Capacitors play a vital role in electronic circuits by addressing critical challenges such as noise filtering, energy storage, and voltage regulation. Their ability to store and release electrical energy makes them indispensable in modern devices, from smartphones to industrial machinery. Different types of capacitors, each with unique properties, are designed to meet specific circuit requirements. For example, ceramic capacitors excel in high-frequency applications, while aluminum electrolytic capacitors provide effective decoupling at lower frequencies. As a leading capacitors distributor, we ensure that engineers and designers have access to a wide variety of capacitor types to enhance circuit stability and efficiency. Recent advancements, like hybrid electrochemical capacitors, demonstrate their growing importance in filtering noise across frequencies from 1 to 10,000 Hz. These innovations help circuits achieve precise filtering and voltage stabilization, proving their versatility in electronic design.

Key Takeaways

-

Capacitors help keep voltage steady, block noise, and store energy.

-

Picking the right capacitor, like ceramic for fast signals or electrolytic for storing energy, makes circuits work better.

-

Capacitors save energy by cutting power waste and keeping power steady.

-

Knowing how each capacitor works helps engineers make better designs.

-

New types, like polymer capacitors, handle high currents and work well in tough jobs.

What Are Capacitors and Why Are They Important in Circuit Design?

The Basic Function of a Capacitor

Capacitors store and release electrical energy by utilizing an electric field created between two conductive plates separated by a dielectric material. This process allows capacitors to absorb transient spikes and provide stable power to components on a printed circuit board (PCB). Their capacitance value, determined by the geometry of the plates and the dielectric material, dictates the amount of charge they can store. Capacitors also play a vital role in eliminating DC components during audio signal amplification, ensuring cleaner sound output.

Capacitors are essential in LC and RC oscillators, where they generate waveforms for signal processing and frequency modulation. Their ability to store and release energy at precise intervals ensures stable frequency output, making them indispensable in applications like function generators and FM systems.

Key Roles of Capacitors in Electronics

Capacitors perform several critical functions in electronic systems:

-

Noise Filtering: They reduce unwanted signals, ensuring clearer communication in telecommunications.

-

Energy Storage: Capacitors provide backup power during transient events, stabilizing circuits in industrial machinery and automotive electronics.

-

Voltage Regulation: They smooth voltage fluctuations, enhancing the efficiency of medical equipment and aerospace systems.

-

Signal Processing: Capacitors improve signal clarity in high-frequency circuits, benefiting research labs and smart grids.

Modern advancements highlight their importance. For instance, Panasonic’s ZV Series capacitors offer up to 50% higher ripple current compared to competitors, while ROHM’s silicon capacitors utilize RASMID™ technology for miniaturization, improving dimensional tolerances.

