Modern vehicles feature increasingly complex advanced driver-assistance systems (ADAS) and in-vehicle infotainment (IVI) systems. These systems generate and process vast amounts of data, driving the Automotive Software Market to an estimated USD 18.19 billion in 2025. Memory ICs form the foundation for performance, safety, and user experience in these automotive systems. They handle critical data for real-time processing. Selecting the right memory is crucial. It must meet stringent automotive requirements like functional safety, extreme environmental conditions, and high reliability. By 2025, over 50% of automotive applications will use Universal Flash Storage (UFS) devices to manage this growing data. This guide helps engineers navigate memory selection decisions for next-generation automotive designs. Considering a component like MT40A1G16TB-062E:F for Advanced Driver Assistance Systems ADAS and In-Vehicle Infotainment Systems requires assessing its memory performance.

Key Takeaways

-

Modern cars need special memory chips for safety features and entertainment. These chips help systems work fast and reliably.

-

Choosing the right memory is important. It must handle lots of data, work in hot or cold weather, and keep drivers safe.

-

Different car systems need different memory types. Safety systems need very fast memory, while entertainment systems need lots of storage.

-

Future cars will need even more memory. This memory will be faster, safer, and more integrated to handle new technologies.

ADAS and IVI System Demands in 2025

The year 2025 marks a significant period for automotive technology. Vehicles will feature smarter safety systems and more intelligent infotainment. These advancements place immense demands on memory solutions. The sheer volume of data generated and processed by these systems requires robust and efficient memory.

ADAS Memory Requirements

Advanced Driver-Assistance Systems (ADAS) rely on real-time processing of vast sensor data. Cameras, radar, and lidar generate continuous streams of information. The system must quickly analyze this data to detect hazards, assist with parking, or enable autonomous driving features. This requires high-speed, low-latency memory to ensure immediate responses. Artificial intelligence and machine learning algorithms also demand substantial memory for their operations. These algorithms process complex patterns and make critical decisions. The projected increase in ADAS memory capacity is staggering. It will grow from over 385 million GB by the end of 2022 to 2.1 billion GB by 2026. This represents an approximate 445% increase. This growth highlights the critical need for advanced memory solutions in these automotive systems.

IVI Memory Requirements

In-Vehicle Infotainment (IVI) systems focus on enhancing the user experience. They require memory for fast boot-up times, smooth graphical interfaces, and seamless multitasking. Drivers and passengers expect quick access to navigation, media playback, and communication features. IVI systems also store large amounts of data, including high-definition maps, multimedia libraries, and application software. Reliable memory is essential for over-the-air (OTA) updates, ensuring the system remains current and secure. The overall performance of the infotainment system directly depends on its memory capabilities.

Shared and Unique Memory Needs

Both ADAS and IVI systems share common memory requirements. They both need high reliability and robust operation in harsh automotive environments. Both systems also handle significant amounts of data. However, their priorities differ. ADAS systems demand extremely high bandwidth and low-latency memory for safety-critical functions. Any delay in data processing can have severe consequences. IVI systems, while needing good performance, prioritize user experience and large storage capacity. They require memory that can support rich multimedia and complex applications. Understanding these distinct and shared memory requirements is crucial for selecting the right components.

