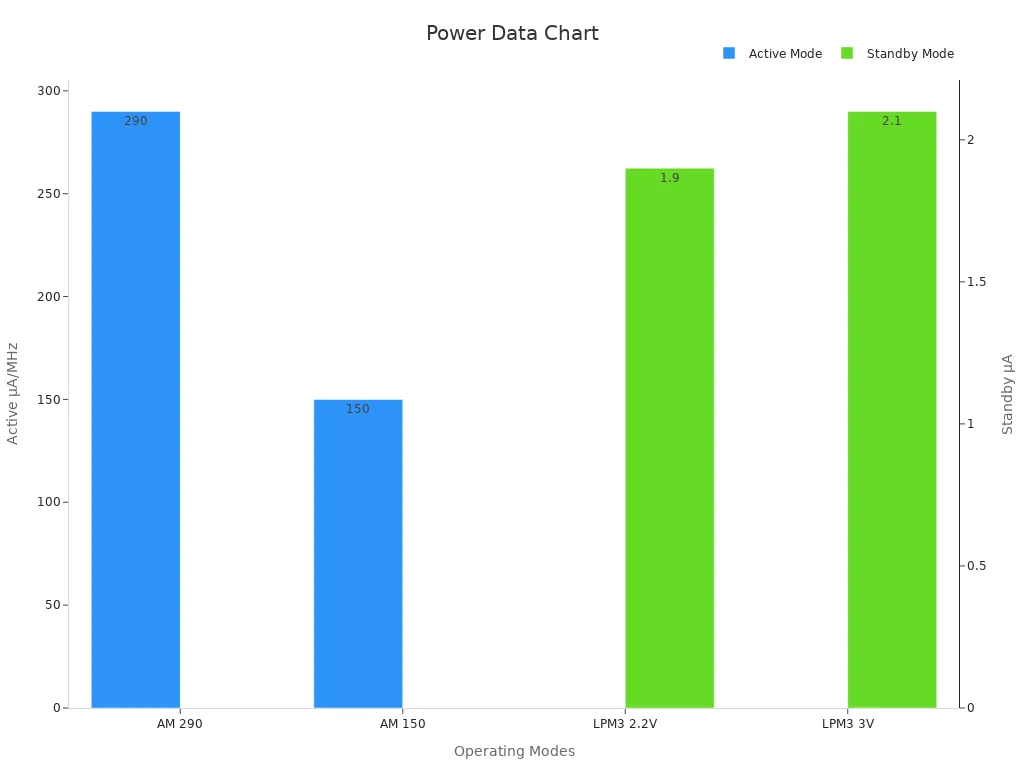

Industrial automation demands reliable and efficient solutions, and the MSP430F532x mixed-signal microcontroller from Texas Instruments delivers both. Its low power consumption and advanced features make it a standout option for mixed-signal applications. For instance, its active mode operates at just 290 µA/MHz during flash program execution, while standby mode consumes only 1.9 µA at 2.2 V. These power-saving modes ensure extended battery life, critical for industrial systems.

Selecting the right microcontroller requires evaluating specific needs like programmability, connectivity, and scalability. Texas Instruments offers robust development boards and an evaluation kit for testing, enabling engineers to optimize mixed-signal microcontroller chips for their designs. Understanding these factors ensures the best fit for industrial automation projects.

Key Takeaways

-

The MSP430F532x microcontroller uses very little power. This makes it great for devices that run on batteries in factories.

-

Its fast 16-bit design helps process data quickly. This is important for robots and smart devices that need instant responses.

-

It has built-in ways to connect, like SPI, UART, and I2C. These help it work easily with sensors and other gadgets.

-

The microcontroller’s flexible pins and extra features make it useful for many factory tasks.

-

Texas Instruments provides helpful tools and guides. These make it easier for engineers to design and improve their projects.

