Modern electronics, such as smartphones and laptops, depend on effective heat management to maintain optimal performance and reliability. With increased power density and compact designs, these devices generate significant heat, which can reduce semiconductor switching speeds by up to 15% and double component failure rates for every 10°C rise in temperature.

Recent advancements in two-phase cooling systems have achieved a coefficient of performance (COP) of up to 100,000, setting new standards in thermal management for electronics.

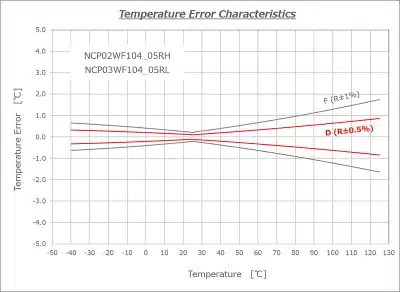

Murata NCP Series NTC Thermistors NCP02WF104D05RH offer a state-of-the-art solution for precise temperature detection. Designed with a compact footprint, these thermistors ensure high accuracy, making them ideal for managing heat in a wide range of applications, including consumer electronics, industrial systems, and even devices utilizing Murata capacitors and resistors.

Key Takeaways

-

Murata’s NCP Series thermistors detect temperature accurately within ±0.1°C. This is important for making electronics work well and reliably.

-

Their small size saves space on circuit boards, helping them fit better in modern gadgets.

-

These thermistors can be used in cars, home electronics, and factory machines. They help control heat effectively.

-

The heat control market is growing fast because devices need to be smaller and use less energy.

-

Murata’s smart designs stop devices from overheating. This helps high-power gadgets like electric cars and smart devices last longer and work better.

Challenges in Heat Management

Increased power density and heat generation in electronics

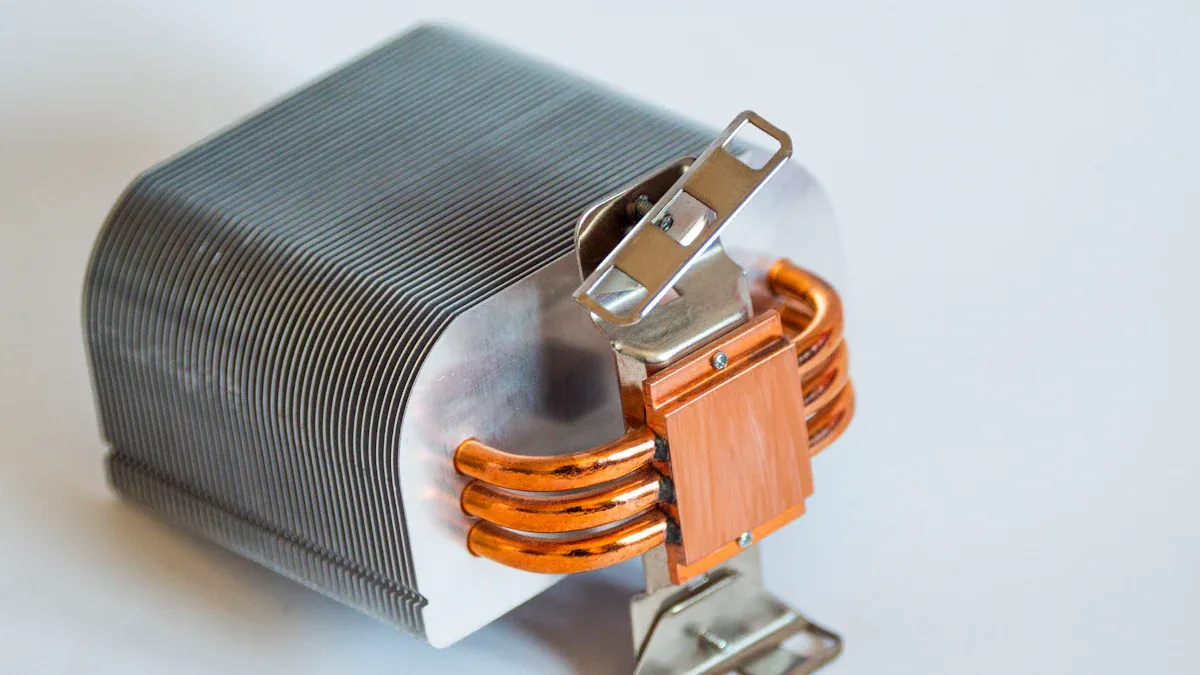

Modern electronics face significant thermal management challenges due to increased power density. Devices like smartphones and laptops now rely on advanced materials such as silicon carbide (SiC) and gallium nitride (GaN). These materials operate at higher voltages and frequencies, generating substantial heat. This trend is particularly evident in high-power applications, including electric vehicles, where robust thermal management ensures reliability and efficiency. Thermal simulations also highlight the importance of heat dissipation techniques. For instance, heat sinks with fins outperform flat plate designs by enhancing heat exchange. As power density rises, effective thermal management becomes critical to prevent pcb overheating and performance issues.