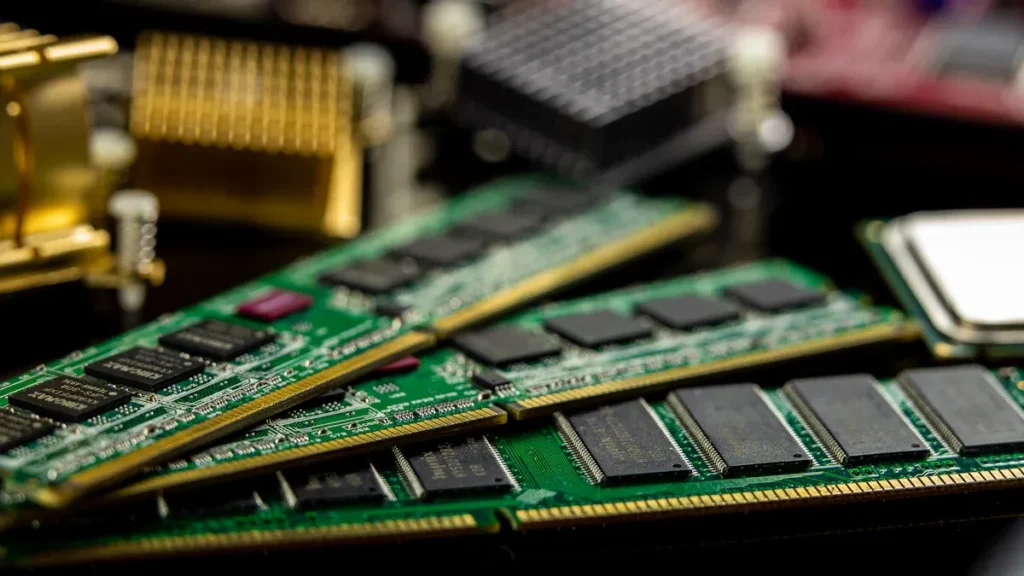

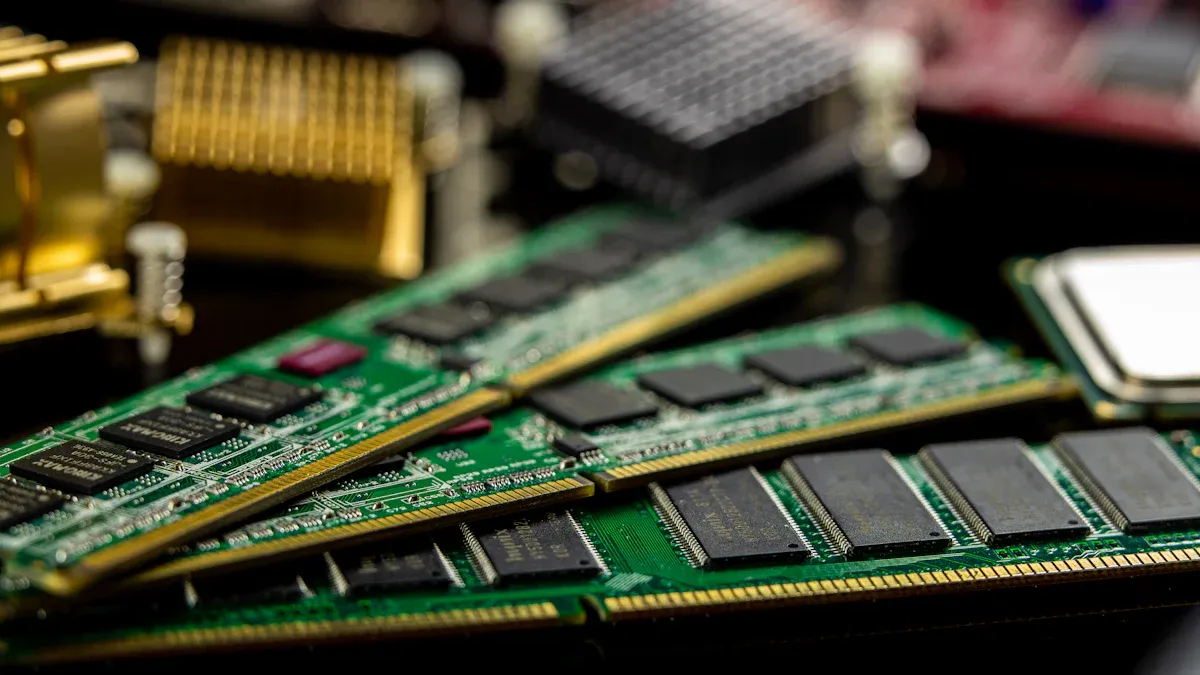

Essential Automotive Memory Technologies

Automotive systems rely on various memory technologies. Each type offers specific advantages for different applications. Engineers select these based on factors like speed, capacity, and cost.