Key Requirements for Industrial Automation Applications

Industrial automation systems demand microcontrollers that meet specific requirements to ensure efficiency, reliability, and scalability. These requirements include power efficiency, real-time performance, and robust communication interfaces.

Power Efficiency and Low Power Modes

Power efficiency is critical for industrial applications, especially those relying on battery-powered devices. The MSP430F532x microcontroller excels in this area with its ultra-low power consumption. It supports multiple power modes, including active and sleep states, to optimize energy usage. For example, its sleep power mode significantly reduces energy consumption, extending battery life and minimizing operational costs.

|

Metric |

Description |

|---|---|

|

Power Consumption |

Total power used by a system, crucial for evaluating energy usage and identifying optimization areas. |

|

Power Efficiency |

Efficiency of converting input power into useful work, impacting resource utilization and heat dissipation. |

|

Energy Efficiency |

Overall energy consumption over time, important for battery-powered devices. |

|

Power Density |

Power dissipated per unit area, essential for avoiding overheating and enhancing reliability. |

|

Power Quality |

Stability of the power supply, critical to prevent performance issues. |

|

Sleep Power |

Power consumption in low-power sleep states, vital for energy conservation and battery life extension. |

These metrics highlight the importance of power efficiency in high performance applications, where energy savings directly impact system reliability and longevity.

Real-Time Performance and Processing Speed

Industrial automation requires microcontrollers capable of handling real-time data processing. The MSP430F532x microcontroller, with its high-performance 16-bit RISC architecture, ensures rapid response times. This capability is essential for applications like robotics, where real-time data directs precise movements.

-

Edge devices process real-time data from sensors to control industrial processes.

-

Robotics systems use real-time data to manage movements and actions.

-

IoT devices monitor and control connected systems using real-time data.

Performance benchmarks such as processor utilization, RAM usage, and I/O operations per second further illustrate the microcontroller’s ability to meet the demands of industrial automation.

Communication Interfaces and Connectivity

Reliable communication interfaces are vital for industrial controllers. The MSP430F532x microcontroller integrates multiple interfaces, including SPI, UART, I2C, and USB, to support diverse applications. These interfaces ensure seamless connectivity with sensors, actuators, and other devices.

|

Communication Interface |

Description |

Reliability |

Applications |

|---|---|---|---|

|

Industrial Ethernet |

Enhanced for harsh conditions, uses rugged components |

High reliability with real-time capabilities |

Manufacturing, motion control |

|

Fieldbus Systems |

Bus topology, multiple devices share a common channel |

Reliable and cost-effective |

Conveyors, medical equipment, wind turbines |

|

IO-Link |

Simplifies connections, supports various data types |

Reliable for simple devices |

Factory floor sensors and actuators |

|

Wireless Technologies |

Wi-Fi and Bluetooth for short-range, 5G for high data rates |

Less reliable in noisy environments |

Mobile machinery, autonomous vehicles |

These interfaces enable the MSP430F532x to integrate seamlessly into existing systems, making it a versatile choice for industrial automation.

Scalability and Memory Needs

Scalability plays a crucial role in industrial automation applications. Systems often need to adapt to growing data volumes and increasing complexity without compromising performance. The MSP430F532x microcontroller supports scalability through its flexible architecture and memory management capabilities. This makes it suitable for applications requiring dynamic resource allocation and parallel processing.

Memory requirements vary depending on the application. Industrial controllers often handle large datasets, real-time analytics, and sensor data processing. The MSP430F532x microcontroller addresses these needs with its efficient memory design. It includes flash memory for program storage and RAM for data handling, ensuring smooth operation even in demanding environments.

