As an engineer with years of experience in the automotive electronics field, I have personally witnessed the evolution of the Powertrain Control Unit from simple logic to highly integrated and intelligent systems. In this technological revolution, STMicroelectronics’ SPC56 series microcontrollers are undoubtedly a key force driving advancements in engine control technology. They are not merely code executors on silicon chips but are the core “brains” enabling modern vehicles to achieve efficient, environmentally friendly, and safe driving.

The SPC56 Series: The Foundation of Automotive-Grade Microcontrollers

The SPC56 series microcontrollers, particularly L-series models like the SPC564L54L5 and SPC564L70L5, are designed specifically for harsh automotive environments. Based on the powerful Power Architecture® 32-bit core, they deliver exceptional computational performance and real-time responsiveness. This is crucial for engine control, as core functions like fuel injection, ignition timing, and emission management require millisecond-level precision. My team, while developing a new-generation engine management system, thoroughly evaluated and ultimately selected the SPC56 series due to its unparalleled performance, reliability, and deep support for functional safety.

Core Technical Highlights & Engineering Practice:

-

Power Architecture® 32-bit Core: This is the cornerstone of the SPC56 series’ performance. It provides not only powerful single or multi-core processing capabilities but, more importantly, its architecture balances real-time performance and determinism. In practical development, we leveraged its multi-core features to distribute complex control algorithms (such as intake models and combustion prediction) across different cores. This enhanced overall system throughput while guaranteeing response speed. For instance, one core can focus on sensor data acquisition and pre-processing, while another handles core PID control loops and fault diagnosis. This parallel processing capability significantly simplifies software architecture and improves system robustness.

-

Enhanced Time Processing Unit (eTPU) & DSP Capabilities: The eTPU is a major standout feature of the SPC56 series for engine control applications. It is a highly configurable co-processor capable of executing complex timing and I/O operations independently of the main CPU. In fuel injection systems, the eTPU can precisely generate Pulse Width Modulation (PWM) signals to control injector opening and closing times with nanosecond-level accuracy. We faced a challenge requiring multi-point sequential injection on a high-RPM engine, dynamically adjusting the injection strategy based on engine load and speed. The flexibility and DSP capabilities of the eTPU allowed us to easily implement these complex waveform generation and signal processing tasks, greatly offloading the main CPU to focus on higher-level control logic. This hardware acceleration capability is vital for improving engine fuel economy and reducing emissions.

-

Functional Safety & ASIL-D Certification: Functional safety requirements in the automotive industry are increasingly stringent, and the SPC56 series excels in this area. Built-in Memory Error Correction Code (ECC) protection and the Fault Collection and Control Unit (FCCU) are key to achieving ASIL-D (Automotive Safety Integrity Level D). In actual project deployments, we utilized these hardware safety mechanisms to build multi-layered software safety strategies. For example, ECC allows real-time detection and correction of single-bit errors in RAM, preventing control failures due to data corruption. The FCCU monitors various internal system faults and triggers safety mechanisms (like entering a safe mode or disabling relevant functions) upon detecting anomalies, ensuring the safety of the vehicle and occupants. This comprehensive safety consideration, from hardware to software, was a significant reason for choosing the SPC56 series, especially when developing critical systems like steer-by-wire or brake-by-wire.

-

Rich Set of In-Vehicle Network Interfaces: Modern vehicles are highly interconnected systems, and in-vehicle networks like CAN, LIN, and FlexRay are the communication bridges between ECUs. The SPC56 series integrates various communication interfaces, such as LINFlex and FlexCAN, enabling seamless integration into existing automotive electronic architectures. During the development of an on-board diagnostic system, we used the FlexCAN interface of the SPC56 to achieve high-speed data exchange with other vehicle ECUs (like transmission and body controllers), enabling more comprehensive fault diagnosis and data logging functions. Its compatibility significantly shortened our integration and testing cycles.

Practical Application Cases & Experience Sharing

Case 1: High-Precision Fuel Injection Control

In a diesel engine management project, the challenge was achieving precise control of ultra-high-pressure common rail injection under various operating conditions to meet stringent Euro VI emission standards. The multi-core processing capability of the SPC564L70L5 allowed us to run complex combustion models and injection strategies in parallel. The eTPU was responsible for driving piezoelectric injectors, enabling up to seven injections per cycle, with the duration and interval of each injection precisely adjustable at the microsecond level. Leveraging the powerful features of the SPC56, we successfully reduced NOx and particulate matter emissions by over 15% while improving fuel economy by approximately 5%.