DRAM Technologies

Dynamic Random Access Memory (DRAM) is crucial for active data processing. Low-Power Double Data Rate (LPDDR) memory, specifically LPDDR5 and LPDDR5X, offers high performance and power efficiency. These are ideal for demanding ADAS and IVI systems. Double Data Rate (DDR) memory, such as DDR4 and DDR5, provides a cost-effective solution for many IVI applications. Graphics Double Data Rate (GDDR6) memory delivers extreme bandwidth for niche ADAS applications. GDDR6 SDRAM offers per-pin data rates from 14 to 18 Gbit/s. Commercial versions reach up to 24 Gbit/s per pin. A common 384-bit bus at 16 Gbit/s per pin provides up to 768 GB/s of bandwidth. Higher rates like 18 Gbit/s exceed 864 GB/s on the same bus. Complex data processing in Level 3 and higher ADAS systems requires memory bandwidths exceeding 200 GB/s. Experts estimate advanced driver assistance systems will ultimately demand 512 GB/s to 1024 GB/s bandwidth for Level 3 and 4 autonomous driving.

Non-Volatile Memory (NVM)

Non-Volatile Memory (NVM) retains data even without power. Universal Flash Storage (UFS) provides high-performance storage. UFS has dedicated channels for reading and writing data. This allows simultaneous data flow. It uses command queuing to group and reorder commands, maximizing throughput. UFS cards support a high-speed serial interface with separate transmit and receive lanes. This allows simultaneous data transmission. UFS 3.1 devices offer twice the read performance and a 50% improvement in sustained write performance compared to UFS 2.1. UFS 3.0 can achieve speeds up to 2.9 GBps with two lanes. This is more than six times faster than eMMC transfers. UFS 3.1 enhances write performance through a ‘write booster’ feature. UFS uses a differential interface, making it resistant to transmission errors and noise. This improves EMI performance. UFS also achieves low power operation and includes enhanced security features like inline encryption.

Embedded MultiMediaCard (eMMC) offers cost-effective IVI storage. eMMC technology balances performance and cost. This makes it attractive for efficient storage in automotive electronics. This cost-effectiveness drives its demand. eMMC is a dominant choice for IVI storage in budget and mid-range vehicles.

NOR Flash memory is crucial for boot code. It stores essential code like boot code, application code, and operating systems. NOR Flash is resilient to harsh environments. It is ideal for storing firmware, navigation software, and diagnostic information. NOR Flash is crucial for safeguarding boot code and other critical data. Protection mechanisms apply to specific memory sections. If boot code is compromised, the entire system becomes inoperable.

NAND Flash provides mass storage. Over the next decade, in-vehicle storage capacities will range from 2TB to 11TB. NAND Flash is used in infotainment systems for multimedia and navigation data. It supports ADAS for sensor data streams. It also handles Vehicle-to-Everything (V2X) communication for cryptographic keys. NAND Flash stores large firmware files for Over-the-Air (OTA) software updates. It is also used for data logging and black box functions.

Emerging Memory Technologies

New memory technologies continue to develop. These aim to meet future automotive demands. They promise even higher speeds, greater densities, and improved power efficiency.

Key Memory Selection Criteria for 2025

Choosing the right memory for automotive systems in 2025 involves many critical factors. Engineers must consider more than just speed or capacity. Every automotive memory component requires AEC-Q100 qualification. This standard ensures quality and reliability. For ADAS, ISO 26262 functional safety compliance is also essential. These standards guide the entire memory selection process.

Performance Metrics

High performance is crucial for both ADAS and IVI systems. ADAS needs rapid processing of sensor data. This requires high bandwidth and low latency memory. The system must react instantly to changing road conditions. IVI systems demand quick boot-up times and smooth user interfaces. Fast data access ensures a responsive experience for navigation and multimedia. The overall performance of the vehicle’s electronic systems depends heavily on these metrics.

Reliability and Durability

Automotive memory must operate flawlessly in harsh environments. The AEC-Q100 standard sets strict stress tests for integrated circuits. This ensures their quality and reliability. Automotive components must withstand extreme temperatures. Grade 0 components, for example, operate from -40°C to +150°C. These are for critical areas like powertrain control. Grade 1 components handle -40°C to +125°C.

Automotive ICs differ from consumer products. They require designs focused on safety, security, and long life. They must endure vibrations, temperature extremes, and electrical noise. For non-volatile memory (NVM), specific requirements exist. These include fast boot times and instant response. NVM also needs support for frequent over-the-air (OTA) updates. High endurance and a long operational life are vital. Fast switching speed and innate security features also contribute to reliability.

Functional Safety (ISO 26262)

Functional safety is paramount for ADAS applications. The ISO 26262 standard provides guidelines for automotive electrical and electronic systems. It helps prevent unreasonable risks from system failures. Using fully ISO 26262, ASIL-D certified components offers the highest safety level. This approach often provides the lowest risk and fastest time-to-market.

