Vishay’s TMBS® rectifiers bring transformative advancements to modern electronics. Their innovative design leverages Trench MOS Barrier Schottky technology to maximize energy efficiency while minimizing thermal challenges. Compact packaging, such as the DFN33A, reduces size by up to 44% compared to standard SMB packages, enabling efficient use of PCB space.

These rectifiers excel in high-frequency applications. Vishay’s showcase at PCIM Europe 2022 demonstrated their focus on automotive-grade solutions with AEC-Q101 qualified 60 V, 100 V, and 150 V TMBS rectifiers. These products improve power density and thermal management, ensuring reliable performance even in demanding environments.

Key Takeaways

-

TMBS® rectifiers use less energy with low voltage drops. They work well in high-speed electronics.

-

The small DFN33A design saves 44% of PCB space. This helps make smaller and better devices.

-

These rectifiers work safely in heat up to +175°C. They perform well even in tough conditions.

-

TMBS® rectifiers meet AEC-Q101 standards, so they are great for cars like EV chargers and engines.

-

They last long, waste less power, save money, and help the environment in electronics production.

Features of TMBS® Rectifiers

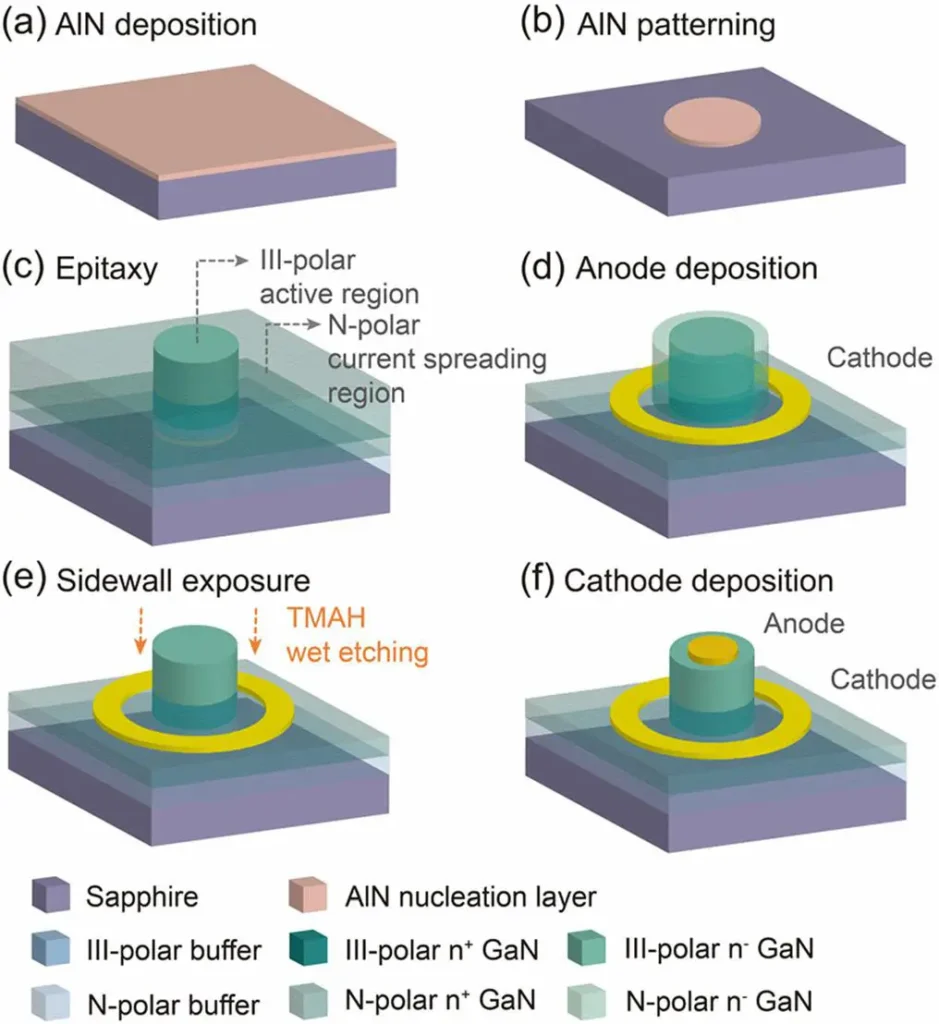

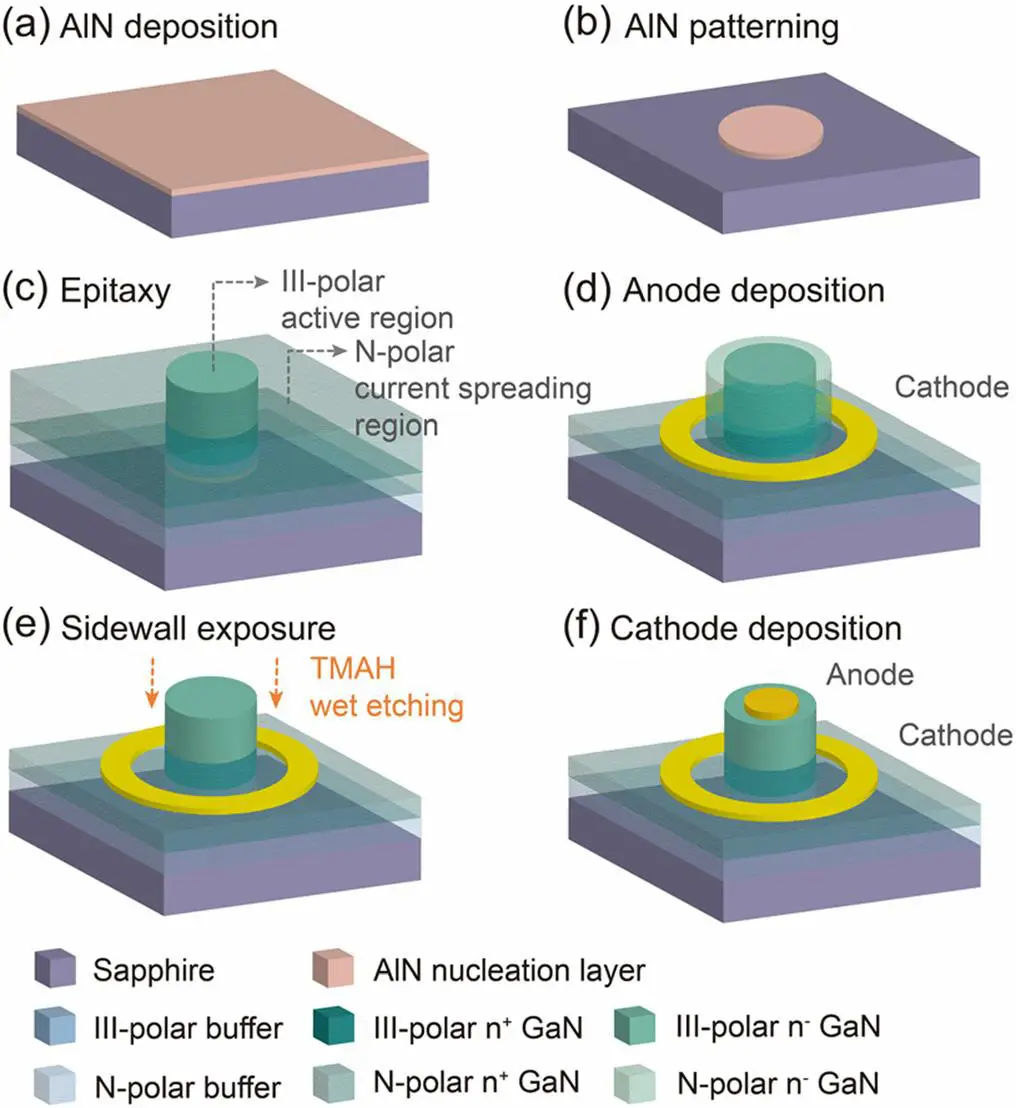

Trench MOS Barrier Schottky Technology

Trench MOS Barrier Schottky rectifiers represent a significant leap in semiconductor technology. Their advanced trench structure enhances electric field control, enabling superior static and dynamic electrical performance. This design reduces forward voltage drop and leakage current while maintaining high breakdown voltage, making them ideal for high-efficiency and high-voltage applications.

Unlike conventional planar Schottky rectifiers, these devices excel in thermal management and energy efficiency. They operate reliably at temperatures up to +175°C, ensuring consistent performance in demanding environments. The trench structure also supports a wide range of voltage ratings, from 60 V to 600 V, catering to diverse application needs.

TMBS® rectifiers’ innovative design not only improves energy efficiency but also extends the lifespan of electronic systems by minimizing thermal stress.