The microcontroller’s memory efficiency stems from advanced semiconductor technologies. These technologies optimize data movement, reducing energy consumption and enhancing performance. For example, in-memory compute is approximately 5,000 times faster than traditional spinning disks. This speed enables rapid data processing, which is essential for applications like robotics and precision manufacturing.

|

Statistic |

Description |

|---|---|

|

Speed |

In-memory compute is approximately 5,000 times faster than spinning disks. |

|

Scalability |

Supports dynamic resource allocation and parallel processing for growing data volumes. |

|

Efficiency |

Optimizes data movement for greater energy efficiency and low power consumption. |

The MSP430F532x microcontroller’s memory features also support scalability. Engineers can leverage its dynamic capabilities to meet evolving requirements in industrial automation. This adaptability ensures long-term reliability and cost-effectiveness, making it a preferred choice over 32-bit microcontrollers in many scenarios.

By addressing both scalability and memory needs, the MSP430F532x microcontroller provides a robust foundation for industrial automation applications. Its ability to handle increasing workloads while maintaining efficiency makes it an ideal solution for modern systems.

Features of the MSP430F532x Microcontroller for Industrial Automation

Ultra-Low Power Consumption

The MSP430F532x microcontroller is designed for applications requiring exceptional energy efficiency. Its ultra-low power consumption makes it ideal for battery-powered devices in industrial automation. The microcontroller supports multiple power modes, including active, standby, and off modes, to optimize energy usage based on operational requirements.

|

Mode |

Current Consumption (Typical) |

|---|---|

|

Active Mode (AM) |

290 µA/MHz at 8 MHz, 3 V |

|

150 µA/MHz at 8 MHz, 3 V |

|

|

Standby Mode (LPM3) |

1.9 µA at 2.2 V |

|

2.1 µA at 3 V |

|

|

Off Mode (LPM4) |

Full RAM Retention |

The ULPBench benchmark, developed by the Embedded Microprocessor Benchmark Consortium (EEMBC), confirms the microcontroller’s energy efficiency. This systematic analysis ensures credible and reliable performance data.

These advanced features allow the MSP430F532x to meet the stringent energy requirements of high performance applications, ensuring long-term reliability and cost savings.

High-Performance 16-bit RISC Architecture

The MSP430F532x microcontroller features a high-performance 16-bit RISC architecture, enabling it to deliver exceptional processing efficiency. This architecture supports rapid data processing and real-time responsiveness, which are critical for industrial automation. The processor operates at up to 25 MHz, ensuring it can handle complex tasks with ease.

The 16-bit RISC design reduces instruction execution time, allowing the processor to perform more operations per clock cycle. This efficiency is particularly beneficial for applications like robotics and precision manufacturing, where real-time data processing is essential. The architecture also minimizes power consumption during high-performance operations, aligning with the microcontroller’s energy-efficient design.