Miniaturization and its impact on thermal interface materials

The miniaturization of electronic devices has transformed the role of thermal interface materials. Smaller devices pack more heat-generating components into limited spaces, increasing the demand for efficient heat dissipation techniques. The thermal interface materials market reflects this trend, with projections showing growth from $3.9 billion in 2023 to $6.8 billion by 2028. This growth underscores the importance of these materials in maintaining device performance and longevity. Variability in thermal interface material performance, however, can lead to overheating, making their selection crucial in compact designs.

Diverse thermal management needs across industries

Industries face diverse thermal management challenges due to varying operational requirements. For example, high-power industrial systems demand robust thermal management to handle intense heat loads, while consumer electronics prioritize compact designs. A study by Malchaire et al. (2001) revealed that heat stress reduces physical work capacity, impacting productivity. Ioannou et al. (2017) found that total output declines as temperatures rise, emphasizing the need for effective thermal management across sectors. These findings highlight the importance of tailoring types of thermal management to specific applications, ensuring both efficiency and reliability.

Features and Benefits of Murata’s NCP Series Thermistors

High-precision temperature detection with ±0.1°C accuracy

Murata’s NCP Series thermistors excel in delivering high-precision temperature detection, achieving an impressive accuracy of ±0.1°C at 25°C. This level of precision is critical in applications where even minor temperature fluctuations can lead to significant consequences. For instance, laboratory tests have shown that 91.4% of results are influenced by temperature variations. Elevated temperatures can alter kidney function tests, such as creatinine and blood urea nitrogen levels, potentially leading to misdiagnoses. Similarly, lipid panels used in cardiovascular risk assessments may underestimate risks due to temperature-induced inaccuracies. These findings highlight the importance of precise thermal management in medical and industrial applications.

The NCP Series thermistors ensure optimal performance by maintaining consistent temperature readings, even in challenging environments. This capability makes them indispensable for industries requiring reliable thermal performance, such as healthcare, automotive, and consumer electronics.

Compact design for advanced cooling technologies

The compact design of the NCP Series thermistors sets them apart from traditional thermal management solutions. Available in 0402M and 0603M sizes, these thermistors occupy significantly less space on high-density circuit boards. The 0603M model reduces volume by approximately 80% and the mounting area by 70%, while the 0402M model achieves even greater reductions of 90% in volume and 80% in mounting area. This smaller footprint enables faster response times and seamless integration into advanced cooling technologies.

A comparison of cooling technologies further underscores the benefits of compact designs:

|

Feature |

Immersion Cooling |

Traditional Air Cooling |

|---|---|---|

|

Power Density |

Enhanced |

Limited |

|

Thermal Performance |

Superior |

Moderate |

|

Floor Space Efficiency |

Optimized |

Inefficient |

|

Equipment Life |

Extended |

Shorter |

|

Power Usage Effectiveness |

Greater |

Lower |

The table illustrates how compact components like the NCP Series thermistors contribute to optimized floor space and superior thermal performance. These advantages make them ideal for applications requiring advanced cooling technologies, such as data centers and electric vehicles.

Enhanced reliability and compatibility with existing designs

Reliability is a cornerstone of the NCP Series thermistors. Murata has designed these components to withstand rigorous operating conditions, ensuring long-term performance. Reliable products reduce the risk of costly product recalls, safety issues, and brand reputation damage. They also minimize customer dissatisfaction and legal liabilities, making them a preferred choice for manufacturers.

The NCP Series thermistors are compatible with previous models, such as the 1005M size, allowing for seamless integration into existing designs. This backward compatibility simplifies the design process and reduces the need for extensive rework. By maintaining high reliability and compatibility, the NCP Series thermistors support diverse applications, from consumer electronics to industrial systems, ensuring consistent thermal management across various sectors.

