The MLX90365LDC-ACD-000-RE stands as a pivotal component in automotive systems. Its ability to measure magnetic fields in three dimensions ensures precise position detection, crucial for applications like throttle and steering angle sensors. This sensor’s reliability and high precision make it indispensable in environments demanding accuracy and durability. With its compact design and robust performance, the MLX90365LDC-ACD-000-RE enhances vehicle functionality, meeting stringent automotive standards. For more detailed specifications, visit this datasheet.

Understanding MLX90365LDC-ACD-000-RE

Technical Specifications

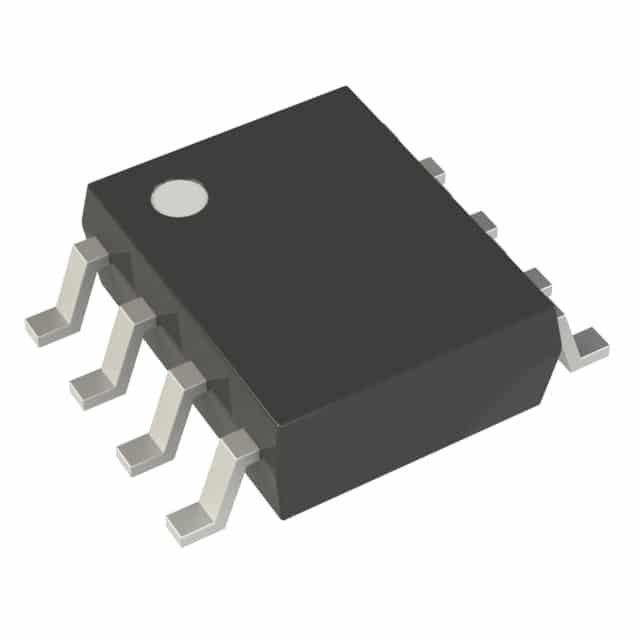

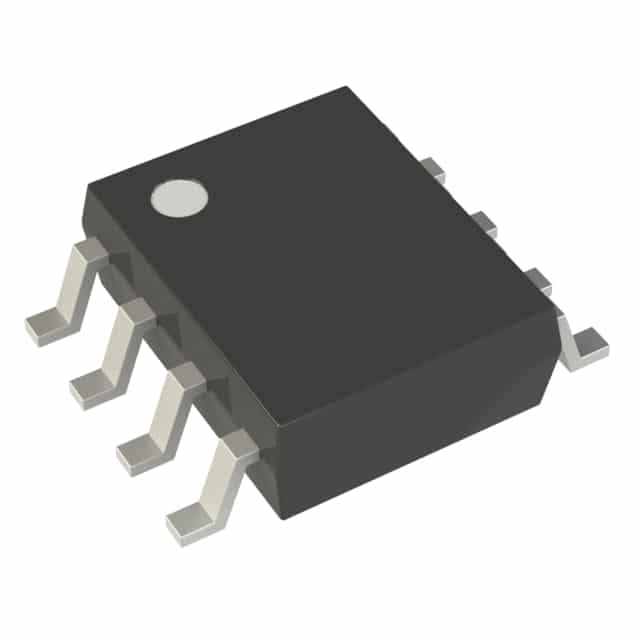

The MLX90365LDC-ACD-000-RE is a sophisticated Hall Effect sensor designed for precision in automotive applications. It operates with a supply voltage of 5.5V, providing an analog output essential for accurate position measurement. The sensor comes in a compact SOIC-8 package, making it suitable for integration into tight spaces within vehicle systems. Its ability to measure magnetic fields in three dimensions (X, Y, and Z axes) allows for versatile application in various automotive components. The sensor’s design ensures it meets the stringent requirements of automotive environments, including temperature, vibration, and electromagnetic interference.

Functionalities of the Sensor

The MLX90365LDC-ACD-000-RE offers a range of functionalities that enhance its utility in automotive systems:

-

Position Detection: The sensor excels in detecting linear and rotary positions, making it ideal for throttle position sensors and steering angle sensors.

-

Output Versatility: It provides both analog and PWM signals, allowing for flexible integration into different systems.

-

Reliability: Designed to withstand harsh automotive conditions, the sensor maintains performance in environments with high temperatures and vibrations.

-

Precision: Its high accuracy ensures reliable data for systems requiring precise control, such as electric power steering and gear shifters.

These features make the MLX90365LDC-ACD-000-RE a valuable component in enhancing vehicle performance and safety.

Benefits in Automotive Systems

Precision and Accuracy

The MLX90365LDC-ACD-000-RE sensor excels in delivering high precision and accuracy. It measures magnetic fields in three dimensions, ensuring precise position detection. This capability proves essential in automotive systems where exact measurements are crucial. For instance, throttle position sensors rely on this precision to control the throttle body accurately. Steering angle sensors also benefit from this accuracy, providing reliable data for electric power steering systems. The sensor’s ability to deliver consistent and precise measurements enhances the overall performance of these automotive components.

Reliability and Durability

Automotive environments demand components that can withstand harsh conditions. The MLX90365LDC-ACD-000-RE sensor meets these demands with its robust design. It operates effectively in high temperatures and vibrations, maintaining performance without degradation. This reliability ensures that the sensor continues to function optimally over time, reducing the need for frequent replacements. Its durability makes it a preferred choice for applications like pedal position sensors and gear shifters, where consistent performance is vital.

