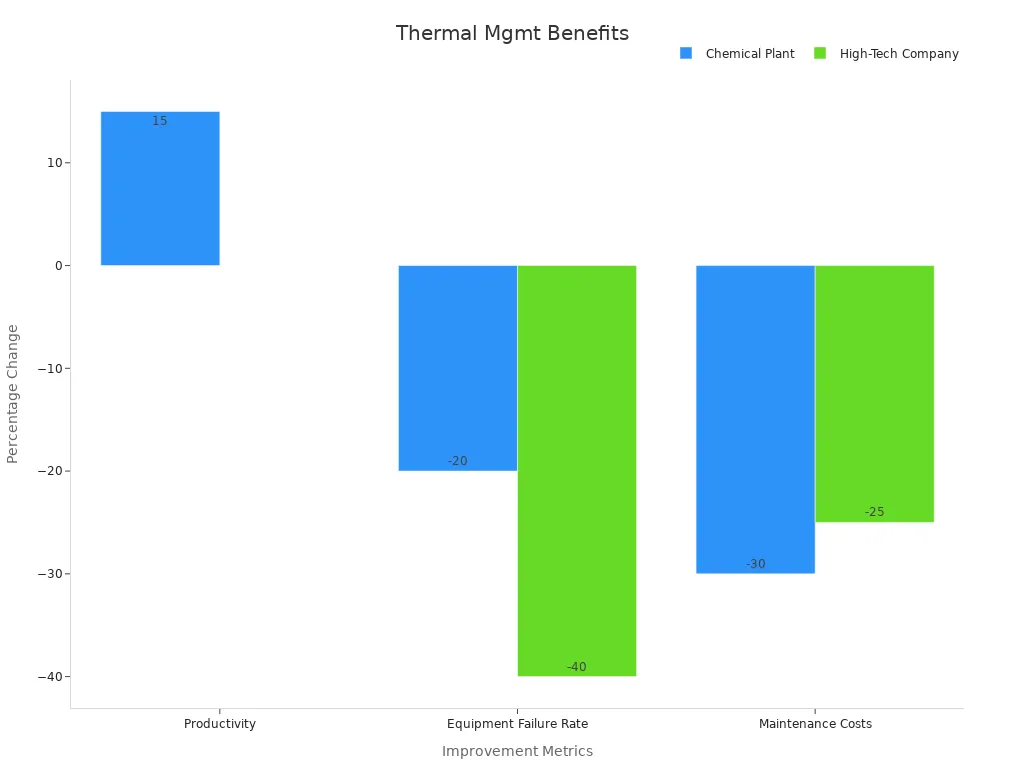

Studies show good heat control helps many industries. For example:

|

Case Study |

Improvement Type |

Results |

|---|---|---|

|

Chemical Plant |

Productivity |

Went up by 15% |

|

Equipment Failures |

Dropped by 20% |

|

|

Maintenance Costs |

Cut by 30% |

|

|

High-Tech Company |

Equipment Failures |

Dropped by 40% |

|

Maintenance Costs |

Cut by 25% |

These examples show how heat control improves reliability and lowers costs. The HVC50’s design keeps your system cool and running smoothly over time.

Fast current stopping for safety

Safety is very important in high-power systems. The HVC50 stops high currents quickly. It can handle up to 1500 V and 1000 A, stopping them in 30 milliseconds. This protects your system from damage caused by faults or overloads.

Its gas-filled ceramic arc chamber adds extra safety. It stops electrical arcs when cutting off current. This keeps your system safe, even in tough conditions. Mirror contacts also give accurate feedback, improving safety and reliability.

Using the HVC50 makes your charging system safer and more efficient. Its safety features protect your setup and help meet energy goals.

Enhancing Reliability and Scalability with HVC50

Strong design for lasting use

The HVC50 is made to last a long time. It is a dependable choice for high-power systems. Its tough build handles megawatt charging for years. The gas-filled ceramic arc chamber helps protect parts inside. This stops damage from high-voltage currents. It also lowers the need for replacements, saving time and money.

The sealed design keeps out dust, water, and heat. This makes it work well in factories or outside. Choosing the HVC50 means you get a system that works reliably for a long time.