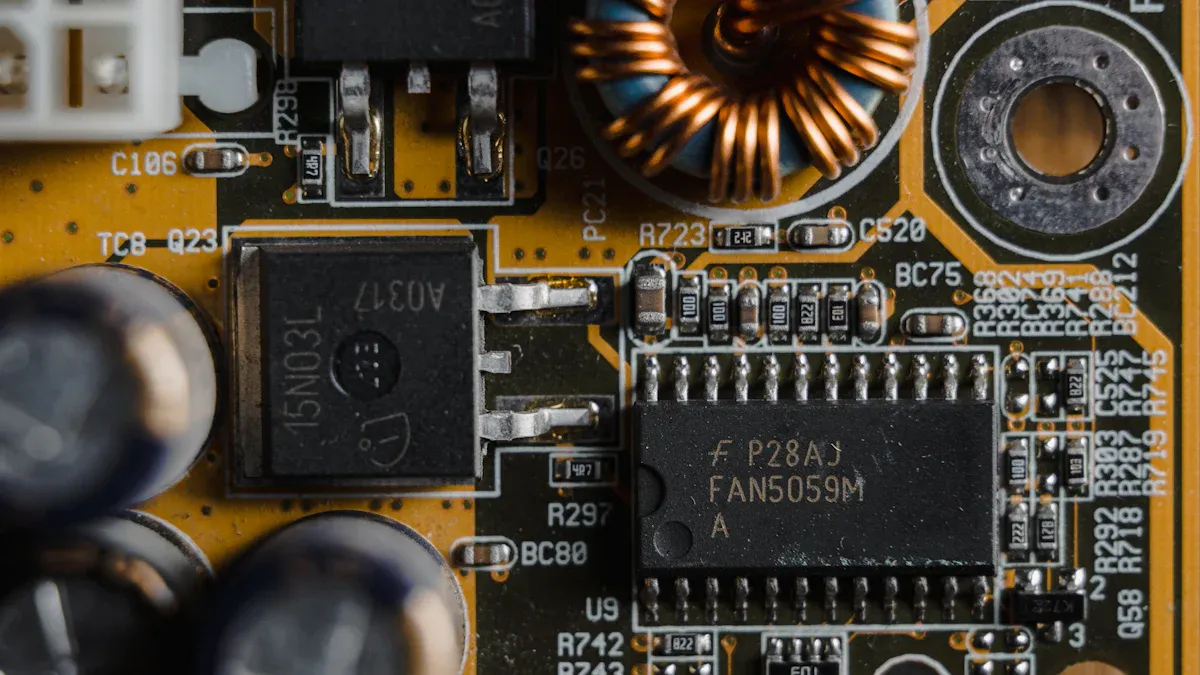

Integrated Communication Interfaces (SPI, UART, I2C, USB)

The MSP430F532x microcontroller integrates multiple communication interfaces, including SPI, UART, I2C, and USB. These interfaces enhance connectivity and enable seamless integration with sensors, actuators, and other devices in industrial systems. The USB 2.0 interface supports full-speed communication, making it suitable for applications requiring high data transfer rates.

|

Microcontroller Type |

Integrated Interfaces |

|---|---|

|

MSP430F532x |

SPI, UART, I2C, USB |

|

PIC |

UART, I2C, SPI, USB, CAN (higher-end) |

|

8051 |

N/A |

The microcontroller’s communication capabilities simplify system design and reduce the need for additional components. This versatility makes it a preferred choice for industrial automation, where reliable and efficient data exchange is crucial.

Flexible GPIO and Peripheral Options

The MSP430F532x microcontroller offers a wide range of GPIO (General-Purpose Input/Output) pins and peripheral options, making it highly adaptable for diverse industrial automation applications. With 47 GPIO pins, this microcontroller provides ample flexibility for connecting sensors, actuators, and other external components. These GPIO pins support multiple configurations, including digital input, digital output, and alternate functions, allowing engineers to tailor the microcontroller to specific system requirements.

|

GPIO Pins |

Count |

|---|---|

|

MSP430F532x |

47 |

The microcontroller also includes advanced peripheral features, such as timers, PWM (Pulse Width Modulation) modules, and ADC (Analog-to-Digital Converter) channels. These features enable precise control and monitoring of industrial processes. For example, the 12-bit ADC facilitates accurate signal conversion, which is essential for applications like sensor interfacing and data acquisition. Additionally, the microcontroller’s flexible GPIO design simplifies system integration, reducing the need for external components and minimizing design complexity.

The versatility of the MSP430F532x microcontroller ensures compatibility with a wide range of industrial automation systems. Its GPIO and peripheral options empower engineers to meet the unique requirements of their applications, enhancing both functionality and efficiency.

Robust Development Tools and Ecosystem

A strong development ecosystem is crucial for implementing industrial automation solutions effectively. The MSP430F532x microcontroller benefits from Texas Instruments’ comprehensive suite of development tools and resources. These tools streamline the design process, enabling engineers to prototype, test, and optimize their applications with ease.

Key elements of the development ecosystem include:

-

Dedicated teams of risk professionals, data scientists, and IT experts to address implementation challenges.

-

Robust data infrastructure to ensure accurate and consistent data inputs for automation systems.