Applications of NCP Series Thermistors

Automotive: Electric vehicles and battery thermal management

The automotive industry increasingly relies on advanced thermal management solutions to ensure the safety and performance of electric vehicles (EVs). Murata’s NCP Series thermistors play a pivotal role in battery management systems (BMS), where precise temperature sensing is critical. These thermistors help prevent thermal runaway, a phenomenon that can compromise battery safety and efficiency.

Key features of Murata’s thermistors make them ideal for automotive applications:

-

Compact size (as small as 0.6 × 0.3 mm) allows integration into high-density designs.

-

High-speed response enhances temperature control in battery cells.

-

Compliance with AEC-Q200 standards ensures reliability in harsh automotive environments.

|

Feature |

Description |

|---|---|

|

Thermal Control |

High-precision temperature detection to prevent thermal runaway |

|

Temperature Precision |

Minimum variance of 0.18°C at 25°C |

|

Assembly Cost |

Reduced due to surface mounting on flexible substrates |

|

Response Time |

High-speed response due to increased contact area with cell surface |

Murata’s thermistors also support overcurrent protection in engine control units and motor start applications in climate control systems. As automotive electronics grow more complex, the demand for precise temperature sensing continues to rise. These thermistors ensure energy-efficient operation and enhance the safety of high-power devices like EV batteries.

Consumer electronics: Smartphones, wearables, and laptops

Consumer electronics demand compact, efficient heat removal solutions to maintain performance and longevity. Murata’s NCP Series thermistors excel in this domain, offering high-precision temperature sensing for devices like smartphones, wearables, and laptops.

The market for augmented reality (AR) and virtual reality (VR) devices is expanding rapidly. Murata’s technology, originally developed for mobile phones, now supports AR and VR applications. Components such as wireless communication modules, sensors, and capacitors from Murata contribute to more compact and power-efficient devices.

-

AR and VR devices benefit from Murata’s thermistors for precise thermal management.

-

Miniaturized designs ensure seamless integration into high-density circuit boards.

-

Efficient heat removal enhances device performance and user experience.

|

Evidence |

Description |

|---|---|

|

Market Value |

The Global Thermal Management Market was valued at USD 44.75 billion in 2020. |

|

Consumer Electronics Growth |

Increased disposable income in countries like China and India has significantly improved electronics consumption. |

|

Dominant Segment |

Consumer electronics dominate due to high thermal interface material usage. |

Murata’s thermistors address the challenges posed by miniaturization trends in chipsets and processors. By ensuring effective thermal management, these components extend device longevity and support energy-efficient operation in high-power devices.

Industrial systems: Robotics, IoT devices, and power supplies

Industrial systems, including robotics and IoT devices, require robust thermal management to handle intense heat loads. Murata’s NCP Series thermistors deliver high-precision temperature sensing, making them indispensable in these applications.

Murata’s thermistors are recognized for their rapid thermal response and stability. These qualities make them ideal for robotics, where precise temperature control ensures optimal performance. In IoT devices, efficient heat removal is critical to maintaining connectivity and functionality.

-

High-precision thermistors support temperature sensing in IoT devices.

-

Rapid thermal response enhances performance in robotics and power supplies.

-

Stability ensures long-term reliability in industrial systems.

Murata’s thermistors also play a key role in power supplies, where they help manage heat generated by high-power devices. By ensuring consistent thermal management, these components contribute to the reliability and efficiency of industrial systems.

Comparison with Traditional Heat Management Solutions

Advantages of NCP02WF104D05RH over conventional thermistors

Murata’s NCP02WF104D05RH thermistors outperform traditional thermistors in several key areas. Their compact size allows for seamless integration into high-density circuit boards, reducing the overall footprint by up to 80%. This feature is particularly beneficial for modern electronics, where space constraints are a significant challenge. Unlike conventional thermistors, which often struggle with precision, the NCP02WF104D05RH achieves an impressive accuracy of ±0.1°C at 25°C. This level of precision ensures consistent thermal management, preventing issues like lowered reliability or shortened lifespan in electronic components.

The advanced design of Murata’s thermistors also enhances their response time. Faster thermal detection enables more efficient heat dissipation, which is critical in applications such as electric vehicles and IoT devices. By addressing these challenges, the NCP02WF104D05RH sets a new standard for thermal management solutions.