Easy to expand with modular design

The HVC50’s modular design makes adding parts simple. You can upgrade without changing the whole system. For example, Husqvarna trimmers use modular setups to fit different brands. Wärtsilä engines show how modular designs meet various power needs.

With the HVC50, you can grow your charging system as energy needs rise. It works with new technologies, making upgrades easier. This saves money and makes your system more flexible.

Fits changing megawatt charging needs

The HVC50 adapts to growing energy demands. It supports industries like shipping and trucking. Modular charging systems for ships handle different power levels and sizes. Electric truck makers use modular designs for easy customization.

|

Source |

Evidence |

|---|---|

|

Ship Charging Systems |

Modular designs fit different power needs and ship sizes. |

|

Truck Charging Systems |

Modular setups allow site-specific scaling and upgrades. |

The HVC50 fits into these advanced systems easily. It handles up to 750 A at 1500 V, making it great for modern batteries. Using the HVC50 prepares your system for future energy challenges while staying reliable and efficient.

Real-World Uses of HVC50 in Megawatt Charging

Helping electric vehicle fleets

The HVC50 is important for charging electric vehicles like vans and buses. These vehicles need fast and reliable charging to stay on schedule. The HVC50 charges quickly and works with batteries up to 750 A at 1500 V.

It also keeps charging safe. Its gas-filled ceramic arc chamber stops overheating and electrical problems. This is helpful for long trips where charging takes longer. Adding the HVC50 to your fleet’s chargers can save money and reduce downtime.

Benefits for warehouses and logistics

Warehouses and delivery centers use electric forklifts and trucks to move goods. The HVC50 provides steady power for charging these vehicles. Its modular design lets you expand as your fleet grows. This is useful as more companies switch to electric vehicles.

The HVC50 also works with current systems, so upgrades are easy. For long trips, its quick current-stopping feature protects equipment from power surges. This keeps operations running smoothly and on time.

Supporting green transportation

The HVC50 helps make transportation more eco-friendly. As electric vehicles become popular, better chargers are needed. The HVC50 supports this by charging trucks and buses efficiently.

Its two-way energy flow sends extra power back to the grid. This helps save energy, especially with renewable systems. Using the HVC50 supports clean energy goals and meets the needs of electric vehicles.

Tip: Choosing advanced chargers like the HVC50 helps your business and supports global green goals.

The HVC50 solves big problems in megawatt charging systems. Its dual-coil design saves energy, the gas-filled ceramic chamber boosts reliability, and the modular design allows easy upgrades. These features make it essential for high-power systems.

Adding the HVC50 improves your charging setup. It boosts performance and speeds up the move to clean energy.

Using advanced tools like the HVC50 helps create a greener world while meeting rising energy needs.

Why is the HVC50 good for energy storage systems?

The HVC50 works well with high currents and voltages. It can charge and discharge energy efficiently. Its strong build and safety certifications make it reliable for long use.

How does the HVC50 make megawatt charging safer?

The HVC50 has a special gas-filled chamber to stop currents fast. Its sealed design keeps out dust and water, protecting parts inside. Mirror contacts give accurate feedback, improving safety in high-power systems.

Can the HVC50 handle future energy needs?

Yes, the HVC50’s modular design makes upgrades simple. It fits easily with current systems and grows with rising energy demands. This keeps it useful as technology changes.

How does the HVC50 help green energy goals?

The HVC50 saves energy by reducing power waste. Its dual-coil design uses less energy, supporting eco-friendly goals. It helps store and charge energy reliably, aiding clean energy systems.

Does the HVC50 meet global safety rules?

Yes, the HVC50 follows safety standards like CE, UKCA, and UL. These prove it is safe and works well worldwide. Its certifications ensure it fits with high-power systems everywhere.

See Also

Integrating AEAT-8800-Q24 to Improve Robotics Efficiency

Explore Essential Automotive Features of FREESCALE MCF5251CVM140

Enhancing Automotive Performance with NXP Microcontrollers MC9S12 Series

Three Key Benefits of XCF01SVOG20C in Industrial Automation

Three Effective Methods for Integrating MC9S12XET512VAG