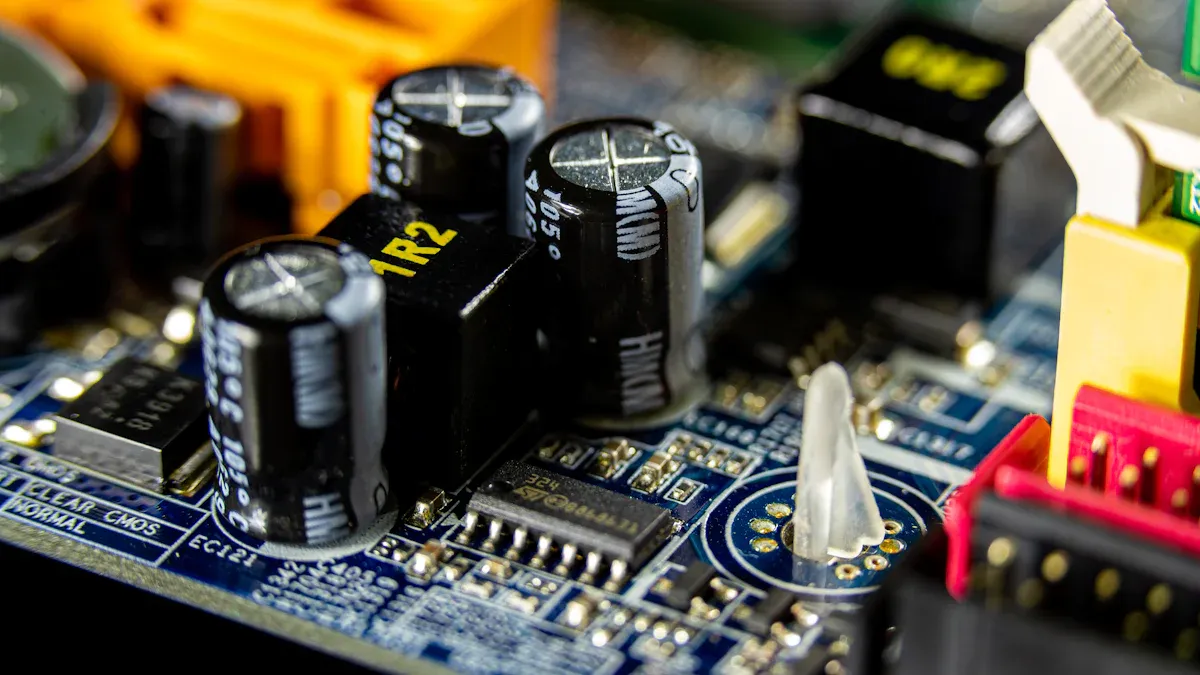

Why Capacitors Are Critical for Circuit Stability and Efficiency

Capacitors contribute significantly to circuit stability and efficiency across various applications. In telecommunications, they filter noise, ensuring uninterrupted signal transmission. Industrial machinery benefits from capacitors in motor start circuits, reducing energy consumption and enhancing performance. Automotive electronics rely on capacitors to stabilize voltage for critical components, improving overall system reliability.

|

Application Area |

Contribution to Stability and Efficiency |

|---|---|

|

Telecommunications |

Filters noise, leading to clearer signal transmission and reduced interference. |

|

Industrial Machinery |

Improves motor start circuits, reducing energy usage and enhancing performance. |

|

Automotive Electronics |

Stabilizes voltage for critical components, improving overall system efficiency. |

|

Medical Equipment |

Ensures stable operation in critical conditions, enhancing reliability and safety. |

|

Aerospace Projects |

Maintains stability under extreme conditions, ensuring reliable power delivery. |

|

Research Labs |

Optimizes high-frequency circuits, resulting in superior signal clarity. |

|

Smart Grids |

Enhances energy distribution efficiency and grid stability. |

|

Household Appliances |

Boosts efficiency and reduces power consumption, leading to significant energy savings. |

High-heat capacitors, such as those made with SABIC’s ELCRES™ HTV150A films, demonstrate stable performance under extreme conditions, adhering to stringent industry standards like AEC-Q200. These innovations underscore the indispensable role capacitors play in modern electronics.