ISO 26262-8, clause 13.4.1.1, classifies LPDDR DRAM as a Class III hardware element. Part 11 of ISO 26262 specifically adapts functional safety guidelines for semiconductors. It guides manufacturers in developing compliant IP, including DRAM. ADAS functions require automotive-grade IP that meets specific Automotive Safety Integrity Levels (ASILs). The entire hardware and software supply chain must follow this standard.

A strong safety culture must exist throughout development. This includes an independent Functional Safety (FuSa) manager. Documented Safety Plans and Safety Requirements are also essential. These define functional hardware and software safety mechanisms. Safety mechanisms like Error-Correcting Code (ECC), parity checking, and dual-core lockstep are necessary. These mechanisms must be assessed and validated to meet ASIL ISO 26262 safety requirements.

Power and Thermal Management

Efficient power and thermal management are crucial. Automotive systems often operate with limited power budgets. They also generate significant heat. Memory solutions must consume minimal power. This helps reduce the overall thermal load. Effective heat dissipation prevents performance degradation and extends component lifespan. Low-power memory technologies contribute to better fuel efficiency in electric vehicles.

Cost and Supply Chain

Cost remains a primary consideration in the automotive sector. It often ranks alongside performance. The choice of memory technology depends on whether the system is cost-driven or bandwidth-driven. DDR4 is the cheapest option. It offers cost-effectiveness, high-volume production, and simpler error correction. LPDDR4 is also a cost-effective choice, used in early ADAS designs. For heavily bandwidth-driven systems, HBM or GDDR are options. These imply higher costs than DDR4/LPDDR4. However, they offer efficiency in power and area for high performance. A stable supply chain is also vital. Manufacturers need a consistent supply of components to meet production demands.

Security Features

Memory safety is crucial for software development. It ensures reliable and secure operation. It prevents incorrect memory access. Vehicle software faces memory safety threats in key systems. Electronic Control Units (ECUs) in autonomous vehicles are vulnerable to v. This could lead to unauthorized control. In-Vehicle Infotainment Systems (IVI) are susceptible to heap-based overflow vulnerabilities. These allow arbitrary code execution. Advanced Driver Assistance Systems (ADAS) risk stack-based buffer overflows. These could alter sensor data and endanger safety. Connectivity systems are open to memory corruption attacks via 4G/5G, Bluetooth, and wireless CarPlay/Android Auto. These attacks enable remote access. Memory relocation techniques, like load-time function randomization, prevent exploitation. They randomize memory layout. This makes it difficult for attackers to predict function locations. It neutralizes exploit techniques like ROP and buffer overflows.

Strategic Memory Selection for Advanced Driver Assistance Systems ADAS and In-Vehicle Infotainment Systems

Strategic memory selection is vital for modern automotive systems. Engineers must carefully choose components, such as mt40a1g16tb-062e:f for advanced driver assistance systems adas and in-vehicle infotainment systems, to meet diverse application needs. This section provides specific examples of memory ICs suitable for various use cases. It illustrates the practical application of selection criteria.