Compact DFN33A Package Design

The DFN33A package design sets a new standard for space-saving solutions in modern electronics. With a footprint of just 3.3 mm x 3.3 mm and a profile thickness of 0.88 mm, this package is 44% smaller than traditional SMB packages and 20% smaller than SMPA packages. This compact design optimizes PCB space, enabling engineers to create smaller, more efficient devices.

|

Feature |

DFN33A Package |

SMB (DO-214AA) |

SMPA (DO-220AA) |

|---|---|---|---|

|

Footprint Size |

3.3 mm x 3.3 mm |

44% smaller |

20% smaller |

|

Profile Thickness |

0.88 mm |

2.6 times thicker |

7% thinner |

The DFN33A package also incorporates wettable flanks, which facilitate automatic optical inspection (AOI). This feature streamlines the manufacturing process by eliminating the need for X-ray inspections, reducing production time and costs.

High Current Ratings and Voltage Options

TMBS® rectifiers offer high current ratings and versatile voltage options, making them adaptable to a wide range of modern circuits. These surface-mount TMBS devices include 16 new 2A and 3A models, with forward voltage drops as low as 0.36V for 2A devices and 0.37V for 3A devices. Voltage options range from 45 V to 200 V, ensuring compatibility with various applications.

Additionally, these rectifiers are designed to handle high temperatures, with a maximum operating junction temperature of +175°C. Their RoHS-compliant and halogen-free construction aligns with environmental standards, while AEC-Q101 qualified versions ensure reliability in automotive applications.

The combination of high current ratings, diverse voltage options, and robust thermal performance makes TMBS® rectifiers a versatile choice for modern electronic systems.

Superior Thermal Performance and Reliability

TMBS® rectifiers from Vishay demonstrate exceptional thermal performance, making them a reliable choice for modern electronics. Their advanced design ensures efficient heat dissipation, even in high-temperature environments. These rectifiers can operate at junction temperatures of up to +175°C, which allows them to maintain consistent functionality under demanding conditions. This capability reduces the risk of overheating, ensuring the longevity of electronic systems.

The DFN33A package further enhances reliability by incorporating features that support thermal management. Its compact design minimizes thermal resistance, enabling better heat transfer from the rectifier to the surrounding environment. This design not only improves efficiency but also reduces the need for additional cooling components, which simplifies system design.

Vishay’s TMBS® rectifiers also feature low forward voltage drops and minimal leakage currents. These characteristics contribute to reduced power loss, which helps maintain stable operation over extended periods. Engineers can rely on these rectifiers to deliver consistent performance, even in applications requiring high power density.

The combination of superior thermal performance and robust reliability makes TMBS® rectifiers an ideal solution for applications in automotive, industrial, and consumer electronics.

Benefits of TMBS® Rectifiers

High Power Density for Space-Saving Designs

TMBS® rectifiers provide higher power density, making them ideal for compact electronic designs. Their innovative DFN33A package reduces the footprint by 44% compared to traditional SMB packages. This compact size allows engineers to optimize PCB layouts, enabling the development of smaller and more efficient devices.

The reduced size does not compromise performance. These rectifiers handle high current ratings, reaching up to 9 A, while maintaining reliable operation. This combination of compact design and robust performance supports the growing demand for space-saving, high-efficiency solutions in modern electronics.

By offering higher power density, TMBS® rectifiers enable manufacturers to create advanced systems without sacrificing valuable PCB space.

Enhanced Energy Efficiency and Low Forward Voltage Drop

Energy efficiency is a critical factor in modern electronics. TMBS® rectifiers excel in this area by minimizing power loss. Their low forward voltage drop, as low as 0.36 V for 2 A models, reduces energy consumption and heat generation. This feature enhances the overall efficiency of electronic systems, particularly in high-frequency applications like DC/DC converters and inverters.

These rectifiers also exhibit minimal leakage current, further contributing to energy savings. Their ability to operate at temperatures up to +175°C ensures consistent performance, even in demanding environments. This makes them a reliable choice for applications requiring high-efficiency solutions.

TMBS® rectifiers’ energy-efficient design not only reduces operational costs but also supports sustainable practices in electronics manufacturing.

Compliance with Industry Standards and Environmental Regulations

Vishay’s TMBS® rectifiers meet stringent industry standards, ensuring reliability and safety. Automotive-grade versions, such as the AEC-Q101 qualified models, demonstrate their suitability for demanding applications like EV chargers and powertrains. These rectifiers also comply with RoHS and halogen-free regulations, reflecting Vishay’s commitment to environmental responsibility.