-

Middleware solutions that facilitate seamless integration of automation technologies with existing systems.

-

Case studies, such as an automotive assembly plant integrating collaborative robots with legacy machinery, demonstrating the importance of middleware selection.

-

Cybersecurity tools and practices to protect interconnected systems from potential threats.

The availability of these resources simplifies the development process and reduces time-to-market for industrial automation applications. Engineers can leverage these tools to address complex requirements, ensuring reliable and efficient system performance. The MSP430F532x microcontroller’s robust development ecosystem underscores its suitability for modern industrial automation projects.

How to Choose a Microcontroller for Your Application

Evaluating Power Modes and Energy Efficiency

Energy efficiency plays a pivotal role in industrial automation applications. Engineers must evaluate power modes to ensure the microcontroller meets performance requirements while minimizing energy consumption. The MSP430F532x microcontroller excels in this area, offering ultra-low power modes that extend battery life and reduce operational costs.

Several metrics help assess energy efficiency across different power modes. Tools like ULPBench provide standardized benchmarks for ultra-low power microcontrollers. Devices such as EnergyMonitor measure energy consumption under specific conditions, enabling accurate evaluations. Software tests simulate active and low-power states to determine efficiency. Manufacturers like Texas Instruments participate in benchmarking processes to ensure credible results. Application variability also influences energy requirements, as IoT devices and battery-powered systems demand unique power profiles.

|

Metric |

Description |

|---|---|

|

ULPBench |

A benchmarking tool developed to evaluate energy efficiency of ultra-low power microcontrollers. |

|

EnergyMonitor |

A device that measures energy consumption under specific conditions, aiding in accurate assessments. |

|

Software Tests |

Tests designed to measure microcontroller efficiency under various active and low-power conditions. |

|

Manufacturer Involvement |

EEMBC includes all relevant manufacturers in the benchmarking process, ensuring credibility of results. |

|

Application Variability |

Different ULP requirements based on application type (e.g., IoT, battery-powered devices). |

Selecting the right microcontroller requires careful evaluation of these metrics. Engineers can leverage tools and benchmarks to identify the most energy-efficient option for their application.

Assessing Memory and Storage Requirements

Memory and storage capacity are critical factors in microcontroller selection. Industrial applications often demand high endurance and reliability, especially for mission-critical systems. The MSP430F532x microcontroller addresses these needs with embedded flash memory and efficient memory management.

Embedded Flash (eFlash) memory is widely used for built-in storage in microcontrollers. However, as on-chip memory capacity increases, eFlash faces scaling limitations. Emerging alternatives like spin-transfer torque MRAM (STT-MRAM) and resistive RAM (ReRAM) offer improved endurance and reliability. Single-level cell (SLC) flash storage remains ideal for high-performance applications due to its durability, though it is costly and limited in capacity. Recent advancements in 3D triple-level cell (TLC) NAND flash have made it viable for industrial use, with configurations that enhance endurance to levels comparable to SLC.

ATP’s development of 3D TLC-based SSDs configured as pseudo SLC (pSLC) demonstrates innovation in memory technology. These solutions achieve endurance levels near SLC while maintaining cost-effectiveness. Engineers must consider these advancements when assessing memory requirements for their application.

Reviewing I/O Capabilities and Peripheral Needs

The number of I/O pins and peripheral options significantly impacts microcontroller selection. Industrial systems often require multiple interfaces to connect sensors, actuators, and other devices. The MSP430F532x microcontroller offers 47 GPIO pins, providing flexibility for diverse applications.

|

Feature |

Description |

|---|---|

|

I/O Interfaces |

The number and type of I/O interfaces required for the application. |

|

Processing Speed |

The speed at which the microcontroller can process data, crucial for real-time applications. |

|

Memory Size |

Sufficient memory for program code and data processing needs. |

|

Power Consumption |

Efficiency in power usage, important for long-term operation in industrial settings. |

|

Communication Interfaces |

Availability of interfaces like SPI, I2C, or UART for device communication. |

Engineers should evaluate the number of I/O pins needed for their application. Processing speed and memory size must align with performance requirements. Power consumption should remain efficient for long-term operation. Communication interfaces like SPI, UART, and I2C enhance connectivity, simplifying system integration.

