The MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F operates as a synchronous current-mode PWM step-down voltage regulator. This device delivers efficient DC-DC conversion, making it important in modern power supply design. Studies show that synchronous current-mode PWM step-down operation achieves high efficiency, up to 97%, while improving power factor and reducing heat. Today’s power supply trends highlight the need for stable output, low ripple voltage, and advanced control techniques, all strengths of the XRP7664IDTR-F.

Key Takeaways

-

The XRP7664IDTR-F is a high-efficiency PWM controller that uses synchronous rectification to reduce energy loss and improve power conversion up to 97%.

-

It supports a wide input voltage range from 4.5V to 18V and delivers up to 2A output current, making it flexible for many power supply designs.

-

The controller operates at a fixed high switching frequency of 340 kHz, allowing smaller components and faster response to load changes.

-

Its compact 8-pin SOIC package and robust reliability tests make it ideal for use in both consumer electronics and harsh industrial environments.

-

Engineers choose this controller for its energy savings, stable output, and suitability in applications like portable devices, industrial machines, and solar power systems.

Overview

Device Type

The MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F belongs to the family of synchronous current-mode PWM step-down voltage regulators. This device uses advanced control techniques to manage power conversion efficiently. Engineers often select this type of controller for its ability to handle high-frequency switching and precise voltage regulation. The 8-pin SOIC package makes it compact and easy to integrate into various circuit boards.

Main Function

This controller regulates the output voltage by driving synchronous rectifiers, specifically MOSFETs, in a buck converter configuration. It uses current mode PWM control, which means it monitors the inductor current and adjusts the switching cycle by cycle. This method offers several advantages:

-

Faster response to changes in load.

-

Simplified compensation for stable operation.

-

Improved efficiency, especially in low-voltage applications.

Synchronous converters replace the traditional diode with a MOSFET. This change reduces forward voltage losses and increases efficiency, sometimes reaching up to 97%. The controller manages both the input switch and the synchronous MOSFET, ensuring they operate with precise timing to avoid short circuits. This careful management allows the device to deliver high performance and reliability in demanding power supply designs.

|

Aspect |

Description |

|---|---|

|

Main Function |

Drives synchronous rectifiers (MOSFETs) in buck converters using current mode PWM control to regulate output voltage cycle-by-cycle. |

|

Efficiency Role |

Replaces diode with synchronous MOSFET to reduce forward voltage drop, improving efficiency up to 97%. |

|

Application |

Used in portable computer and communication power supplies, enabling high-frequency operation and low noise interference. |

Typical Uses

Designers use the MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F in many applications. Common uses include:

-

Power supplies for embedded systems and industrial equipment.

-

Voltage regulation in consumer electronics.

-

Portable computer and communication devices.

-

Systems that require high efficiency and low heat generation.

Note: The controller’s ability to operate at high frequencies and deliver stable output makes it ideal for modern electronic devices that demand reliable and efficient power management.

MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F Features

Input and Output Voltage

The MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F supports a wide range of input and output voltages. This flexibility allows engineers to use the device in many different power supply designs. The input and output voltage capabilities include:

-

Input voltage range: 4.5V to 18V, with some designs operating as low as 2V.

-

Output voltage: Adjustable up to 16V.

-

Previous designs supported up to 6V output, but newer requirements often need up to 12V or more.

This broad voltage range makes the controller suitable for both legacy and modern systems. Devices that require higher output voltages, such as industrial controllers or advanced consumer electronics, benefit from this adaptability.

Output Current

The controller delivers a steady output current of up to 2A. This current rating supports a variety of loads, from small embedded devices to larger industrial modules. The single-channel design ensures that the device can focus its full capacity on one output, providing stable and reliable power. Many engineers choose this controller for applications where consistent current delivery is critical.