The DFN33A package incorporates features like wettable flanks, which facilitate automatic optical inspection (AOI). This streamlines the manufacturing process, ensuring consistent quality while reducing production costs. Additionally, the rectifiers’ MSL moisture sensitivity level of 1 guarantees durability and long-term performance.

By adhering to industry standards and environmental regulations, TMBS® rectifiers provide manufacturers with a dependable and eco-friendly solution for modern electronics.

Durability and Long-Term Cost-Effectiveness

Vishay’s TMBS® rectifiers stand out for their exceptional durability and cost-effectiveness, making them a reliable choice for modern electronic systems. These rectifiers are designed to withstand challenging operating conditions, ensuring long-term performance and reduced maintenance costs.

Built to Last in Demanding Environments

TMBS® rectifiers feature robust construction that supports high-temperature operations up to +175°C. This capability allows them to perform consistently in harsh environments, such as automotive powertrains or industrial motor drives. Their RoHS-compliant and halogen-free design further enhances their reliability by meeting stringent environmental and safety standards.

Tip: High-temperature tolerance reduces the risk of component failure, ensuring uninterrupted operation in critical applications.

Reduced Maintenance and Replacement Costs

The advanced trench structure of TMBS® rectifiers minimizes power loss and thermal stress. This design not only improves energy efficiency but also extends the lifespan of the components. By reducing the need for frequent replacements, these rectifiers help manufacturers lower long-term operational costs.

-

Key Features Contributing to Cost-Effectiveness:

-

Low forward voltage drop, reducing energy consumption.

-

Minimal leakage current, enhancing system stability.

-

Automotive-grade versions (AEC-Q101 qualified) for high-reliability applications.

-

Supporting Sustainable Practices

Durability also plays a crucial role in promoting sustainability. TMBS® rectifiers’ long service life reduces electronic waste, aligning with global efforts to minimize environmental impact. Their compliance with industry standards ensures that manufacturers can integrate them into eco-friendly designs without compromising performance.

Note: Choosing durable components like TMBS® rectifiers not only saves costs but also supports environmentally responsible manufacturing.

A Smart Investment for the Future

Investing in TMBS® rectifiers offers both immediate and long-term benefits. Their ability to handle high currents and voltages while maintaining reliability makes them suitable for a wide range of applications. By combining durability with cost-effectiveness, these rectifiers provide a smart solution for engineers seeking to optimize performance and reduce expenses.

TMBS® rectifiers deliver a winning combination of durability, efficiency, and cost savings, making them an essential component in modern electronics.

Applications of TMBS® Rectifiers

Automotive Electronics: EV Chargers and Powertrains

TMBS® rectifiers play a pivotal role in automotive electronics, particularly in EV chargers and powertrains. Their high current ratings and low forward voltage drop enhance energy efficiency, which is critical for electric vehicles. Automotive-grade versions, such as AEC-Q101 qualified rectifiers, ensure reliability in demanding environments. These rectifiers support high-frequency inverters and DC/DC converters, enabling faster charging and improved power management.

The automotive diode segment has experienced significant growth due to the adoption of energy-efficient solutions. In 2022, the segment grew by 16%, driven by advancements in EV technology. TMBS® rectifiers contribute to this growth by offering superior thermal performance and durability, which are essential for high-temperature operations in powertrain systems.

|

Year |

Growth Rate |

Application Area |

|---|---|---|

|

2022 |

16% |

Diode segment in automotive electronics |

TMBS® rectifiers’ compact design and robust performance make them indispensable for modern automotive applications.

Industrial Systems: Power Supplies and Motor Drives

Industrial systems demand reliable components for power supplies and motor drives. TMBS® rectifiers meet these requirements with their high current capabilities and versatile voltage options. Their ability to operate at temperatures up to +175°C ensures consistent performance in harsh industrial environments. These rectifiers reduce power loss, which improves the efficiency of telecom power supply applications and other industrial systems.

The DFN33A package design optimizes PCB space, allowing engineers to create compact and efficient power supply units. TMBS® rectifiers also minimize thermal resistance, which simplifies cooling system designs. This feature is particularly beneficial for motor drives, where heat management is crucial for maintaining operational stability.

TMBS® rectifiers provide a reliable solution for industrial systems, supporting energy-efficient designs and reducing long-term operational costs.

Consumer Electronics: Smartphones and Wearables

TMBS® rectifiers enhance the performance of consumer electronics, including smartphones and wearables. Their ultra-low forward voltage drop is essential for fast-charging applications, while their high surge current capability ensures efficient power management. These features align with the growing demand for energy-efficient solutions in consumer devices.