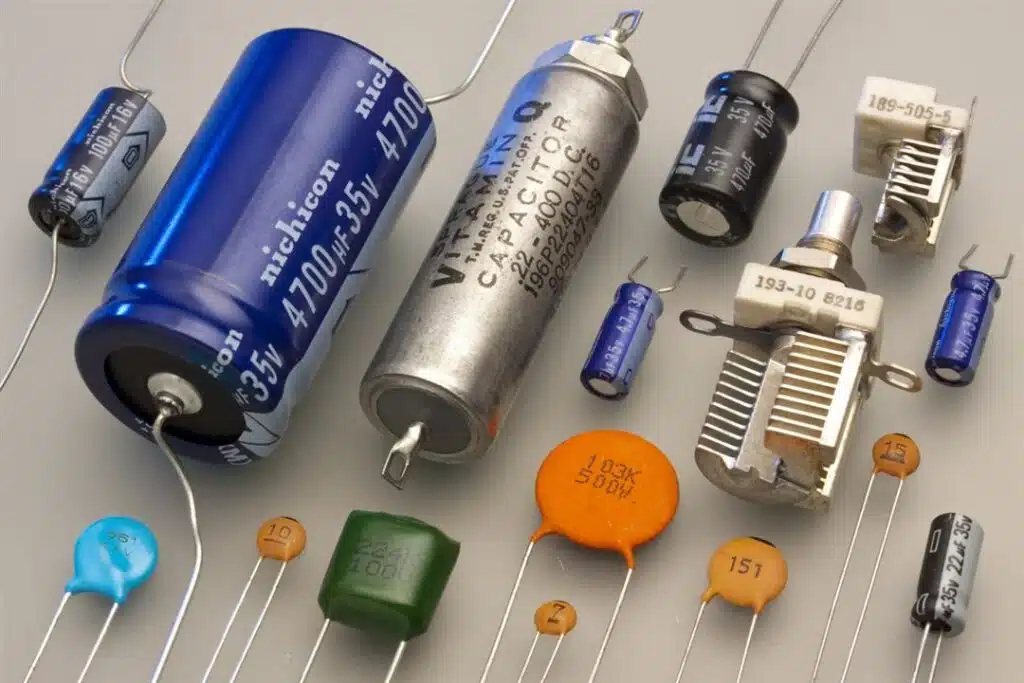

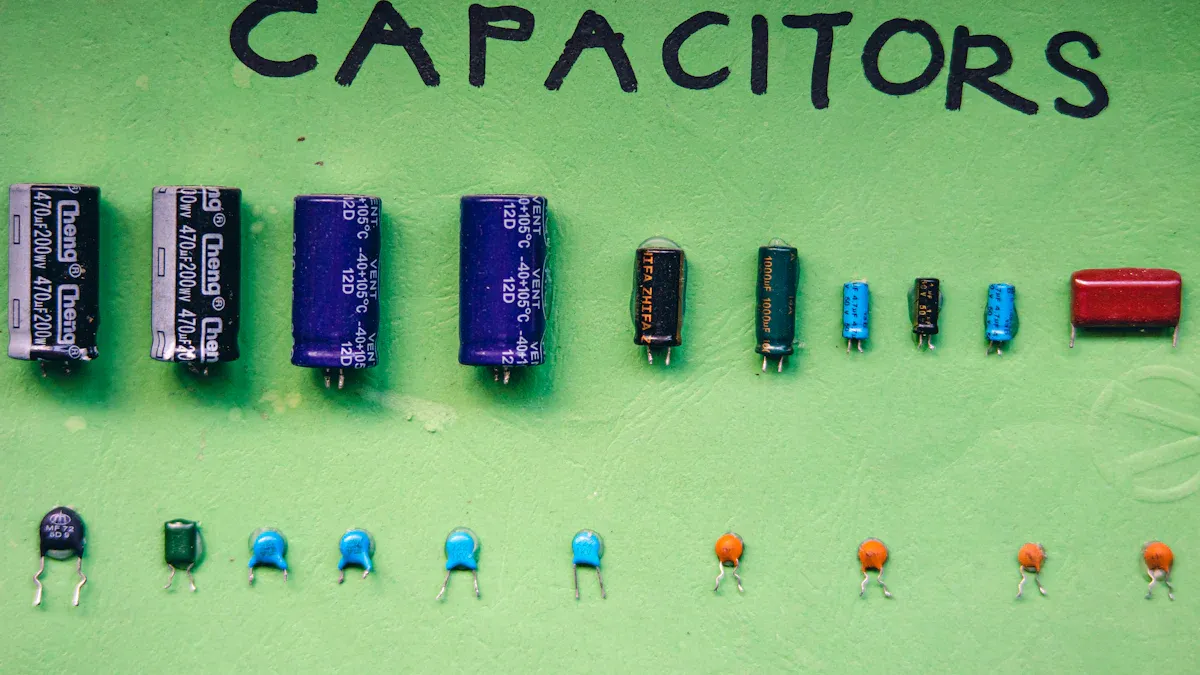

Types of Capacitors and Their Unique Properties

Ceramic Capacitors: High-Frequency Performance

Ceramic capacitors are among the most widely used types of capacitors due to their excellent high-frequency performance and compact size. These capacitors utilize a ceramic material as the dielectric, which provides low equivalent series resistance (ESR) and minimal DC leakage. This makes them ideal for applications requiring high-frequency noise filtering and decoupling.

Tip: Multi-layer ceramic capacitors (MLCCs) are particularly effective in high-speed circuits, where they stabilize voltage and suppress electromagnetic interference (EMI).

Ceramic capacitors are available in various temperature coefficients, such as X7R, X5R, and C0G/NP0. X7R and X5R are suitable for general-purpose applications, while C0G/NP0 offers high precision and stability, making it ideal for timing and oscillator circuits. For instance, MLCCs like Murata’s GRM series and Samsung’s CL series are commonly used in consumer electronics and automotive systems.

|

Capacitor Type |

Frequency Performance |

Capacitance Range |

|---|---|---|

|

MLCC (CT4, CT42) |

Optimal for low frequencies |

Stable capacitance |

|

MLCC (CC4, CC42) |

Excels in high frequencies |

High-speed applications |

Ceramic capacitors are also cost-effective and available in surface-mount designs, making them a preferred choice for compact devices like smartphones and laptops.

Electrolytic Capacitors: High Capacitance for Energy Storage

Electrolytic capacitors are known for their high capacitance values, which make them indispensable in circuits requiring energy storage and voltage smoothing. These capacitors use an electrolyte as one of their plates, allowing them to achieve capacitance ratings far higher than other types of capacitors.

Note: Aluminum electrolytic capacitors are commonly used in power supply circuits to filter and stabilize voltage.

Electrolytic capacitors are available in various case sizes and capacitance ratings. For example, a 1206 case size can provide a capacitance of 100μF, while larger sizes like 2924 can reach up to 2.2mF. These capacitors are particularly effective in automotive electronics, industrial machinery, and audio equipment.

|

Case Size (EIA) |

Capacitance Rating |

|---|---|

|

1206 (3.2mm x 1.6mm) |

100μF |

|

2924 (7.3mm x 6.1mm) |

2.2mF |

Although electrolytic capacitors have higher ESR compared to ceramic capacitors, their stability and energy storage capabilities make them essential for bulk filtering in power supplies. Panasonic’s EEU-FR series and Nichicon’s UHE series are examples of reliable electrolytic capacitors designed for long life and high performance.

Film Capacitors: Stability and Precision

Film capacitors are celebrated for their exceptional stability and precision. These capacitors use a thin plastic film as the dielectric, which provides high insulation resistance and low energy loss. Their ability to maintain consistent performance over time makes them ideal for applications requiring reliability and accuracy.