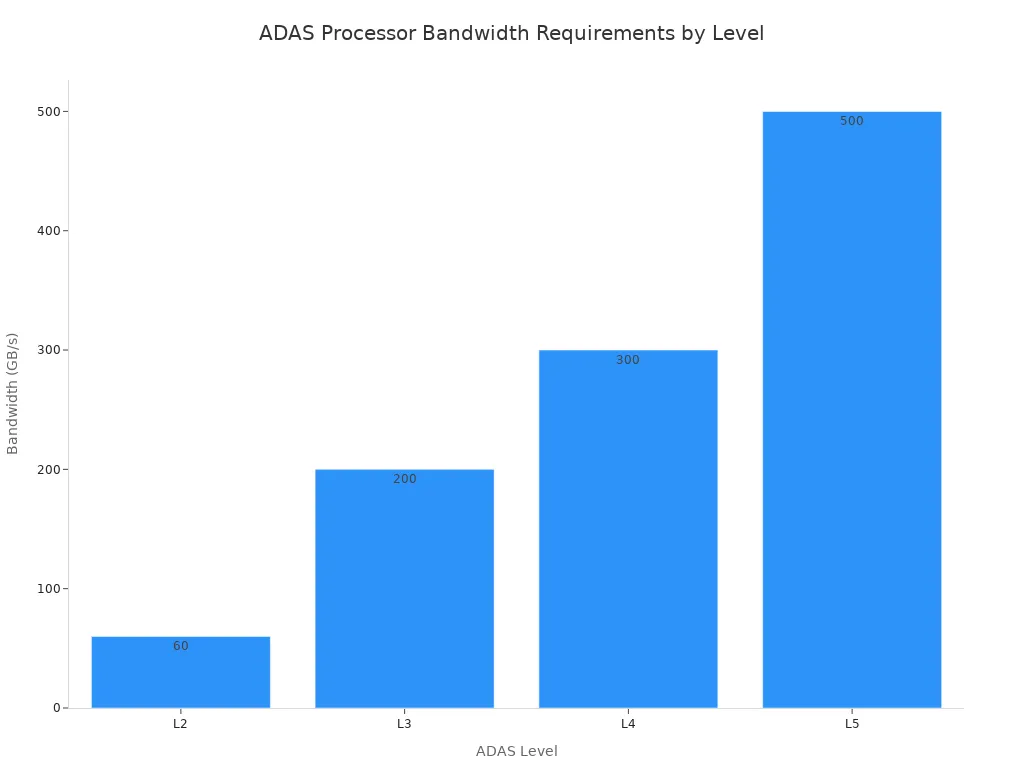

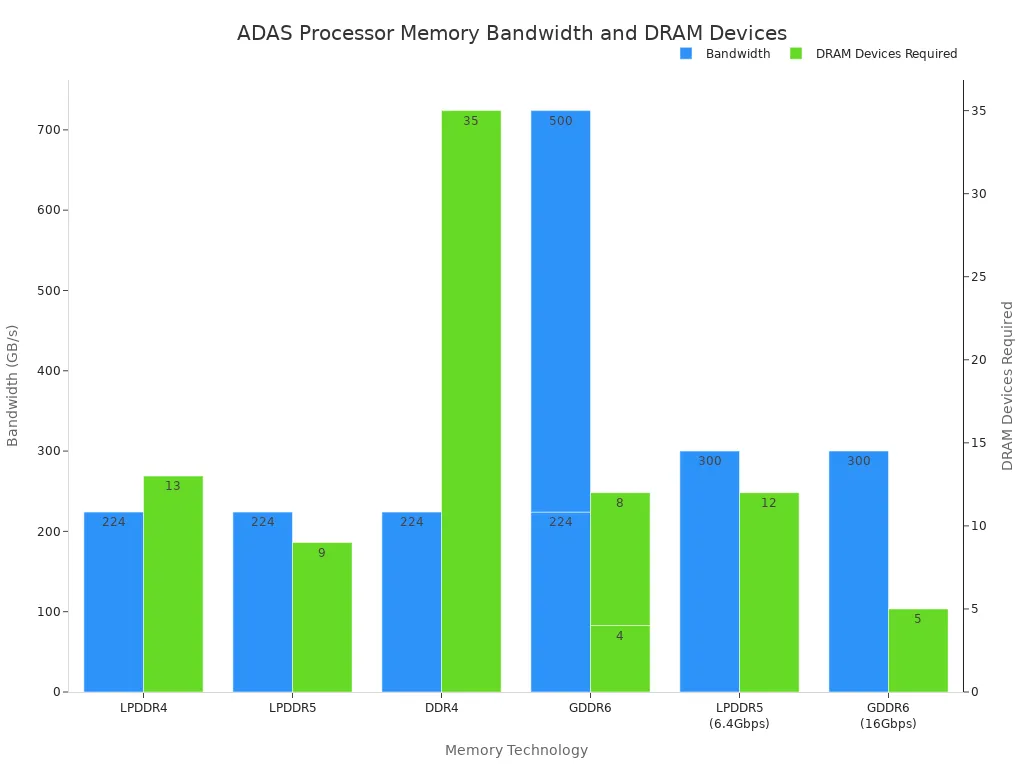

ADAS Processor Memory Needs

ADAS processors demand specific memory characteristics. They need instant access speeds. This enables real-time decision-making. Low latency reads are essential. This supports safety-critical logic execution. Random read speed can reach up to 104 MB/s. Latency can be as low as 50 ns. When memory cannot keep up with the data flow, problems arise. These include frame drops in video feeds. Sensor response also experiences delays. Overclocked processing can lead to system overheating.