Market research highlights a 16% year-on-year growth in the diode segment for consumer electronics in 2022. This growth is driven by the expansion of 5G infrastructure and the need for compact, high-performance components. TMBS® rectifiers address these requirements with their space-saving DFN33A package and robust thermal performance.

|

Performance Metric |

Value |

|---|---|

|

Ultra-low forward voltage |

Essential for fast-charging |

|

High surge current capability |

Critical for efficient power management |

|

Year-on-Year growth in diode segment |

|

|

Driving factors |

Rising 5G infrastructure and energy-efficient solutions |

TMBS® rectifiers enable manufacturers to create advanced consumer devices that meet the demands of modern technology.

Renewable Energy: Solar Inverters and Battery Storage

Renewable energy systems demand components that deliver efficiency and reliability. TMBS® rectifiers excel in solar inverters and battery storage applications, where energy conversion and management are critical. Their advanced design ensures optimal performance in high-frequency circuits, making them a preferred choice for modern renewable energy solutions.

Key Benefits for Solar Inverters

Solar inverters convert DC power from solar panels into AC power for household or grid use. TMBS® rectifiers enhance this process by reducing power loss during conversion. Their low forward voltage drop minimizes energy waste, ensuring maximum power output. High current ratings, reaching up to 9 A, support the demands of large-scale solar installations.

Tip: TMBS® rectifiers’ ability to operate at temperatures up to +175°C ensures consistent performance in outdoor environments exposed to heat and sunlight.

Supporting Battery Storage Systems

Battery storage systems require efficient charging and discharging mechanisms. TMBS® rectifiers facilitate these processes with minimal leakage current and superior thermal management. Their compact DFN33A package design optimizes PCB space, allowing manufacturers to create smaller, more efficient battery modules.

|

Feature |

Benefit for Battery Storage Systems |

|---|---|

|

Low forward voltage drop |

Reduces energy loss during charging |

|

Minimal leakage current |

Enhances battery efficiency |

|

Compact package design |

Saves space in battery modules |

Promoting Sustainability

TMBS® rectifiers align with the goals of renewable energy by supporting sustainable practices. Their RoHS-compliant and halogen-free construction reduces environmental impact. Long-term durability minimizes electronic waste, contributing to eco-friendly energy solutions.

TMBS® rectifiers empower engineers to design renewable energy systems that are efficient, reliable, and environmentally responsible.

Addressing Challenges in Modern Electronics

Overcoming Thermal Management Issues

Thermal management remains a critical challenge in modern electronics. Vishay’s TMBS® rectifiers address this issue with their advanced design. These rectifiers operate efficiently at temperatures up to +175°C, ensuring consistent performance in high-temperature environments. Their low forward voltage drop minimizes heat generation, reducing the risk of overheating.

The DFN33A package further enhances thermal management. Its compact design lowers thermal resistance, allowing heat to dissipate more effectively. This feature eliminates the need for bulky cooling systems, simplifying device designs. Engineers can rely on TMBS® rectifiers to maintain stable operation, even in applications requiring high power density.

Efficient thermal management improves system reliability and extends the lifespan of electronic components.

Enabling Miniaturization with High Power Density

Modern electronics demand smaller, more efficient designs. TMBS® rectifiers enable miniaturization by combining compact packaging with high power density. The DFN33A package reduces the footprint by 44% compared to traditional SMB packages. This space-saving design allows manufacturers to optimize PCB layouts, creating smaller devices without sacrificing performance.

These rectifiers handle high current ratings, reaching up to 9 A, while maintaining reliable operation. Their ability to deliver high power density supports the development of compact systems for automotive, industrial, and consumer applications. Engineers can integrate TMBS® rectifiers into designs that prioritize efficiency and space conservation.

Miniaturization with high power density drives innovation in modern electronics, enabling advanced systems in smaller form factors.

Supporting High-Performance and Reliable Systems

High-performance systems require components that deliver consistent reliability. TMBS® rectifiers meet this demand with their robust construction and advanced features. Their low forward voltage drop reduces power loss, ensuring efficient energy conversion. Minimal leakage current enhances system stability, supporting reliable operation over extended periods.

Automotive-grade versions, such as AEC-Q101 qualified rectifiers, demonstrate their suitability for demanding applications. These rectifiers perform reliably in harsh environments, including automotive powertrains and industrial motor drives. Their compliance with industry standards ensures safety and durability, making them a dependable choice for high-performance systems.