Microcontrollers are often preferred over PLCs for their compact design and cost-effectiveness. However, PLCs may be better suited for projects requiring high reliability and ease of maintenance. Engineers must weigh these factors carefully to select the microcontroller that best meets their application needs.

Ensuring Compatibility with Existing Systems

Industrial automation systems often rely on a mix of legacy and modern technologies. Ensuring compatibility between a new microcontroller and existing systems is essential for seamless integration. The MSP430F532x microcontroller offers features that simplify this process, making it a reliable choice for industrial environments.

Compatibility analysis involves evaluating the architecture, key features, and integration potential of the microcontroller. The table below highlights how different architectures compare in terms of compatibility with existing systems:

|

Microcontroller Architecture |

Key Features |

Compatibility Insights |

|---|---|---|

|

8051 Architecture |

Legacy platform, power-efficient, cost-effective |

Suitable for backward compatibility in existing systems, ideal for battery-powered devices and IoT applications |

|

ARM Architecture |

High performance, energy-efficient, scalable |

Versatile for various applications, strong security features for sensitive sectors like automotive and healthcare |

|

Resource-Constrained Devices |

Efficient resource utilization |

Reduces operational costs and energy consumption, ideal for large-scale industrial deployments |

The MSP430F532x microcontroller aligns well with resource-constrained devices. Its low power consumption and efficient resource utilization make it suitable for large-scale industrial systems. Additionally, its integrated communication interfaces, such as SPI, UART, and I2C, ensure smooth interaction with legacy devices. These features reduce the need for extensive system redesigns, saving time and costs during implementation.

When selecting a microcontroller, engineers should also consider the operating environment. Factors like temperature ranges, electromagnetic interference, and system voltage levels can impact compatibility. The MSP430F532x microcontroller’s robust design ensures reliable performance in harsh industrial conditions, further enhancing its suitability for existing systems.

Exploring Development Tools and Software Support

The availability of proper software and hardware tools plays a critical role in the successful implementation of industrial automation projects. The MSP430F532x microcontroller benefits from Texas Instruments’ extensive development ecosystem, which includes tools for prototyping, testing, and optimization.

Industry benchmarks highlight the importance of evaluating development tools and software support systems. These evaluations provide several benefits:

-

Improve User Experience: Identifying performance issues early ensures a smooth user experience, keeping users engaged.

-

Reduced Development Costs: Addressing performance problems in the early stages is more cost-effective than fixing them later.

-

Enhanced Scalability: Benchmarks help understand application performance under various loads, crucial for future scalability.

-

Data-Driven Decision Making: Benchmarks provide data to guide development choices and resource allocation.

Texas Instruments offers a range of tools to support the MSP430F532x microcontroller. These include Code Composer Studio (CCS), an integrated development environment (IDE) that simplifies coding and debugging. Engineers can also access evaluation kits and reference designs to accelerate the development process. These resources enable developers to test their applications under real-world conditions, ensuring optimal performance.

Software libraries and middleware solutions further enhance the microcontroller’s capabilities. For example, pre-built libraries for communication protocols like USB and I2C reduce development time. Middleware simplifies the integration of automation technologies with existing systems, as seen in case studies involving collaborative robots in automotive assembly plants.

By leveraging these tools and resources, engineers can streamline the development process and ensure their applications meet industrial standards. The MSP430F532x microcontroller’s robust development ecosystem underscores its value as a versatile and efficient solution for industrial automation.

