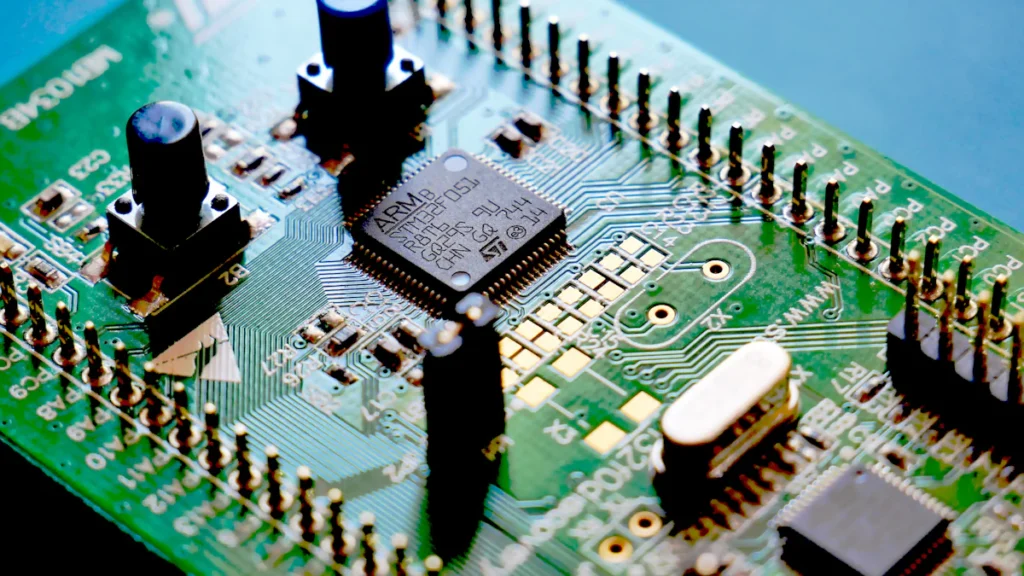

In the complex world of modern automotive electronics, microcontrollers play a pivotal role. Among them, the MC9S12XET512VAG series microcontroller from NXP has secured its position in Automotive Electronic Control Unit (ECU) design, thanks to its robust processing capabilities, abundant on-chip resources, and exceptional real-time performance. As an engineer with years of deep experience in the automotive electronics field, I have witnessed firsthand how the MC9S12XET512VAG evolved from a mere chip model into the core driving force behind numerous innovative automotive functions. From a professional engineer’s perspective, this article will delve into three mainstream integration strategies for the MC9S12XET512VAG within automotive systems. Combined with practical application cases and experiential insights, it aims to provide you with more profound and practical understanding.

MC9S12XET512VAG: The “Brain” of Automotive Electronics

The MC9S12XET512VAG belongs to NXP’s S12X family, based on an enhanced HCS12X core, and integrates 512KB of Flash, 32KB of RAM, and a rich set of communication interfaces (such as CAN, LIN, SPI, SCI). Its core advantages include:

-

Real-Time Performance & Reliability: Designed specifically for automotive applications, it offers excellent real-time response capabilities, meeting the stringent timing requirements of applications like engine management and brake systems (ABS/ESC).

-

Powerful Processing Capability: The 16-bit CPU, coupled with the XGATE co-processor, efficiently handles complex control algorithms and data streams, excelling particularly in multi-tasking and parallel processing.

-

Rich Communication Interfaces: Support for multiple automotive bus protocols ensures seamless communication with other ECUs, sensors, and actuators within the vehicle.

-

High Integration & Cost-Effectiveness: The high level of peripheral integration on-chip reduces the number of external components, lowering system cost and PCB footprint.

Understanding these fundamental characteristics is the cornerstone for discussing its integration strategies. In practical projects, the choice of integration method often depends on project requirements, cost constraints, development timelines, and system complexity.

Strategy 1: Direct Integration – The Art of Balancing Efficiency and Cost

Core Concept: Direct Integration involves embedding the MC9S12XET512VAG microcontroller directly into the existing hardware and software architecture of an Automotive ECU, making it the core executor of the ECU’s functions. This approach is typically suitable for scenarios with strict cost and development cycle constraints, and where the existing system architecture is relatively fixed.

Technical Points & Practice:

-

Hardware Level:

-

PCB Layout & Signal Integrity: When designing the ECU, special attention must be paid to the Power Integrity and Signal Integrity of the MC9S12XET512VAG. High-speed signal lines (e.g., clock, data lines) should employ impedance matching and differential pair routing to minimize Electromagnetic Interference (EMI) and crosstalk. For instance, in an engine ECU, power-stage components (like IGBT drivers) surrounding the microcontroller generate significant noise, making a proper grounding scheme (e.g., star ground or multi-point ground) and the configuration of decoupling capacitors crucial.

-

Interface Matching: Ensure the electrical characteristics and protocols of the MC9S12XET512VAG’s interfaces (CAN, LIN, SPI, etc.) fully match those of other chips in the ECU (e.g., sensor interface chips, power driver chips). For example, the configuration of CAN bus termination resistors and the selection of LIN bus single-wire transceivers must strictly adhere to specifications.

-

-

Software Level:

-

Low-Level Driver Development: It is necessary to write low-level drivers (HAL layer) targeting the specific registers and peripherals of the MC9S12XET512VAG to achieve precise control over functions like GPIO, Timers, ADC, and PWM. This often involves register manipulation using Assembly or C language.

-

Legacy Code Porting & Adaptation: Port the ECU’s existing control algorithms and application logic to the MC9S12XET512VAG development environment. This may require code optimization to fit the microcontroller’s limited memory and processing resources. For example, replacing floating-point arithmetic with fixed-point arithmetic can enhance execution efficiency.

-

Practical Application Case:

I was involved in an upgrade project for a legacy vehicle model’s powertrain ECU. The original system used an older microcontroller whose performance could no longer meet new emission standards and diagnostic requirements. The decision was made to directly replace it with the MC9S12XET512VAG. Through careful PCB layout design and optimized low-level drivers, we successfully enhanced engine control precision and response speed, and added OBD-II diagnostic functionality, all without major modifications to the ECU housing and connectors. The challenge lay in the incomplete pin compatibility between the old and new microcontrollers, requiring meticulous hardware adaptation and software refactoring. However, this approach ultimately saved the significant cost associated with completely redeveloping the entire ECU.

See Also

Detailed Walkthrough of AD620AN for TV Power Usage

The Secret Behind Technology’s Excellence in Electronics