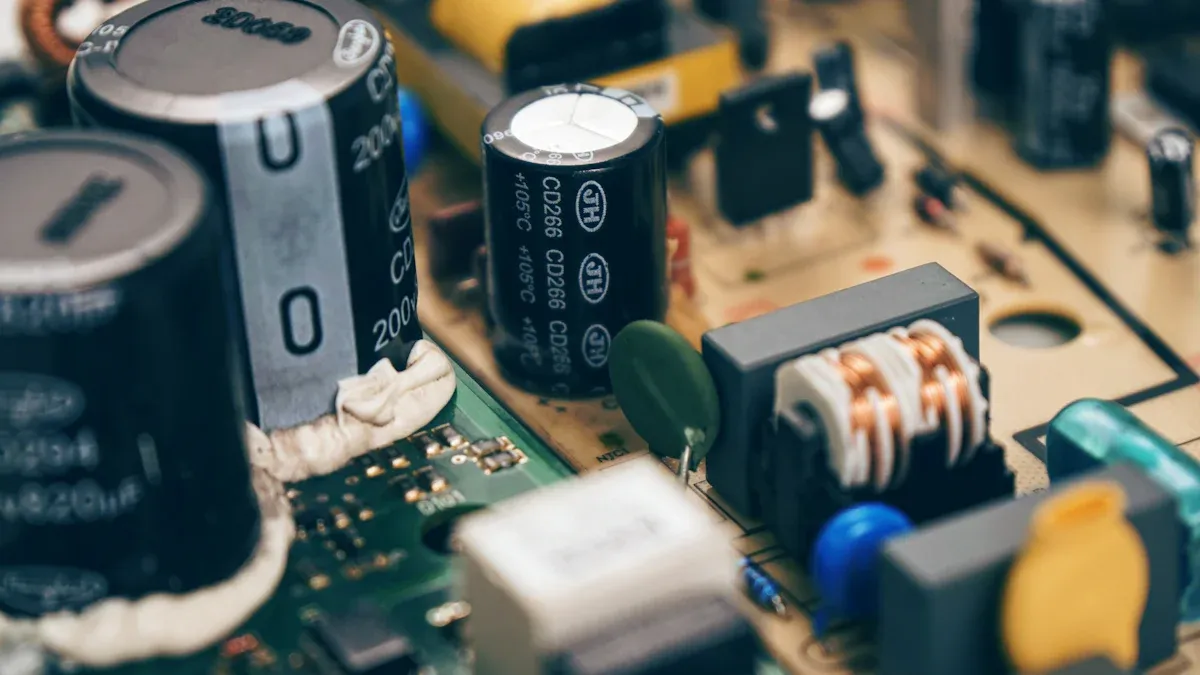

Switching Frequency

The MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F operates at a fixed switching frequency of 340 kHz. This high frequency enables the use of smaller inductors and capacitors, which helps reduce the overall size of the power supply. High-frequency operation also improves transient response, allowing the device to react quickly to changes in load. This feature is especially important in systems that require fast and stable voltage regulation.

Efficiency and Rectification

Synchronous rectification sets this controller apart from traditional buck converters. By replacing the standard diode with a low-resistance MOSFET, the device reduces conduction losses and boosts efficiency. Several studies have compared synchronous and asynchronous rectification methods. The results show that synchronous rectification can significantly improve efficiency, especially under heavy load conditions.

|

Study / Paper Title |

Key Findings on Efficiency Improvement |

Application Context |

|---|---|---|

|

Efficiency and Analysis of a Synchronous Buck Converter |

Demonstrates reduction of diode conduction losses, leading to enhanced converter efficiency; validated by simulation and hardware |

UPS battery charging |

|

Efficiency loss breakdown for synchronous rectification scheme for automotive applications |

Shows significant efficiency improvement compared to asynchronous rectification using MOSFETs with low on-resistance |

Automotive systems |

|

Design And Efficiency Comparison Of Synchronous Buck Converter With P, PI, PID Controllers |

Indicates better performance under heavy load by replacing diode with MOSFET switch; PID control improves efficiency under light load |

Control techniques and ZVS implementation |

|

Digital Multimode Buck Converter Control With Loss-Minimizing Synchronous Rectifier Adaptation |

Presents a multimode control strategy optimizing synchronous rectifier timing to minimize losses and improve efficiency over wide load range |

Digital control and load-dependent optimization |

These findings confirm that the MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F can help designers achieve high efficiency in demanding applications.

