TCMT1103 Tips for Safe Motor Control

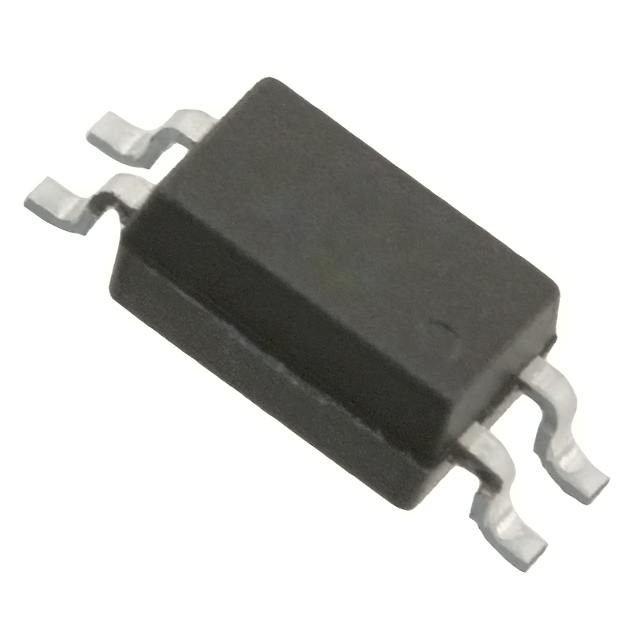

Ensuring safe motor control is crucial across various applications, as it guarantees that equipment functions reliably and securely. Understanding the significance of functional safety is essential, particularly in environments where equipment failure can present substantial risks. The TCMT1103, a single-channel optoisolator from Vishay, emerges as a vital component for achieving safety and reliability in motor control systems. This transistor-based device offers electrical isolation between control and power circuits, making it an ideal choice for both motor control and medical devices. By comprehending the features and setup of the TCMT1103, you can effectively implement it for motor control applications.

Understanding TCMT1103

Key Features of TCMT1103

Overview of its capabilities

The TCMT1103 from Vishay stands out as a versatile component in the realm of motor control. This single-channel optoisolator integrates advanced microcontroller technology, consolidating processing power, memory storage, and input/output interfaces into a compact design. You will find that this integration simplifies the development process, ensuring optimal performance across various applications. The TCMT1103 can withstand high isolation voltages, making it suitable for environments where electrical isolation is crucial. Its transistor output provides reliable signal transmission, which is essential for maintaining the integrity of control signals in high-voltage settings.

Benefits for motor control applications

In motor control applications, the TCMT1103 offers significant benefits. It provides electrical isolation between control and power circuits, ensuring safe operation and protecting sensitive components from high-power motor operations. You can rely on its ability to prevent interference, enhancing noise immunity and ensuring smooth motor function. The compact 4-SOP package allows for easy integration into various designs, making it a practical choice for engineers seeking efficient solutions.

Advantages of Using TCMT1103

Reliability and efficiency

When you use the TCMT1103, you gain access to a component known for its reliability and efficiency. Its design ensures consistent performance, reducing the risk of equipment failure. The TCMT1103 enhances system reliability by isolating control signals from power electronics, which is vital in maintaining the safety and longevity of motor control systems. This optoisolator's efficiency lies in its ability to handle high voltages while maintaining signal integrity, making it an indispensable tool in your motor control toolkit.

Compatibility with various systems

The TCMT1103 offers broad compatibility with different systems, making it a flexible choice for diverse applications. Whether you are working on industrial automation, consumer electronics, or telecommunications, this component adapts seamlessly to your needs. Its versatility extends to data acquisition systems and medical devices, where electrical isolation is paramount. By choosing the TCMT1103, you ensure that your projects benefit from a component that meets the demands of modern electronic designs.

Step-by-Step Guide to Implementing TCMT1103

Implementing the TCMT1103 in your motor control system involves a series of straightforward steps. This guide will help you set up and configure the device for optimal performance.

Initial Setup and Configuration

Required tools and components

To begin, gather the necessary tools and components. You will need the TCMT1103 optoisolator, a compatible microcontroller, and a power supply. Ensure you have a soldering iron, multimeter, and appropriate connectors. These tools will assist you in assembling and testing the circuit.

Basic installation steps

Start by connecting the TCMT1103 to your microcontroller. Solder the optoisolator's input pins to the microcontroller's output pins. Connect the output pins to the motor control circuit. Verify all connections with a multimeter to ensure proper continuity. Power up the system and check for any irregularities. This basic setup prepares the TCMT1103 for further configuration.

Configuration for Optimal Performance

Adjusting settings for specific applications

Fine-tuning the TCMT1103 settings enhances its performance in specific applications. Adjust the input current to match the requirements of your motor control system. Modify the output voltage levels to ensure compatibility with connected devices. These adjustments optimize the TCMT1103 for various environments, including industrial automation and medical devices.

Testing and validation procedures

Testing and validation are crucial to confirm the TCMT1103's functionality. Conduct a series of tests to evaluate signal integrity and isolation performance. Use a multimeter to measure voltage levels and ensure they meet expected values. Validate the system by running the motor control application under different conditions. This process ensures the TCMT1103 operates reliably and safely.

Safety Tips and Best Practices

Common Pitfalls to Avoid

Misconfigurations and their consequences

Misconfigurations in motor control systems can lead to severe consequences. You must ensure that all settings align with the specific requirements of your application. Incorrect configurations can cause system failures, leading to costly downtime or even equipment damage. For instance, setting the wrong input current or output voltage levels can result in inefficient performance or overheating. Always double-check your configurations to prevent these issues.

Overlooking safety protocols

Safety protocols exist to protect both the equipment and the operator. Ignoring these protocols can compromise the entire system's safety. You should always adhere to established safety measures like Safety Torque Off and Emergency Stop. These features are crucial for maintaining operational integrity and preventing accidents. Regularly review and update your safety protocols to ensure they meet current standards.

Ensuring Long-term Reliability

Regular maintenance and checks

Regular maintenance is vital for the long-term reliability of motor control systems. You should schedule routine checks to identify and address potential issues before they escalate. Inspect all components, including the TCMT1103, for signs of wear or damage. Conduct hardware-based fault diagnostics to ensure everything functions correctly. Consistent maintenance helps extend the lifespan of your equipment and ensures continuous operation.

Updating firmware and software

Keeping your firmware and software up to date is essential for optimal performance. Updates often include enhancements that improve system reliability and safety. You should regularly check for updates from the manufacturer and apply them promptly. This practice not only enhances functionality but also addresses any security vulnerabilities. By staying current with updates, you ensure that your motor control system operates at its best.

Understanding the TCMT1103's features and setup is crucial for ensuring safe motor control. You gain a compact and efficient solution for electronic devices of all sizes. By following safety tips and best practices, you protect your equipment and enhance its reliability. Apply these insights to improve motor control safety in your projects. Explore further learning opportunities and implement these strategies to achieve optimal results.

See Also

Understanding The IRF820 MOSFET For Power Applications

Enhancing Process Control With AD74413RBCPZ Insights

SPC56 Microcontrollers: Simplified Solutions For Engine Control

CALL US DIRECTLY

(+86)755-82724686

RM2508,BlockA,JiaheHuaqiangBuilding,ShenNanMiddleRd,Futian District,Shenzhen,518031,CN

www.keepboomingtech.com sales@keepboomingtech.com