Film capacitors are versatile and find use in various industries, including automotive, industrial, and audio systems. For example, WIMA’s MKP series and Panasonic’s ECW series are popular choices for power filtering and EMI suppression. These capacitors are also used in AC circuits and high-stability applications.

|

Testing Method |

Description |

|---|---|

|

Burn-In Testing |

Involves subjecting capacitors to elevated voltage and temperature for specified durations to identify defects. |

|

Failure Modes |

Identifies how capacitors fail under stress, including loss of resistivity and degradation of capacitance. |

|

Pre-Test Data |

Electrical properties are measured before burn-in to compare with post burn-in data for reliability assessment. |

Film capacitors are larger than ceramic capacitors due to their lower dielectric constant. However, their wide range of material specifications allows engineers to select the most suitable option for their designs. Their low ESR and high voltage ratings make them a preferred choice for demanding applications.

Tantalum Capacitors: Compact and Reliable

Tantalum capacitors are highly valued for their compact size and exceptional reliability. These capacitors use tantalum as the primary material for their electrodes, which allows them to achieve high volumetric efficiency. This makes them ideal for applications where space is limited, such as in smartphones, medical devices, and aerospace systems.

Tip: Tantalum capacitors are particularly effective in circuits requiring stable performance under extreme conditions, such as automotive and industrial environments.

Their ability to operate reliably in harsh environments stems from their robust design. These capacitors maintain stability even under high temperatures and voltages, making them suitable for critical applications like electric vehicles (EVs). Newer series of tantalum capacitors offer enhanced temperature tolerance, ensuring consistent performance in demanding scenarios.

|

Performance Aspect |

Description |

|---|---|

|

High Volumetric Efficiency |

Provides superior capacitance in a small footprint, enhancing their compact design. |

|

Robustness in Harsh Environments |

Operates reliably in extreme conditions, suitable for critical applications. |

|

Enhanced Temperature Tolerance |

Offers improved stability under high voltages, especially in electric vehicle applications. |

Tantalum capacitors are also known for their low equivalent series resistance (ESR), which ensures efficient energy transfer and minimal power loss. This characteristic makes them a preferred choice for decoupling and filtering applications in high-performance circuits. Popular series like AVX’s TPS and Kemet’s T491 are widely used in surface-mount designs, offering both reliability and ease of integration.

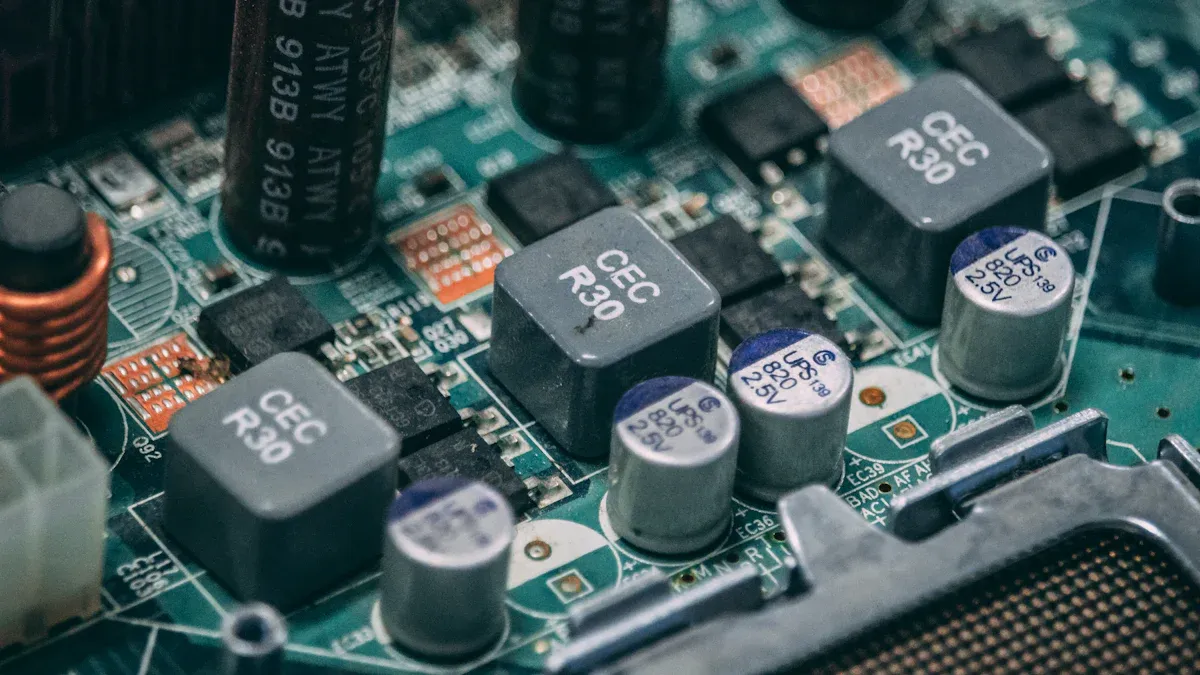

Conductive Polymer Capacitors: Ultra-Low ESR and High-Frequency Stability

Conductive polymer capacitors are a modern innovation designed to meet the demands of high-frequency and high-reliability applications. These capacitors use a conductive polymer as the electrolyte, which significantly reduces ESR compared to traditional electrolytic capacitors. This ultra-low ESR enhances their performance in circuits requiring high ripple current handling and stable capacitance over a wide temperature range.