Comparing the MSP430F532x with Other Microcontrollers

Advantages of the MSP430F532x for Industrial Automation

The MSP430F532x microcontroller offers several advantages that make it a strong contender for industrial automation applications. Its ultra-low power consumption stands out as a key feature, enabling efficient operation in battery-powered systems. The microcontroller’s 16-bit RISC architecture ensures high processing efficiency, making it suitable for real-time data handling and control tasks. Additionally, its integrated communication interfaces, including SPI, UART, I2C, and USB, simplify connectivity with sensors and actuators.

The microcontroller’s flexible GPIO and peripheral options enhance its adaptability. With 47 GPIO pins and advanced features like timers and ADC channels, it supports diverse industrial requirements. Engineers can leverage these features to design systems tailored to specific needs. Furthermore, Texas Instruments provides robust development tools, such as Code Composer Studio and evaluation kits, which streamline prototyping and testing processes.

The MSP430F532x excels in environments requiring energy efficiency, scalability, and reliable communication. Its combination of features positions it as the best microcontroller for applications like sensor interfacing, motor control, and remote monitoring.

Situations Where Other Microcontrollers May Be Better

While the MSP430F532x microcontroller offers impressive features, certain scenarios may favor alternative microcontrollers. For example, applications requiring higher energy efficiency might benefit from devices like the MSP432P401x, which is based on an ARM Cortex-M4 architecture. This microcontroller is reported to be five times more energy efficient than MSP430 16-bit derivatives, making it ideal for power-sensitive systems.

Other microcontrollers, such as the STM32L476RG, also based on ARM Cortex-M4, provide competitive performance with a ULPBench result of 121. This makes them suitable for applications demanding both energy efficiency and processing power. Similarly, the Microchip PIC24FJ64GA202 demonstrates versatility with ULPBench results of 40 and 77.43, indicating its capability to handle diverse tasks effectively.

In contrast, older models like the MSP430FR5969 and MSP430FG4618 may struggle in terms of processing efficiency. The MSP430FR5969 achieved a ULPBench result of 121, which is decent but not exceptional for an FRAM device. The MSP430FG4618, with a ULPBench result of 31.74, highlights inefficiencies in its design, making it less suitable for demanding industrial applications.

Tip: Engineers should evaluate specific application requirements, such as energy efficiency, processing speed, and scalability, to determine the most suitable microcontroller for their projects.

Cost-Effectiveness and Long-Term Support

Cost-effectiveness plays a crucial role in microcontroller selection, especially for large-scale industrial deployments. The MSP430F532x microcontroller offers a balance between performance and affordability. Its energy-efficient design reduces operational costs over time, making it a cost-effective choice for battery-powered systems. Additionally, its robust development ecosystem minimizes design complexity, saving time and resources during implementation.

Long-term support is another critical factor. Texas Instruments provides extensive resources, including software libraries, reference designs, and technical documentation, ensuring engineers have the tools needed for successful development. The company’s commitment to product longevity ensures reliable support for industrial applications, reducing the risk of obsolescence.

Microcontrollers like the STM32L476RG and MSP432P401x may offer higher energy efficiency or processing power, but their cost and support structures should be carefully evaluated. Engineers must consider factors like initial investment, maintenance costs, and availability of development tools when selecting the best microcontroller for their needs.

Note: The MSP430F532x microcontroller’s combination of affordability, energy efficiency, and reliable support makes it a preferred choice for many industrial automation projects.

Prototyping and Testing the MSP430F532x Microcontroller

Setting Up a Development Environment

Setting up a proper development environment is the first step in prototyping with the MSP430F532x microcontroller. Engineers should begin by acquiring the necessary tools, such as Texas Instruments’ Code Composer Studio (CCS) and an MSP430F532x evaluation kit. These tools simplify the process of writing, debugging, and testing code. The evaluation kit provides a hardware platform for experimenting with the microcontroller’s features.