Different ADAS levels have varying bandwidth requirements.

|

ADAS Level |

Bandwidth Requirement |

|---|---|

|

L2 |

~60 GB/s |

|

L3 |

>= 200 GB/s |

|

L4 |

300 GB/s |

|

L5 |

> 500 GB/s |

Selecting the right memory technology is crucial. It must meet these bandwidth demands efficiently.

|

Memory Technology |

Bandwidth |

DRAM Devices Required |

|---|---|---|

|

LPDDR4 |

224 GB/s |

13 |

|

LPDDR5 |

224 GB/s |

9 |

|

DDR4 |

224 GB/s |

35 (impractical) |

|

LPDDR5 (6.4Gbps) |

300 GB/s |

12 |

|

GDDR6 |

224 GB/s |

4 |

|

GDDR6 (16Gbps) |

> 300 GB/s |

5 |

|

GDDR6 |

> 500 GB/s |

8 |

Engineers evaluate specific components like mt40a1g16tb-062e:f for advanced driver assistance systems adas and in-vehicle infotainment systems. They assess its performance against the required bandwidth and latency. This practical application of selection criteria ensures optimal system functionality. The choice of memory, including options like mt40a1g16tb-062e:f for advanced driver assistance systems adas and in-vehicle infotainment systems, directly impacts the system’s ability to process real-time data. The overall performance and reliability of the ADAS system depend on this choice.

High-End Infotainment Memory

High-end infotainment systems require robust memory solutions. They support rich multimedia experiences. These include high-resolution displays and advanced navigation. Fast boot-up times are essential. Users expect quick access to features. Smooth multitasking between applications is also a must. Memory for these systems often includes high-speed LPDDR5 or LPDDR5X DRAM. It also uses high-capacity UFS flash storage. These technologies provide the necessary bandwidth and storage for large media files and complex software. For high-end infotainment, designers often consider robust solutions. A component like mt40a1g16tb-062e:f for advanced driver assistance systems adas and in-vehicle infotainment systems provides the necessary memory performance for demanding applications. This ensures a seamless user experience.

Entry-Level IVI and Telematics Memory

Entry-level IVI and telematics applications have different memory needs. Basic telematics systems often use Android-based processors. These systems require specific memory types. Flash and Dynamic Random-Access Memory (DRAM) are suitable. These memory modules are essential for storing information. This happens during unreliable or no network conditions. They also store vehicle data for future use. These memory types support advanced telematics functionalities. Speech recognition is one such function. Cost-effectiveness is a key factor here. eMMC flash storage is a popular choice. It balances performance with budget constraints. This makes it ideal for many entry-level automotive systems.

OTA Updates and Data Logging Memory

Over-the-Air (OTA) updates and data logging demand significant non-volatile memory. Vehicles constantly receive software updates. These updates can be large. They require reliable storage. Data logging captures vast amounts of operational data. This includes sensor readings and system diagnostics. This data is crucial for vehicle analysis and improvement. NAND flash memory is a common choice for mass storage. It handles these large data volumes. UFS flash offers higher performance for faster updates and data retrieval. For efficient OTA updates and robust data logging, a component like mt40a1g16tb-062e:f for advanced driver assistance systems adas and in-vehicle infotainment systems can support these critical functions. This ensures the long-term functionality and safety of automotive systems.

Future Trends in Automotive Memory

The automotive industry continues its rapid evolution. Connected driving features and live updating mechanisms will significantly influence future memory requirements. The global in-vehicle infotainment systems market will reach USD 24.77 billion in 2025. This growth drives demand for advanced memory solutions.