Note: Conductive polymer capacitors are ideal for applications in automotive, industrial, and computing systems, where stability and efficiency are critical.

Key features of conductive polymer capacitors include stable capacitance values at high temperatures, high voltage ratings, and low leakage current. Their ability to maintain performance across a broad temperature range makes them suitable for use in power supplies, motor drives, and telecommunications equipment.

-

Low ESR: Ensures minimal energy loss and efficient power delivery.

-

High Ripple Current Characteristics: Supports stable operation in high-frequency circuits.

-

High Lifetime Performance: Offers long-term reliability, even under demanding conditions.

These capacitors are also valued for their compact design, which allows them to be integrated into space-constrained devices. For example, Panasonic’s POSCAP series and Nichicon’s FPCAP series are widely recognized for their high-frequency stability and durability. Engineers often choose conductive polymer capacitors for automotive electronics and industrial control systems, where consistent performance is essential.

Common Circuit Design Challenges

Filtering Noise and Unwanted Signals

Noise and unwanted signals are among the most common issues with capacitors in electronic systems. These disturbances can degrade circuit performance by introducing errors or interfering with signal clarity. Capacitors play a critical role in mitigating these problems. By stabilizing voltage and filtering out unwanted frequencies, they ensure smoother operation in capacitor application circuits.

RC filters, which combine resistors and capacitors, are particularly effective in eliminating noise. These filters remove high-frequency disturbances while allowing desired signals to pass through. For instance, audio systems rely on capacitors to filter out electrical noise, ensuring clear sound output. Capacitors also suppress electromagnetic interference (EMI), which is crucial in telecommunications and industrial electronics.

Tip: Decoupling capacitors placed near integrated circuits (ICs) can further reduce noise by isolating sensitive components from power supply fluctuations.

Storing Energy for Power Backup

Energy storage is another critical function of capacitors in circuit design. During power interruptions or transient events, capacitors act as temporary energy reservoirs. This capability ensures that circuits continue operating without disruption, even during brief power outages.

Bulk capacitors are commonly used for this purpose. They maintain stable voltage levels and support peak current demands in capacitor application circuits. For example, in automotive electronics, capacitors provide backup power to critical systems like airbags and anti-lock braking systems. Their ability to store and release energy rapidly makes them indispensable in high-performance circuits.

|

Challenge |

Solution |

|---|---|

|

Noise Filtering |

Incorporate filtering components and decoupling capacitors to suppress unwanted signals and noise. |

|

Voltage Regulation |

Proper shielding and filtering are essential to mitigate electromagnetic interference (EMI). |

Regulating Voltage for Stable Operation

Voltage regulation is essential for maintaining consistent circuit performance. Capacitors help achieve this by smoothing out voltage fluctuations and reducing ripple in power supplies. This ensures that sensitive components receive a stable power supply, which is vital for their longevity and reliability.

Decoupling capacitors are particularly effective in this role. They act as temporary energy storage devices, reducing source impedance and handling current peaks. Bulk capacitors complement this by maintaining stable voltage during power line interruptions. Together, these capacitors enhance circuit performance and prevent damage caused by voltage instability.

|

Role of Capacitors |

Description |

|---|---|

|

Bulk Capacitors |

Used to maintain stable voltage during power line interruptions and support peak current demands. |

|

Decoupling Capacitors |

Act as temporary energy storage to reduce source impedance, crucial for handling current peaks. |

Capacitors also minimize capacitor leakage, which can otherwise lead to inefficiencies in circuit design. By selecting the right type of capacitor for the application, engineers can ensure optimal performance and reliability.

Coupling and Decoupling in Signal Processing

Coupling and decoupling are essential techniques in signal processing, ensuring smooth signal transmission and stable circuit operation. Coupling capacitors allow AC signals to pass between circuit stages while blocking DC components. This prevents unwanted DC bias from interfering with sensitive components. Decoupling capacitors, on the other hand, stabilize power supply lines by filtering out noise and voltage fluctuations.

In practical applications, coupling capacitors are often placed between amplifier stages to maintain signal integrity. For example, in audio systems, they ensure that only the desired audio frequencies are transmitted, eliminating DC offsets. Decoupling capacitors are strategically positioned near integrated circuits (ICs) to reduce noise caused by sudden current demands. This placement minimizes voltage dips and ensures consistent performance.