TMBS® rectifiers empower engineers to design systems that combine efficiency, reliability, and long-term durability.

Availability and Support for TMBS® Rectifiers

Product Availability and Lead Times

Vishay offers a wide range of TMBS® rectifiers, including models like SE40N3D, SE60N3G, and V5N3103. These products are readily available for various applications, from automotive to renewable energy systems. Engineers can choose from 27 standard and Trench MOS Barrier Schottky rectifiers, ensuring compatibility with diverse design requirements.

The lead time for these rectifiers is approximately eight weeks. This timeline reflects Vishay’s commitment to delivering high-quality components promptly. The company ensures that production quantities meet the demands of both small-scale and large-scale projects.

Note: Vishay’s efficient supply chain management minimizes delays, helping manufacturers stay on schedule.

Sample Options for Prototyping and Testing

Vishay provides sample options for engineers who need to prototype and test their designs. These samples include popular models like SE40N3J, V5N3M103, and V7N3103. By offering these options, Vishay supports innovation and accelerates the development process.

Prototyping with TMBS® rectifiers allows engineers to evaluate performance under real-world conditions. They can test features like low forward voltage drop, high current ratings, and thermal reliability. This hands-on approach ensures that the final product meets design specifications.

Tip: Requesting samples early in the design phase can save time and reduce the risk of errors during production.

Global Distribution and Technical Assistance

Vishay’s TMBS® rectifiers are available through a global distribution network. This network ensures that customers worldwide can access products like V6N3103, V5N3L63, and V7N3L63. Distributors maintain stock levels to meet regional demands, providing a seamless purchasing experience.

In addition to distribution, Vishay offers technical assistance to support engineers. Experts provide guidance on selecting the right rectifier for specific applications. They also assist with troubleshooting and optimizing designs for maximum efficiency.

|

Support Services |

Details |

|---|---|

|

Product Selection Guidance |

Helps identify the best rectifier model |

|

Design Optimization |

Ensures efficient system performance |

|

Troubleshooting Assistance |

Resolves technical challenges |

Vishay’s global presence and expert support make it easier for engineers to integrate TMBS® rectifiers into their projects.

TMBS® rectifiers redefine efficiency and reliability in modern electronics. Their advanced features, such as Trench MOS Barrier Schottky technology and the compact DFN33A package, enhance energy efficiency and thermal performance. These rectifiers cater to diverse applications, from automotive systems to renewable energy solutions, showcasing their versatility across industries.

Engineers and manufacturers can explore the full potential of these rectifiers by accessing Vishay’s global distribution network. Requesting samples or technical support ensures seamless integration into innovative designs. TMBS® rectifiers empower the development of high-performance, sustainable electronic systems.

What is the primary advantage of TMBS® rectifiers?

TMBS® rectifiers offer superior energy efficiency due to their low forward voltage drop. This feature minimizes power loss, making them ideal for high-frequency applications. Their compact design also saves PCB space, enabling smaller and more efficient electronic devices.

Are TMBS® rectifiers suitable for automotive applications?

Yes, TMBS® rectifiers include AEC-Q101 qualified versions designed for automotive use. These rectifiers handle high temperatures and demanding conditions, making them reliable for EV chargers, powertrains, and other automotive systems.

How do TMBS® rectifiers improve thermal management?

TMBS® rectifiers operate efficiently at temperatures up to +175°C. Their advanced trench structure and compact DFN33A package enhance heat dissipation. These features reduce the risk of overheating and eliminate the need for bulky cooling systems.

Can TMBS® rectifiers support renewable energy systems?

TMBS® rectifiers are ideal for renewable energy applications like solar inverters and battery storage. Their low forward voltage drop reduces energy loss during power conversion. Additionally, their durability ensures consistent performance in outdoor environments exposed to heat and sunlight.

Where can engineers access TMBS® rectifiers?

Engineers can access TMBS® rectifiers through Vishay’s global distribution network. Samples are available for prototyping and testing. Technical assistance is also provided to help engineers select the right model and optimize their designs.

Tip: Requesting samples early ensures smooth integration into your project.

See Also

M30280FAHP: A Dependable Option for Medical Integrated Circuits

IRF820: A Versatile N-Channel MOSFET for Power Applications

Comparing STM32F401VCT6 And STR750FV2T6: Transforming Medical Devices

How Advancing Technology Continues To Enhance Electronic Excellence

Three Effective Methods For Integrating MC9S12XET512VAG