Increasing Bandwidth and Capacity

Future vehicles demand much higher memory bandwidth and capacity. High-density DRAM has supported advanced infotainment and ADAS systems since 2022. These systems require faster data processing and improved responsiveness. LPDDR5 and GDDR6 memory technologies have enhanced bandwidth and energy efficiency for real-time analytics and AI-assisted functions since 2023. Embedded NAND flash has gained traction for data logging, firmware storage, and over-the-air updates from 2024. Its compact form factor and high endurance make it suitable. MRAM and ReRAM technologies are emerging as promising alternatives for non-volatility, durability, and fast write speeds in safety-critical applications starting in 2025. Sophisticated ADAS and autonomous driving capabilities drive increasing demand for high-bandwidth memory (HBM and LPDDR5/5X). These advanced memory technologies handle immense data volumes from sensors. They also accelerate complex AI/ML algorithms for real-time perception and decision-making. Memory and storage requirements will increase by nearly 10 times over the next seven years. The average vehicle will use approximately 278GB of DRAM and NAND by 2026. Higher-end vehicles will reach up to 2TB. OEMs should select high-capacity memory and powerful chipsets to future-proof car hardware. This accommodates new capabilities from over-the-air updates.

Integration and Consolidation

Automotive architectures are shifting towards centralized compute. Vehicles move from many standalone ECUs to zonal designs. This reduces wiring and improves power efficiency. It also enables faster data exchange. This means higher demands for high-bandwidth DRAM, low-latency SRAM, and increased NAND flash density. These handle multiple real-time workloads. Software-Defined Vehicles (SDVs) allow functionality to be defined, updated, or activated via software. This simplifies production and enables shared electronic platforms. Memory and storage must accommodate current needs and future software evolution and data growth. BMW’s iX3 uses “four super brain” processing units. This highlights the pivot towards centralized processing where data is fundamental. This centralized computing architecture necessitates wider and higher bandwidth memory buses. It also requires secure virtualized spaces and flexible chip packaging.

Enhanced Security and Safety

Future automotive memory technologies will feature advanced security solutions. Branch Target Identification (BTI) enhances program execution integrity. Pointer Authentication (PAC) protects against memory corruption vulnerabilities. Memory Tagging Extension (MTE) helps detect and prevent memory safety errors. Manufacturers invest in these solutions. They leverage edge computing and computer vision to monitor for suspicious activity. They protect sensitive data. They ensure only authorized users can access vehicle systems. Robust cybersecurity safeguards personal information and road safety.

Sustainability and Longevity

Automotive memory design emphasizes sustainability and longevity. Quality requires stringent standards like low defective parts per million (DPPM) and IATF 16949 certification. Continuous testing throughout the device’s lifecycle is crucial. A vehicle’s 15+ year lifespan demands robust components. This addresses wear-out failures like aging and thermal effects. AEC-Q100 certification is a key standard. Functional safety, mandated by ISO 26262, requires error detection/correction and quick failure detection. Silicon Lifecycle Management (SLM) techniques, like on-chip path margin monitoring (PMM), extend SoC lifetime. They reduce operating voltage and stress. This helps optimize component lifespan.

Strategic memory selection is critical for ADAS and IVI systems in 2025. This complex decision balances performance, reliability, safety, and cost. Engineers must understand each automotive application’s specific data demands. They carefully evaluate available memory technologies against key criteria. Informed memory choices future-proof designs. They drive innovation and ensure the success and safety of next-generation vehicles. These choices effectively manage vast amounts of data, including sensor data and user data.

FAQ

What makes memory ICs critical for ADAS and IVI systems?

Memory ICs are foundational. They enable real-time processing of vast data. This ensures the performance and safety of ADAS. They also provide a smooth user experience for IVI systems.

What are the main differences in memory needs for ADAS and IVI?

ADAS needs high bandwidth and low latency for safety-critical functions. IVI systems prioritize large storage and smooth user interfaces. Both require high reliability in harsh automotive environments.

What is AEC-Q100 qualification?

AEC-Q100 is a standard for automotive integrated circuits. It ensures quality and durability. All automotive memory components must meet this qualification. It guarantees they withstand harsh conditions.

How does ISO 26262 apply to automotive memory?

ISO 26262 is a functional safety standard. It applies to ADAS systems. It helps prevent risks from system failures. Memory components for ADAS must comply with this standard.

See Also

MC9S12DJ256MFUE: Automotive Electronics’ Core, Explored And Implemented Hands-On

MC9S12XET512VAG Microcontroller: Integrating Automotive Systems With Strategic Practice

MC9S12XEQ512CAL: Deep-Dive Applications In Automotive And Industrial Control

Unlocking FREESCALE MCF5251CVM140: Essential Features For Automotive Innovation

SPC56 Microcontrollers: Mastering Automotive Powertrains Through In-Depth Application