Case 2: Energy Management in Hybrid Electric Vehicles (HEVs)

In the development of a Hybrid Electric Vehicle (HEV), the Battery Management System (BMS) and Motor Control Unit (MCU) need close coordination with the Engine ECU to optimize energy distribution. Using the SPC56 microcontroller as the core of the Engine ECU, it exchanged critical information such as battery status and motor torque demands with the BMS and MCU in real-time via its high-speed CAN bus interface. We utilized the SPC56’s Real-Time Operating System (RTOS) and robust interrupt handling capabilities to ensure engine start-stop, torque coordination, and mode switching were completed within milliseconds, providing a smooth and efficient driving experience. This seamless integration is fundamental for implementing the complex energy management strategies of HEVs.

Case 3: Extending Functional Safety to Autonomous Driving

Although primarily used in powertrains, the functional safety features of the SPC56 also provide valuable experience for the development of autonomous driving systems. When developing a redundant braking system for an autonomous vehicle, we applied the design principles learned from the SPC56’s ECC and FCCU to build independent fault detection and safe degradation mechanisms. This ensured that even if the primary braking system failed, the redundant system could intervene promptly to bring the vehicle to a safe stop. This cross-domain reuse of experience highlights the forward-thinking nature of the SPC56 series in automotive electronic safety design.

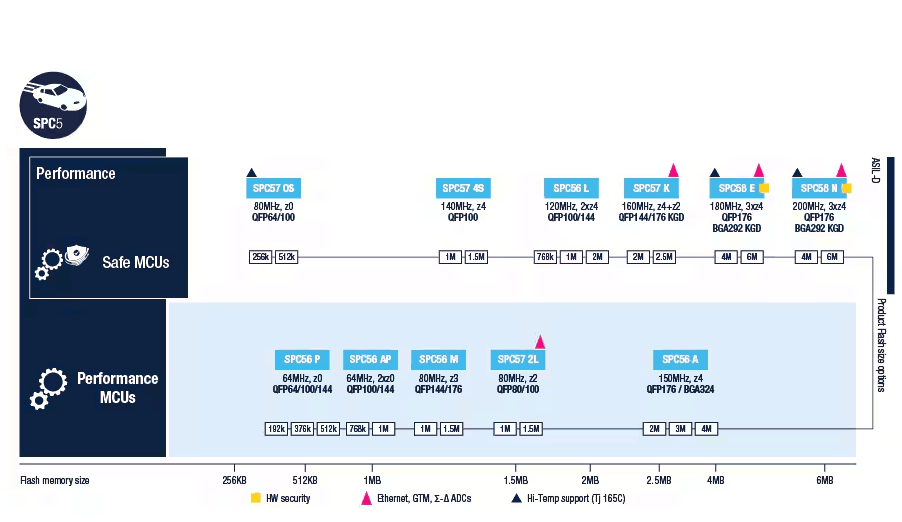

Future Outlook: The Continuous Evolution of SPC56

STMicroelectronics provides a product longevity commitment of up to 20 years for the SPC56 series. This means manufacturers can confidently use it in long-term projects without worrying about supply chain disruptions or overly rapid technological obsolescence. Such a commitment is crucial for the automotive industry, where a vehicle platform’s lifecycle can often span decades. Furthermore, the software compatibility between the SPC56 series and ST’s next-generation SPC58 series microcontrollers provides a smooth path for future upgrades and expansions. This means a significant portion of the software development and verification effort invested in the SPC56 platform can be reused for future new platforms, protecting our initial investment.

Conclusion

SPC56 microcontrollers are not just high-performance computing chips; they are reliable partners for automotive engineers facing increasingly complex engine control challenges. With their exceptional performance, robust functional safety support, and flexible integration capabilities, they continuously drive innovation in automotive powertrain technology. As an engineer, I understand the importance of selecting the right hardware platform for project success. The SPC56 series, with its proven stability in practical applications and its forward-looking design, is undoubtedly an ideal choice for building the intelligent, efficient, and safe vehicles of the future. I look forward to seeing more innovative solutions based on the SPC56 that will continue to transform the automotive industry.

See Also

Key Features of SPC5605BMLL6 and SPC5607BMLL6 ECUs

Discovering MC9S12DJ256MFUE Specs for Auto Use

Best Methods for MC9S12XET512VAG Integration

Simple Guide to Integrating SN74LVC4245APW Sensors

Guide to Installing ATA5824C in Remote Controls