After installing CCS, engineers can configure the software to recognize the MSP430F532x. This involves selecting the correct device family and setting up the project workspace. Connecting the evaluation board to a computer via USB allows for seamless communication between the hardware and software. Engineers can then write and upload code to the microcontroller, enabling them to test various functionalities.

Testing Real-Time Performance and Power Consumption

Testing the microcontroller’s performance is crucial for ensuring it meets industrial automation requirements. Engineers can use benchmarking tools to measure processing speed and response times. For example, they can evaluate how quickly the MSP430F532x processes sensor data and executes control commands. These tests demonstrate the microcontroller’s ability to handle real-time tasks efficiently.

Power consumption testing is equally important. Engineers can measure current draw in different power modes, such as active and standby. Tools like EnergyMonitor provide accurate readings, helping engineers optimize energy usage. By analyzing these metrics, they can ensure the microcontroller operates efficiently without compromising performance.

Debugging and Optimizing for Industrial Applications

Debugging is an essential part of the development process. Engineers can use CCS’s built-in debugging tools to identify and resolve issues in their code. Breakpoints and step-by-step execution allow for detailed analysis of program behavior. This ensures the microcontroller performs as expected in industrial settings.

Optimization focuses on enhancing the microcontroller’s efficiency. Engineers can refine algorithms to reduce processing time and minimize power consumption. They can also adjust peripheral configurations to improve system performance. These efforts result in a reliable and efficient solution tailored to industrial automation needs.

Selecting the MSP430F532x microcontroller for industrial automation involves evaluating important factors to consider, such as processing power, memory capacity, and I/O peripherals. These elements ensure the microcontroller can handle complex tasks while maintaining cost efficiency. The growing demand for intelligent automation solutions highlights the relevance of this microcontroller in modern industrial settings.

Prototyping and testing play a vital role in achieving optimal performance. Engineers can use development tools to assess real-time processing and energy efficiency, ensuring the microcontroller meets application-specific needs. Leveraging its features, such as low power consumption and integrated communication modules, enables the creation of efficient and reliable automation systems. The MSP430F532x stands out as a versatile solution for industries seeking advanced automation capabilities.

What makes the MSP430F532x microcontroller suitable for industrial automation?

The MSP430F532x microcontroller offers ultra-low power consumption, a high-performance 16-bit RISC architecture, and integrated communication interfaces. These features ensure energy efficiency, real-time responsiveness, and seamless connectivity, making it ideal for industrial automation applications like motor control and sensor interfacing.

How does the MSP430F532x handle real-time data processing?

The MSP430F532x uses a 16-bit RISC architecture operating at up to 25 MHz. This design ensures fast instruction execution and low latency, enabling the microcontroller to process real-time data efficiently. Applications like robotics and IoT benefit from its rapid response capabilities.

What development tools are available for the MSP430F532x?

Texas Instruments provides Code Composer Studio (CCS), evaluation kits, and reference designs for the MSP430F532x. These tools simplify coding, debugging, and prototyping. Engineers can also access pre-built libraries for communication protocols like USB and I2C to accelerate development.

Can the MSP430F532x integrate with legacy systems?

Yes, the MSP430F532x supports integration with legacy systems through its SPI, UART, and I2C interfaces. Its low power consumption and robust design ensure compatibility with resource-constrained devices, making it suitable for modernizing existing industrial setups.

What are the power modes of the MSP430F532x microcontroller?

The MSP430F532x features active, standby, and off modes. Active mode consumes 290 µA/MHz, while standby mode uses only 1.9 µA at 2.2 V. These modes optimize energy usage, extending battery life and reducing operational costs in industrial applications.

See Also

Three Innovative Approaches of ATIC83E2 in Automation

Understanding MC9S12DJ256MFUE Specs for Automotive Use

SPC56 Microcontrollers: Simplified Solutions for Engine Control

Three Key Transformations of XCF01SVOG20C in Automation

ARTESYN NPT42-M: Energizing the Future of Automation