Experimental data highlights the effectiveness of capacitors in coupling and decoupling. For instance, a study measured a coupling coefficient of 0.4 and mutual inductance of 6.97 nH, demonstrating efficient energy transfer. The use of a 390 pF capacitor reduced anti-resonance peaks by 3.2 times, enhancing signal clarity.

|

Parameter |

Value |

|---|---|

|

Resolution Band Width (RBW) |

10 Hz |

|

Number of Points |

1000 |

|

Power |

-15 dBm |

|

Distance Between Loops |

1 mm |

|

Coupling Coefficient (k) |

0.4 |

|

Inductance (L) |

17.6 nH |

|

Mutual Inductance (M) |

6.97 nH |

|

Capacitance (changed) |

390 pF (measured 380 pF) |

|

Anti-resonance Peak Reduction |

3.2 times lower for positive coupling |

By selecting the right type of capacitor, engineers can optimize coupling and decoupling for specific applications, ensuring reliable and efficient circuit performance.

Timing and Oscillation in Circuits

Capacitors play a pivotal role in timing and oscillation circuits, enabling precise control over signal generation and propagation. In timing circuits, capacitors work with resistors to create predictable time delays. The time constant (τ), calculated as τ = R × C, determines how quickly a capacitor charges or discharges. This characteristic is crucial for applications like clock generation and pulse-width modulation.

-

The time constant defines the charging and discharging rate of a capacitor.

-

It directly impacts the timing accuracy in circuits requiring precise control.

-

Engineers rely on this property for designing oscillators and delay circuits.

In oscillation circuits, capacitors contribute to generating stable waveforms. LC and RC oscillators use capacitors to store and release energy at specific intervals, maintaining consistent frequency outputs. This functionality is vital for applications such as frequency modulation and signal processing.

Load capacitance significantly affects frequency response and signal propagation delay. Minor variations in delay can lead to timing issues in high-speed digital circuits. In analog circuits, excessive capacitance may degrade signal integrity, introducing noise and distortion. Engineers must carefully balance capacitance values to achieve optimal performance.

Capacitors ensure reliable operation in both digital and analog systems. Their ability to influence timing and oscillation makes them indispensable in modern electronics, from microcontrollers to communication devices.

How Different Capacitor Types Solve Circuit Design Challenges

Ceramic Capacitors for High-Frequency Noise Filtering

Ceramic capacitors excel in high-frequency noise filtering due to their unique properties. These capacitors use ceramic as the dielectric material, which provides low equivalent series resistance (ESR) and inductance. Their compact size and high resonant frequencies make them ideal for applications requiring efficient noise suppression and decoupling.

Tip: Multi-layer ceramic capacitors (MLCCs) are particularly effective in high-speed circuits, where they stabilize voltage and suppress electromagnetic interference (EMI).

Engineers often choose ceramic capacitors for their stability and reliability in demanding environments. For example, X7R-type capacitors maintain minimal capacitance change under DC bias, ensuring consistent performance. These capacitors also operate effectively across a wide temperature range, making them suitable for automotive and industrial applications.

|

Metric |

Description |

|---|---|

|

Low Inductance |

Ceramic capacitors have low inductance, which is crucial for high-frequency applications. |

|

High Resonant Frequencies |

They possess high resonant frequencies, enabling effective filtering of high-frequency noise. |

|

Decoupling Capability |

Used to decouple high-frequency power supply noise, enhancing circuit stability. |

|

Compact Size |

Their compact nature allows for efficient use in circuit design. |

|

Low Loss |

Ceramic capacitors exhibit low loss characteristics, improving overall performance. |

|

Wide Temperature Tolerance |

They can operate effectively across a wide range of temperatures. |

|

Low ESR/ESL |

Low equivalent series resistance and inductance contribute to better performance. |

|

Stability and Reliability |

Ceramic capacitors are known for their stability and reliability in various applications. |

|

Voltage Ratings |

Available in high voltage ratings, up to 200 V, suitable for diverse applications. |

|

Preferred Type |

X7R-type capacitors are preferred for their minimal capacitance change under DC bias. |

Ceramic capacitors, such as Murata’s GRM series and Samsung’s CL series, are widely used in consumer electronics, automotive systems, and telecommunications equipment. Their ability to filter high-frequency noise ensures smoother operation and improved circuit stability.

Electrolytic Capacitors for Energy Storage and Voltage Smoothing

Electrolytic capacitors are indispensable for energy storage and voltage smoothing in circuit design. These capacitors use an electrolyte to achieve high capacitance values, making them ideal for applications requiring bulk filtering and stable power delivery.

Note: Aluminum electrolytic capacitors are commonly used in power supply circuits to filter and stabilize voltage.

The energy storage efficiency of traditional aluminum electrolytic capacitors reaches 80%, making them reliable for circuits requiring temporary energy reservoirs. High energy density materials further enhance their performance by reducing fluctuations and increasing reliability. Engineers often pair these capacitors with smoothing algorithms, such as moving averages, to minimize voltage ripple and ensure consistent operation.