Cost-effectiveness and improved performance in thermal management

Murata’s commitment to innovation extends beyond product design to include cost-effectiveness. The company has implemented energy-saving measures, such as renewable energy and storage battery facilities, in its manufacturing plants. These initiatives have significantly reduced power costs, with an estimated Value at Risk (VaR) of up to several tens of billions of yen. This approach not only lowers production costs but also aligns with Murata’s Vision2030 strategy, enhancing its competitiveness in the market.

The NCP Series thermistors deliver improved performance by maintaining stable operation under varying conditions. Their high reliability minimizes the risk of component failure, reducing maintenance costs and ensuring long-term efficiency. These factors make Murata’s thermistors a cost-effective choice for industries seeking advanced thermal management solutions.

Scalability for future electronic designs

The scalability of Murata’s NCP Series thermistors positions them as a vital component for future electronic designs. The growing demand for IoT sensors in wearables and home automation highlights the need for compact, high-precision components. Murata’s thermistors cater to these requirements, ensuring compatibility with emerging technologies.

|

Evidence Description |

Implication for Murata’s NCP Series Adoption |

|---|---|

|

Increased demand for IoT sensors in consumer applications like wearables and home automation. |

Suggests a growing market for Murata’s NCP Series, which can cater to these applications. |

|

Larger market size expected for wireless network technology during the forecast period. |

Indicates that Murata’s NCP Series can leverage advancements in wireless technology for better integration in future designs. |

|

Adoption of IPv6 enhances connectivity for IoT devices. |

Supports the need for Murata’s NCP Series to be compatible with future communication standards, ensuring longevity in designs. |

|

Exponential growth opportunities in IoT through cross-domain collaborations. |

Highlights the potential for Murata’s NCP Series to be integrated into diverse applications, enhancing its market scalability. |

The table above illustrates how Murata’s thermistors align with technological advancements, ensuring their relevance in a rapidly evolving market. Their adaptability makes them an ideal choice for industries aiming to future-proof their designs.

Effective heat management plays a pivotal role in ensuring the reliability and efficiency of modern electronics. Murata’s NCP Series thermistors address this need with cutting-edge features, including high-precision temperature detection, compact designs, and enhanced reliability. These thermistors cater to diverse applications, from electric vehicles to IoT devices, showcasing their versatility and scalability.

Key Takeaways:

-

Advanced Features: ±0.1°C accuracy, smaller footprint, and faster response times.

-

Applications: Automotive, consumer electronics, and industrial systems.

-

Market Impact: The thermal management market is projected to reach US$ 24.8 billion by 2032, driven by miniaturization and energy efficiency demands.

Murata’s innovative solutions redefine thermal management, ensuring optimal performance in high-power and compact devices. Explore the NCP Series thermistors to unlock advanced cooling technologies for the future. 🌟

What makes Murata’s NCP Series thermistors unique?

Murata’s NCP Series thermistors offer ±0.1°C temperature accuracy, compact sizes, and high reliability. These features ensure precise thermal management in compact and high-power devices. Their compatibility with previous models simplifies integration into existing designs, making them a versatile choice for various industries.

How do NCP Series thermistors improve thermal management?

These thermistors provide high-speed temperature detection and efficient heat dissipation. Their compact design reduces the mounting area by up to 80%, enabling faster response times. This ensures optimal performance in applications like electric vehicles, IoT devices, and consumer electronics.

Are Murata’s thermistors suitable for automotive applications?

Yes, the NCP Series thermistors meet AEC-Q200 standards, ensuring reliability in harsh automotive environments. They play a critical role in battery management systems by preventing thermal runaway and enhancing the safety and efficiency of electric vehicles.

Can NCP Series thermistors be used in medical devices?

Absolutely. Their high-precision temperature detection ensures accurate readings, which are essential in medical applications. These thermistors help maintain the reliability of devices like diagnostic equipment and wearable health monitors, ensuring consistent performance.

Where can I find more information about Murata’s NCP Series?

Visit Murata’s official website for detailed specifications, application notes, and product samples. The site provides comprehensive resources to help engineers and designers integrate NCP Series thermistors into their projects.

See Also

Enhancing Process Control With AD74413RBCPZ Unlocking Techniques

IRF820: A Versatile N-Channel MOSFET for Power Management

Reasons to Select Coilcraft XPL2010 for VRM/VRD Applications

Understanding MC9S12DJ256MFUE Specs for Automotive Uses

SPC56 Microcontrollers: Simplified Solutions for Engine Control