Package and Integration

The device comes in a compact 8-pin SOIC package. This small footprint makes it easy to integrate into crowded circuit boards. The controller supports an industrial temperature range, which means it can operate reliably in harsh environments. Reliability testing, such as High-Temperature Reverse Bias (HTRB) and High-Temperature Operating Life (HTOL), confirms the device’s robustness. The table below summarizes key reliability tests:

|

Test Type |

Purpose and Key Objectives |

Test Conditions and Parameters |

|---|---|---|

|

High-Temperature Reverse Bias (HTRB) |

Evaluates long-term stability under high drain-source bias; accelerates failure mechanisms at blocking junctions |

Static DC bias near max rated reverse breakdown voltage; temperature 125°C-175°C; >1000 hours; leakage current monitored |

|

High-Temperature Operating Life (HTOL) |

Validates expected performance over time without driving device to failure; longer duration than burn-in |

Temperature up to ~225°C; DC and RF testing to verify intrinsic reliability and application-specific performance |

|

Intermittent Operating Life (IOL) |

Tests package assembly integrity and bond wire reliability under thermo-mechanical stress |

Cycling drain bias on/off (e.g., 30s on/off, up to 5000 cycles); elevated baseplate temperature ~80-85°C |

|

Soft-Switching Test |

Accelerated life test for switching power devices; monitors changes in ON resistance (RDS-ON) under controlled switching |

Pulsed high voltage (OFF state) and high current (ON state) with no overlap; elevated temperature; microsecond scale tracking |

These tests ensure that the MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F meets industrial standards for reliability and integration. The robust design and proven reliability make it a strong choice for engineers working in challenging environments.

Benefits and Applications

Efficiency Advantages

Engineers value the MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F for its strong energy efficiency. PWM controllers often reach efficiencies between 75% and 80% in real-world systems. This makes them a cost-effective choice for applications where the input voltage closely matches the output, such as solar charging or battery-powered devices. In advanced systems like electric vehicle charging, PWM controllers can achieve up to 95% efficiency and a power factor of 0.99, showing excellent power quality and minimal energy loss.

|

Metric |

Value |

Application Context |

|---|---|---|

|

Efficiency |

95% |

EV charging (three-level PWM) |

|

Power Factor |

0.99 |

EV charging |

|

Transmission Efficiency |

83.5%-84.1% |

EV charging |

Many industries use PWM controllers to save energy and reduce costs. For example, precision motor control in factories lowers both energy use and equipment wear. Solar energy systems use PWM adjustments to increase energy yield. LED lighting systems benefit from PWM-driven dimming, which saves power. These advantages help engineers design reliable and efficient products.

Application Areas

The MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F finds use in a wide range of fields. Industrial machinery, food processing equipment, and CNC machines rely on PWM controllers for stable power and precise control. Communication equipment and embedded systems also benefit from their efficiency and reliability. In the solar energy sector, controllers optimize battery charging and energy storage, especially in off-grid or rural areas where stable power is critical.

Note: Case studies show that PWM controllers perform well in AC/DC power supplies, LED lighting, battery management, and smart home devices. They also support applications in automotive, medical, and telecom sectors, where fast response and stable operation are essential.

-

Electrical machinery

-

Food processing machinery

-

CNC machines

-

Communication equipment

-

Consumer electronics

-

Solar power systems

-

Smart home and building automation

Industrial Suitability

Manufacturers test PWM controllers under harsh conditions to ensure reliability. Thermal chamber testing simulates temperature cycling, thermal shock, and humidity. These tests reveal design flaws and help improve product durability. Devices also undergo rapid temperature changes to check for structural damage and changes in electrical properties. Temperature and humidity tests confirm performance in environments with high moisture or fluctuating conditions.