-

The energy storage efficiency of traditional aluminum electrolytic capacitors is 80%.

-

High energy storage density materials exhibit less fluctuation, ensuring higher reliability.

-

Smoothing algorithms, such as moving averages, reduce data fluctuations for effective voltage smoothing.

Electrolytic capacitors, such as Panasonic’s EEU-FR series and Nichicon’s UHE series, are widely used in automotive electronics, industrial machinery, and audio equipment. Their ability to store and release energy rapidly makes them essential for circuits requiring stable voltage and reliable performance.

Film Capacitors for Precision in Signal Processing

Film capacitors are celebrated for their precision and stability in signal processing applications. These capacitors use thin plastic films as the dielectric material, providing high insulation resistance and low energy loss. Their consistent performance over time makes them ideal for circuits requiring accuracy and reliability.

Film capacitors are commonly used in audio systems, power filtering, and EMI suppression. For example, WIMA’s MKP series and Panasonic’s ECW series are popular choices for industrial and automotive applications. These capacitors also excel in AC circuits, where their low ESR and high voltage ratings ensure efficient operation.

Tip: Engineers often select film capacitors for applications requiring high stability and minimal signal distortion.

|

Feature |

Benefit |

|---|---|

|

High Insulation Resistance |

Ensures minimal energy loss and consistent performance. |

|

Low ESR |

Reduces signal distortion and enhances efficiency. |

|

Wide Voltage Range |

Suitable for diverse applications, including industrial and automotive systems. |

|

Stability Over Time |

Maintains reliable performance in long-term applications. |

Film capacitors, such as Kemet’s R82 series and Panasonic’s ECQ series, are preferred for their ability to handle high voltages and suppress electromagnetic interference. Their precision and stability make them indispensable in circuits requiring accurate signal processing and reliable operation.

Tantalum Capacitors for Space-Constrained Applications

Tantalum capacitors are indispensable in modern electronics, especially in applications where space is at a premium. Their compact size, high capacitance, and exceptional reliability make them a preferred choice for devices like smartphones, medical equipment, and automotive electronics. These capacitors excel in environments requiring stable performance under extreme conditions, such as high temperatures or radiation exposure.

Note: Tantalum capacitors are often used in critical systems where failure is not an option, such as aerospace and military applications.

Reliability tests and benchmarks highlight their suitability for demanding environments. For instance, MIL-STD-704/DO-160 ensures uninterrupted power during brief interruptions, making these capacitors ideal for military and commercial aircraft. NASA EEE-INST-002 qualifies them for use in satellites and spacecraft, where repair is impossible. Additionally, the Mars Organic Molecule Analyzer (MOMA) demonstrates their ability to function as critical power reservoirs in extreme conditions.

|

Test/Benchmark |

Description |

|---|---|

|

MIL-STD-704/DO-160 |

Ensures uninterrupted power during brief interruptions, suitable for military and commercial aircraft. |

|

NASA EEE-INST-002 |

Qualified for deployment on satellites and spacecraft, ensuring mission-critical reliability. |

|

Mars Organic Molecule Analyzer (MOMA) |

Functions as a critical power reservoir in extreme environments, requiring ultra-reliable performance. |

These capacitors also feature radiation-hardened construction and extreme temperature tolerance, making them suitable for space-constrained and high-stress applications. Engineers often select tantalum capacitors for their long lifespan and efficient power storage, ensuring consistent performance in critical systems.

-

High capacitance and small size

-

Long lifespan and efficient power storage

-

Stable performance in extreme conditions

-

Radiation-hardened construction

-

Extreme temperature tolerance

Conductive Polymer Capacitors for Automotive and Industrial Applications

Conductive polymer capacitors are a modern innovation designed to meet the rigorous demands of automotive and industrial applications. These capacitors use a conductive polymer as the electrolyte, which significantly reduces equivalent series resistance (ESR). This property enhances their performance in high-frequency circuits and allows them to handle higher ripple currents compared to traditional tantalum capacitors.

Tip: Conductive polymer capacitors are ideal for applications requiring high reliability and efficiency, such as motor drives, power supplies, and telecommunications equipment.

Performance data underscores their advantages over traditional tantalum capacitors. For example, conductive polymer capacitors exhibit significantly lower ESR, enabling efficient power delivery with minimal energy loss. They also support ripple currents up to eight times higher, making them suitable for high-frequency and high-power applications.

|

Performance Metric |

Conductive Polymer Capacitors |

Traditional Tantalum Capacitors |

|---|---|---|

|

Equivalent Series Resistance (ESR) |

Significantly lower |

Higher |

|

Ripple Current |

Eight times higher |

Lower |

|

Capacitance Retention at High Frequencies |

Improved |

Standard |

|

Energy Density (Joules/cc) |

Higher |

Lower |

|

Voltage Range |

2.5V to 125V |

Limited |

|

Voltage Derating |

90% with 10% for up to 10V |

Standard derating |

|

Failure Mode |

Benign |

Potentially catastrophic |

These capacitors also offer improved capacitance retention at high frequencies and a broader voltage range, from 2.5V to 125V. Their benign failure mode ensures safer operation, even under demanding conditions. Engineers frequently use conductive polymer capacitors in automotive electronics, such as electric vehicle powertrains, and in industrial control systems, where consistent performance is critical.

