In the rapidly evolving field of electronic technology, innovation and quality are the core drivers for a company’s establishment and growth. With the rapid development of the Internet of Things (IoT), Artificial Intelligence (AI), and 5G technology, the electronic components market is undergoing unprecedented transformation. As an engineer with years of experience in the electronics industry, I deeply understand that the performance and reliability of every tiny component directly impact the success or failure of the final product and the user experience. From the perspective of a professional engineer, this article will delve into the innovation pathways, key aspects of quality control in the field of electronic components, and combine practical application cases to outline future industry trends.

Innovation: The Perpetual Engine of Electronic Component Development

Innovation in electronic components is not achieved overnight; it is a complex process of continuous iteration and multi-party collaboration. From breakthroughs in materials science to advancements in manufacturing processes, and further to the innovation of design concepts, each step embodies the wisdom and hard work of engineers.

Continuous R&D and Technological Investment

Large electronics companies invest heavily in research and development annually, not only to launch new products but also to achieve breakthroughs at the fundamental technology level. For instance, in the semiconductor field, the continued evolution of Moore’s Law relies on the continuous exploration of new transistor structures (such as FinFET, GAAFET) and advanced packaging technologies (such as 3D stacking, Fan-Out packaging). These technological advancements enable the integration of more functionality into smaller chip volumes while reducing power consumption, providing powerful hardware support for areas like smartphones and high-performance computing.

Engineering Perspective: While designing high-speed communication modules, I encountered challenges with Signal Integrity. Traditional PCB routing and component selection could no longer meet the requirements for GHz-level transmission. By introducing low-dielectric-constant materials, optimizing impedance matching networks, and adopting transistors with higher cutoff frequencies (fT), we ultimately resolved the issue. This success was a direct reflection of innovation in materials science and semiconductor manufacturing processes.

Deep Industry-Academia-Research Integration

Universities and research institutions are cradles of theoretical research and cutting-edge technology exploration. Collaboration between companies and these institutions enables the rapid translation of innovative laboratory achievements into practical products. For example, in the field of MEMS (Micro-Electro-Mechanical Systems) sensors, many breakthrough technologies initially originated from university research in micro/nano fabrication. Through investment and cooperative development, companies apply these technologies to products like accelerometers, gyroscopes, and pressure sensors, widely used in consumer electronics, automotive, and medical devices.

Experience Sharing: I participated in a smart wearable project in collaboration with a university, involving the development of a novel biosensor. The university team possessed deep expertise in material and principle validation, while we provided support in engineering, reliability, and mass production. This complementary partnership significantly shortened the product development cycle from concept to market and provided us with invaluable cross-disciplinary learning opportunities on technical details.

Empowerment by Cutting-Edge Technologies

-

AI and Machine Learning: AI is reshaping the design, testing, and optimization of electronic components. For instance, AI algorithms can be used for automatic place-and-route, fault diagnosis, predictive maintenance, and even assisting in the design of more efficient Power Management ICs (PMICs). Through machine learning, chips can adaptively adjust performance to suit different workloads and environmental conditions.

-

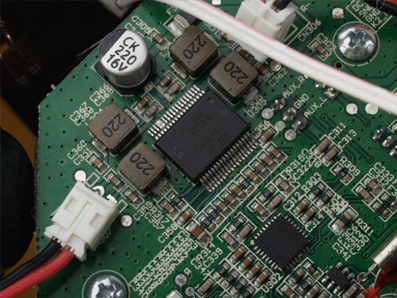

Internet of Things (IoT): The core of IoT lies in connectivity. Low-power, highly integrated MCUs (Microcontroller Units), wireless communication modules (Wi-Fi, Bluetooth, LoRa, NB-IoT), and various sensors form the foundation of IoT devices. Achieving seamless, secure communication between devices while ensuring ultra-low power consumption and long battery life is a key challenge for component manufacturers. The Power Management IC (PMIC) plays a critical role here, as its efficiency directly determines the practicality of IoT devices.

Technical Detail: Taking an IoT edge device as an example, its power consumption requirements are extremely stringent. I once selected a PMIC for a battery-powered smart agricultural sensor. The final choice was a PMIC featuring ultra-low Quiescent Current (IQ) and a high-efficiency DC-DC converter. This PMIC could automatically switch to Pulse Mode (P-mode) under light loads, further reducing power consumption, enabling the sensor to operate for years on just a button cell battery. This fully demonstrates the decisive role of components in system-level energy savings.

Implementation of Rigorous Testing Protocols

Automated Testing Systems

Automated testing systems play a crucial role in electronics quality control. These systems perform tests quickly and accurately. Automated processes reduce human error. Companies achieve consistent results with these technologies. Automated testing enhances efficiency in manufacturing.

Real-time Monitoring and Feedback

Real-time monitoring provides immediate insights into production. Feedback loops allow for quick adjustments. Manufacturers detect issues early with this technology. Real-time data ensures high-quality output. Consistent monitoring maintains product standards.

Compliance with Industry Standards

ISO Certifications

ISO certifications guarantee adherence to international standards. Companies demonstrate commitment to quality through certification. ISO standards cover various aspects of production. Certification builds trust with consumers. Businesses gain a competitive edge with ISO compliance.