Efficiency and Performance Enhancement

The integration of the MLX90365LDC-ACD-000-RE sensor into automotive systems leads to significant efficiency and performance enhancements. By providing accurate and reliable data, the sensor enables systems to operate more efficiently. For example, in motor position feedback applications, the sensor’s data allows for precise control of brushless DC motors, improving their efficiency. This efficiency translates to better fuel economy and reduced emissions in vehicles. Additionally, the sensor’s compact design facilitates easy integration into various systems, further enhancing vehicle performance.

Integration Process

Integrating the MLX90365LDC-ACD-000-RE sensor into automotive systems requires careful attention to detail. This section provides a comprehensive guide to ensure a successful installation and operation.

Step-by-Step Guide

Required Tools and Equipment

To begin the integration process, gather the necessary tools and equipment. These include:

-

A soldering iron for secure connections.

-

Wire cutters and strippers for preparing wires.

-

A multimeter to verify electrical connections.

-

Mounting brackets or adhesive for sensor placement.

-

Protective gloves and eyewear for safety.

Installation Steps

Follow these steps to install the MLX90365LDC-ACD-000-RE sensor:

-

Identify the Installation Location: Choose a location that allows the sensor to measure the magnetic field accurately. Ensure it is free from obstructions and interference.

-

Prepare the Wiring: Use wire cutters to trim the wires to the appropriate length. Strip the ends to expose the conductive material.

-

Connect the Sensor: Solder the wires to the sensor’s terminals. Ensure each connection is secure to prevent signal loss.

-

Mount the Sensor: Use mounting brackets or adhesive to secure the sensor in place. Ensure it is stable and aligned correctly with the magnetic field source.

-

Verify Connections: Use a multimeter to check the electrical connections. Ensure the sensor receives the correct voltage and outputs the expected signal.

Safety Precautions

Safety is paramount during the installation process. Follow these precautions:

-

Wear protective gloves and eyewear to prevent injuries.

-

Ensure the vehicle’s power supply is disconnected before starting the installation.

-

Avoid contact with sharp tools and hot surfaces.

-

Double-check all connections to prevent electrical hazards.

Testing and Calibration

After installation, testing and calibration ensure the sensor operates correctly. Follow these steps:

-

Initial Testing: Power the system and observe the sensor’s output. Use a multimeter to verify the signal matches the expected values.

-

Calibration: Adjust the sensor’s position if necessary to achieve accurate readings. Use calibration tools to fine-tune the sensor’s output.

-

Final Verification: Conduct a series of tests to confirm the sensor’s performance under various conditions. Ensure it maintains accuracy and reliability.

By following this guide, the MLX90365LDC-ACD-000-RE sensor can be effectively integrated into automotive systems, enhancing their functionality and performance.

Common Challenges and Solutions

Potential Integration Issues

Integrating the MLX90365LDC-ACD-000-RE sensor into automotive systems can present several challenges. Installers may encounter issues such as incorrect sensor alignment, which can lead to inaccurate readings. Misalignment often occurs when the sensor is not positioned correctly relative to the magnetic field source. Another common issue involves electrical interference from nearby components, which can disrupt the sensor’s output signal. Additionally, improper wiring connections can result in signal loss or sensor malfunction. Identifying these potential problems early can prevent costly errors and ensure a smooth integration process.

Troubleshooting Tips

When facing integration challenges, several troubleshooting tips can help resolve issues effectively:

-

Check Alignment: Ensure the sensor aligns properly with the magnetic field source. Adjust its position if necessary to achieve accurate readings.

-

Inspect Wiring: Examine all wiring connections for security and correctness. Re-solder any loose connections and verify that wires are not damaged.

-

Reduce Interference: Identify sources of electrical interference and reposition the sensor or interfering components to minimize disruption.

-

Test Output: Use a multimeter to measure the sensor’s output signal. Compare the readings with expected values to identify discrepancies.

-

Review Installation Steps: Revisit the installation guide to confirm that each step was followed correctly. Small oversights can lead to significant issues.

These troubleshooting tips can help maintain the sensor’s performance and reliability in automotive systems.

Best Practices for Avoiding Problems

Adhering to best practices during the integration process can prevent many common issues:

-

Plan Thoroughly: Before starting, plan the installation process carefully. Identify potential challenges and prepare solutions in advance.

-

Use Quality Tools: Employ high-quality tools and equipment to ensure secure connections and accurate measurements.

-

Follow Manufacturer Guidelines: Adhere to the manufacturer’s instructions and specifications for installation and operation.

-

Conduct Regular Maintenance: Perform routine checks and maintenance on the sensor and its connections to ensure long-term reliability.

-

Document the Process: Keep detailed records of the installation and any adjustments made. This documentation can be invaluable for future troubleshooting.

By following these best practices, installers can enhance the success of integrating the MLX90365LDC-ACD-000-RE sensor into automotive systems, ensuring optimal performance and longevity.

The MLX90365LDC-ACD-000-RE sensor offers numerous benefits and straightforward integration steps, making it a valuable asset in automotive systems. Its precision, reliability, and efficiency enhance vehicle performance and safety. Mastering this sensor is crucial for those looking to improve automotive systems. By understanding its functionalities and integration process, users can unlock its full potential. Further exploration and application of the MLX90365LDC-ACD-000-RE in various car systems can lead to innovative solutions and advancements in automotive technology.

See Also

Understanding MC9S12DJ256MFUE Specs for Car Technologies

Unveiling Key Automotive Attributes of FREESCALE MCF5251CVM140

Three Essential Features of R5F64219JFB for Audio Gear

Guide to Using ATA5824C in Remote Control Devices

In-Depth Overview of DSPs for Automotive Audio Systems