Choosing the Right Capacitor for Your Design Needs

Selecting the optimal capacitor for a specific circuit design requires careful consideration of several criteria. Engineers must evaluate factors such as capacitance value, voltage rating, and tolerance to ensure compatibility with the application. Each criterion plays a vital role in determining the capacitor’s performance and reliability.

|

Criteria |

Description |

|---|---|

|

Capacitance Value |

Determines the energy storage capacity and impedance at a specific frequency. |

|

Voltage Rating |

Must exceed the expected voltage in the circuit for safe operation. |

|

Tolerance |

Indicates permissible deviation from nominal capacitance; important for precision applications. |

|

Temperature Coefficient |

Reflects how capacitance changes with temperature variations. |

|

Dielectric Material |

Affects performance characteristics, cost, and application suitability. |

|

Equivalent Series Resistance |

Influences power dissipation and efficiency, especially at higher frequencies. |

|

Equivalent Series Inductance |

Significant at higher frequencies, impacting overall capacitor performance. |

For high-frequency noise filtering, ceramic capacitors are often the best choice due to their low ESR and compact size. In contrast, electrolytic capacitors excel in energy storage and voltage smoothing applications. Film capacitors provide unmatched stability and precision, making them ideal for signal processing. Tantalum capacitors are perfect for space-constrained designs, while conductive polymer capacitors offer superior performance in high-frequency and high-reliability environments.

Tip: Engineers should always consider the operating environment, including temperature and voltage conditions, when selecting a capacitor.

By understanding the unique properties of each capacitor type, designers can optimize circuit performance and ensure long-term reliability. Proper selection not only enhances efficiency but also minimizes the risk of component failure, making it a critical step in the design process.

Capacitors play a pivotal role in solving circuit design challenges by ensuring stability, reliability, and efficiency. Their unique properties, such as dielectric materials and frequency response, make them indispensable for applications like noise filtering, energy storage, and voltage regulation. Selecting the right capacitor type is crucial for maintaining signal integrity and achieving optimal performance in electronic circuits.

Comparative Performance of Capacitor Types:

|

Capacitor Type |

Dielectric Material |

Dissipation Factor |

Insulation Resistance |

Frequency Response |

|---|---|---|---|---|

|

Ceramic Capacitors |

Ceramic |

Low |

High |

Excellent |

|

Electrolytic Capacitors |

Electrolyte |

Moderate |

Moderate |

Good |

|

Film Capacitors |

Plastic Film |

Very Low |

Very High |

Excellent |

|

Tantalum Capacitors |

Tantalum |

Low |

High |

Good |

|

Conductive Polymer Capacitors |

Polymer |

Very Low |

High |

Excellent |

-

Capacitors are essential for filtering, energy processing, and signal transfer in circuits.

-

Different dielectric materials influence performance, with some better suited for specific applications like audio or high-frequency systems.

-

Choosing the right capacitor ensures signal integrity and long-term reliability.

What is the primary purpose of a capacitor in a circuit?

Capacitors store and release electrical energy to stabilize voltage, filter noise, and manage power flow. They ensure smooth operation by compensating for fluctuations in electrical signals. Their role is critical in maintaining circuit efficiency and reliability.

How do engineers choose the right capacitor for a design?

Engineers consider factors like capacitance value, voltage rating, and temperature tolerance. They also evaluate the application’s requirements, such as noise filtering or energy storage. Selecting the correct type ensures optimal performance and long-term reliability.

Why are ceramic capacitors preferred for high-frequency applications?

Ceramic capacitors offer low equivalent series resistance (ESR) and high resonant frequencies. These properties make them ideal for filtering high-frequency noise and stabilizing voltage in compact, high-speed circuits like smartphones and telecommunications equipment.

Can capacitors improve energy efficiency in circuits?

Yes, capacitors enhance energy efficiency by reducing power losses and stabilizing voltage. They store energy during low-demand periods and release it during peak demand, ensuring consistent power delivery and minimizing waste.

What makes tantalum capacitors suitable for space-constrained designs?

Tantalum capacitors provide high capacitance in a compact size. Their robust construction ensures reliability under extreme conditions, making them ideal for applications like medical devices, aerospace systems, and smartphones where space is limited.

See Also

Understanding MC9S12DJ256MFUE Specs for Automotive Use

M30280FAHP: A Dependable Option for Medical ICs

Reasons to Select Coilcraft XPL2010 for VRM/VRD

Unveiling Key Automotive Features of FREESCALE MCF5251CVM140

Three Essential Features of SPC5605BMLL6 and SPC5607BMLL6 ECUs