-

Thermal chamber testing improves reliability and helps meet industry standards.

-

Thermal shock testing uncovers weaknesses in electronic components.

-

Temperature and humidity testing ensures performance in tough environments.

-

HALT and HASS tests push devices beyond normal limits to verify long-term reliability.

-

Vibration testing checks that devices can withstand mechanical stress in industrial and military settings.

These rigorous tests show that the MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F can operate reliably in demanding industrial environments.

Why Choose XRP7664IDTR-F

Unique Value

The MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F stands out because it combines high efficiency with a wide input voltage range. Many engineers look for a controller that can handle different power sources. This device supports input voltages from 4.5V to 18V, which makes it flexible for many projects. The controller also delivers up to 2A of output current, which suits both small and medium-sized systems.

Synchronous rectification gives this controller a clear advantage. By using MOSFETs instead of diodes, the device reduces energy loss. This feature helps keep systems cool and extends the life of electronic parts. The fixed 340 kHz switching frequency allows designers to use smaller components, which saves space on circuit boards. The 8-pin SOIC package makes installation easy, even in tight spaces.

Tip: Engineers can use this controller in both consumer electronics and industrial machines. Its robust design and reliable performance make it a smart choice for demanding environments.

Market Comparison

When comparing the XRP7664IDTR-F to other PWM controllers, several features set it apart. Many controllers in the same class offer lower input voltage ranges or support less output current. Some devices do not include synchronous rectification, which means they waste more energy as heat.

The table below shows how the XRP7664IDTR-F compares to typical alternatives:

|

Feature |

XRP7664IDTR-F |

Standard PWM Controller |

|---|---|---|

|

Input Voltage Range |

4.5V – 18V |

4V – 15V |

|

Output Current |

Up to 2A |

1A – 1.5A |

|

Synchronous Rectification |

Yes |

No |

|

Switching Frequency |

340 kHz |

100 – 300 kHz |

|

Package |

8-pin SOIC |

8-pin SOIC or larger |

Engineers who need high efficiency and flexibility often choose the MaxLinear PWM Controller 18 V 340 kHz 8-Pin XRP7664IDTR-F. Its features help reduce energy costs and improve system reliability. This controller meets the needs of modern designs better than many standard options.

Engineers recognize the XRP7664IDTR-F as a reliable and efficient PWM controller for modern power supply designs. This device offers flexible output options, built-in protection features, and user-friendly controls. Many experts highlight its ability to improve productivity and reduce errors. Automation and data collection features help ensure consistent results. Regular calibration and robust warranty support add long-term value. These qualities make the XRP7664IDTR-F a smart choice for demanding projects in various industries.

What is the maximum input voltage for the XRP7664IDTR-F?

The XRP7664IDTR-F accepts input voltages up to 18V. This wide range allows engineers to use it in many different power supply designs.

Can the XRP7664IDTR-F operate in harsh environments?

Yes. The device supports an industrial temperature range. It passes reliability tests like HTRB and HTOL, making it suitable for demanding industrial settings.

How does synchronous rectification improve efficiency?

Synchronous rectification uses MOSFETs instead of diodes. This change reduces energy loss during switching. The controller achieves higher efficiency, especially under heavy loads.

What package type does the XRP7664IDTR-F use?

The controller comes in a compact 8-pin SOIC package. This small size helps engineers save space on circuit boards.

See Also

Enhancing Process Control Using The AD74413RBCPZ Device

Exploring The LPQ252-CEF For Optimized Power Efficiency

A Deep Dive Into MC9S12DJ256MFUE For Automotive Use

Improving Automotive Performance With NXP MC9S12XEP100 Series

How ARTESYN NPT42-M Drives Industrial Automation Power