Environmental and Safety Regulations

Environmental regulations ensure sustainable practices. Companies follow guidelines to minimize environmental impact. Safety regulations protect workers and consumers. Compliance reduces risks in manufacturing. Adhering to regulations enhances brand reputation.

Case Study: NSMM – Scanning Microscopy Technique

NSMM offers a method to detect defects by measuring electromagnetic properties. This technique requires traceable calibration methods. NSMM supports ultrafast electronics manufacturing with confidence.

Case Study: Emulait Compliance Testing Process Optimization

Emulait optimized its compliance testing process. The company achieved significant time and cost savings. Streamlining avoided compliance hurdles effectively.

Trends Driving Excellence in Electronics

Development of Smaller Components

Miniaturization transforms the electronics industry. Engineers design smaller components to enhance device portability. Compact designs allow devices to fit into everyday life. Manufacturers focus on creating powerful yet small electronics. This trend enables wider societal penetration. The mobility industry benefits greatly from miniaturization.

Energy-efficient Designs

Energy efficiency drives innovation in electronics. Designers prioritize low power consumption. Energy-efficient designs reduce environmental impact. Consumers prefer devices with longer battery life. Companies develop solutions to meet these demands. Energy-saving technologies enhance product appeal.

Consumer Demand for Smart Devices

Rise of Wearable Technology

Wearable technology gains popularity among consumers. Smartwatches lead the charge in this category. These devices offer advanced features for users. Health monitoring and connectivity attract buyers. Revenue from smartwatches is projected to reach $7.1 billion. Wearables become essential in daily routines.

Smart Home Innovations

Smart home products revolutionize living spaces. Consumers seek convenience and security in homes. Smart devices address these concerns effectively. Hardware revenue for smart home products is expected to grow by 3%. Innovations in this sector enhance safety and comfort. The demand for smart home solutions continues to rise.

Challenges and Solutions in Maintaining Excellence

Addressing Supply Chain Issues

Sourcing High-quality Materials

Companies prioritize sourcing high-quality materials. Reliable suppliers ensure consistent product excellence. Manufacturers evaluate suppliers based on quality standards. Regular audits verify compliance with industry requirements. Businesses maintain strong relationships with trusted partners.

Managing Global Supply Networks

Efficient management of global supply networks is crucial. Companies coordinate logistics to ensure timely delivery. Advanced software tracks shipments and inventory levels. Real-time data helps optimize supply chain operations. Businesses adapt to changes in demand and market conditions.

Historical Insight: The introduction of standardized shipping containers in the 1950s revolutionized logistics. This innovation laid the foundation for modern supply chains.

Industry Trends: Miniaturization, High Performance, and Intelligence

The future development of electronic components will continue to evolve towards being “smaller, faster, more power-efficient, and smarter.”

Miniaturization and Increased Integration

From wearable devices to medical implants, the demand for smaller component sizes is ever-increasing. SiP (System in Package) and SoC (System on Chip) technologies integrate more functions into a single package, reducing PCB area, lowering power consumption, and enhancing system reliability. For example, the latest smartwatch heart rate sensor modules can integrate photodiodes, LED drivers, analog front-ends, and an MCU within a package just a few millimeters square.

The Pursuit of Ultimate Energy Efficiency

As battery technology faces increasing bottlenecks, improving the energy efficiency of components has become paramount. The application of wide-bandgap semiconductor materials (like SiC and GaN) in power devices significantly enhances power conversion efficiency and reduces losses, showing immense potential especially in electric vehicles, data centers, and fast-charging applications.

Engineering Insight: While designing a high-power-density power supply, I initially tried using traditional silicon-based MOSFETs. However, due to switching losses and thermal challenges, I couldn’t meet the design targets. After switching to GaN FETs, their lower on-resistance and faster switching speed allowed us to double the switching frequency while significantly reducing the size of inductors and capacitors, ultimately achieving a smaller and more efficient power module.

Proliferation of Smart Devices and Growing Demand

The rapid development of smart homes, smart healthcare, autonomous driving, and other fields places higher demands on sensors, processors, memory, and communication modules. These components must not only offer high performance but also support complex algorithm processing, while possessing high reliability and security.

Collaboration for Win-Win Outcomes: The Value of Keep Booming Technology Limited

Distributors like Keep Booming Technology Limited play a bridging role, connecting upstream brands with downstream manufacturers. Their partnerships with industry giants such as TI, ADI, NXP, ST, SAMSUNG, TDK, MURATA, among others, ensure supply chain stability and component quality.

My Perspective: As an engineer, I deeply understand the importance of choosing a reliable component supplier. A good distributor not only provides genuine components at competitive prices but also offers crucial support in technical assistance, inventory management, and emergency supply. Their insights into market trends can also provide valuable reference for our design and component selection. For instance, when a new project required a TI DSP, through Keep Booming, we could quickly obtain samples, technical documentation, and even access to TI’s direct technical support, which was critical for project scheduling and risk control.

Booming technology drives excellence in electronics by fostering innovation and quality control. The electronic components industry is a field full of challenges and opportunities. Innovation is the eternal theme, and quality is the foundation of survival. As engineers, we bear the mission of transforming these tiny components into products that change the world. Through continuous learning, deep collaboration, and the relentless pursuit of technical excellence, we can continue to break new ground in the wave of electronic technology, creating a smarter, more efficient, and brighter future.