A pressure sensor measures the force exerted by gases or liquids and converts it into an electrical signal. Its working principle involves detecting changes in pressure and translating them into data that can be analyzed or used for control systems. These pressure sensors play a pivotal role in industries by ensuring safety, efficiency, and precision.

In modern technology, pressure sensors have become indispensable. Their applications range from monitoring tire pressure in vehicles to regulating airflow in medical devices. The global market for pressure sensor supply reflects their growing importance, with a projected value of $35.04 billion by 2033. Innovations such as AI integration and advancements in MEMS technology have further enhanced their functionality, making them smaller, faster, and more reliable.

Key Takeaways

-

Pressure sensors change physical pressure into electrical signals. This helps monitor systems accurately in many areas.

-

There are different types of pressure sensors, like absolute, gauge, and differential. Each type is used for specific jobs in industries like healthcare and cars.

-

Picking the right pressure sensor is important. It keeps systems working well and safe.

-

New technology, like MEMS and IoT, makes pressure sensors work better and last longer.

-

Knowing how pressure sensors, transducers, and transmitters are different helps you choose the right one for your needs.

Working Principle of a Pressure Sensor

How Pressure is Measured

Pressure sensors measure pressure by detecting the force exerted by a gas or liquid on a sensitive element. This force is typically expressed in units such as Pascals (Pa) or pounds per square inch (psi). The sensor’s design allows it to respond to changes in pressure, whether absolute, gauge, or differential. For instance, in a hydraulic system, the sensor measures the pressure difference between two points to ensure proper operation.

Different sensing mechanisms are used depending on the application. Resistive sensing measures changes in electrical resistance caused by pressure-induced deformation. Capacitive sensing detects variations in capacitance due to changes in the distance between two plates. Piezoelectric sensing relies on materials that generate an electrical charge when subjected to pressure. These methods enable accurate pressure measurement across diverse environments.

|

Sensing Mechanism |

Key Features |

Applications |

|---|---|---|

|

Resistive Sensing |

Measures resistance changes due to deformation. |

Flexible and stretchable applications. |

|

Capacitive Sensing |

High sensitivity to small pressure variations. |

Dynamic pressure measurements. |

|

Piezoelectric Sensing |

High sensitivity and linearity under pressure. |

Precise measurements in challenging conditions. |

Conversion of Pressure into Electrical Signals

The conversion of pressure into electrical signals is the core of a pressure sensor’s functionality. When a liquid or gas exerts force on the sensor’s diaphragm, the deformation triggers a response in the sensing element. This response is then converted into an electrical output, which can be processed and analyzed.

Several techniques facilitate this conversion:

-

Strain gauges measure physical deformations caused by pressure changes and convert them into voltage or electric signals.

-

A 4-20mA pressure transducer outputs a current proportional to the measured pressure, with specific current values corresponding to defined pressure ranges.

-

Capacitive sensors detect changes in capacitance, while piezoelectric sensors generate electrical charges directly from pressure-induced stress.

These methods ensure precise signal processing, allowing pressure sensors to provide real-time data. For example, sensors with high-frequency signal outputs can capture rapid pressure fluctuations, making them ideal for dynamic applications like engine analysis.

Key Components of a Pressure Sensor

A pressure sensor consists of several key components that work together to measure pressure and produce an electrical signal:

-

Sensing Element: The core component that detects pressure changes. Common materials include silicon, ceramics, and piezoelectric crystals.

-

Diaphragm: A thin, flexible membrane that deforms under pressure. This deformation is critical for transferring force to the sensing element.

-

Signal Conditioning Circuit: Processes the raw electrical signal from the sensing element. It amplifies, filters, and converts the signal into a usable format.

-

Housing: Protects the internal components from environmental factors like moisture, dust, and extreme temperatures.

-

Electrical Connections: Transmit the processed signal to external systems for monitoring or control.

Testing confirms the reliability of these components. For instance, nanocomposite elements exhibit stable behavior over 500 strain cycles, ensuring durability. Additionally, electrical resistance tests show a linear response, indicating consistent performance under mechanical strain.

Types of Pressure Sensors

Pressure sensors come in various forms, each designed to meet specific application needs. Understanding the differences among these types is essential for selecting the right sensor for a given task. Below are three primary types of pressure sensors: absolute, gauge, and differential.

Absolute Pressure Sensors

Absolute pressure sensors measure pressure relative to a perfect vacuum. These sensors use a sealed reference chamber that contains no air or gas. This design ensures that the sensor provides accurate readings regardless of changes in atmospheric pressure. For example, they are commonly used in applications like barometric pressure monitoring and altitude measurement.

One of the key advantages of absolute pressure sensors is their high accuracy. They are not influenced by environmental factors such as weather or altitude, making them ideal for precision tasks. According to comparative studies, absolute pressure sensors offer an accuracy range of ±0.05% FS to ±0.01% FS, outperforming other types in precision-critical applications.

|

Sensor Type |

Accuracy Range |

Features |

|---|---|---|

|

Absolute Pressure Sensors |

±0.05% FS to ±0.01% FS |

Higher accuracy, not affected by atmospheric pressure, suitable for precision |

These sensors are widely used in industries like aerospace, where they monitor cabin pressure and ensure passenger safety. They also play a crucial role in weather stations for barometric pressure measurement.

Gauge Pressure Sensors

Gauge pressure sensors measure pressure relative to the surrounding atmospheric pressure. Unlike absolute sensors, they do not rely on a vacuum reference. Instead, they use the ambient air pressure as a baseline. This makes them suitable for applications where the pressure difference between a system and its environment is critical.

Gauge pressure sensors are commonly found in everyday applications. For instance, they are used in tire pressure monitoring systems (TPMS) to ensure safe driving conditions. They also play a vital role in hydraulic systems, where they monitor fluid pressure to prevent equipment failure.

These sensors are known for their fast response times, making them ideal for routine monitoring. However, their accuracy can be affected by environmental changes. Comparative data shows that gauge pressure sensors typically offer an accuracy range of ±0.1% FS to ±0.02% FS.

|

Sensor Type |

Accuracy Range |

Features |

|---|---|---|

|

Gauge Pressure Sensors |

±0.1% FS to ±0.02% FS |

Fast response time, suitable for routine monitoring, affected by environment |

Differential Pressure Sensors

Differential pressure sensors measure the pressure difference between two points. This capability makes them essential for applications like flow measurement, filtration monitoring, and leak detection. These sensors are designed to provide accurate readings even in dynamic environments.

One of the primary uses of differential pressure sensors is in HVAC systems. They monitor air pressure across filters to detect clogs and ensure efficient operation. In industrial settings, they are used to measure pressure differences in pipelines, helping to maintain optimal flow rates.

Differential pressure sensors require a stable environment for accurate readings. Their accuracy typically ranges from ±0.1% FS to ±0.02% FS, similar to gauge pressure sensors. However, their ability to perform differential measurement sets them apart.

|

Sensor Type |

Accuracy Range |

Features |

|---|---|---|

|

Differential Pressure Sensors |

±0.1% FS to ±0.02% FS |

Suitable for flow and filtration, requires stable environment |

These sensors are indispensable in industries where precise pressure measurement is critical for safety and efficiency.

Sealed Pressure Sensors

Sealed pressure sensors measure pressure relative to a fixed reference point, typically a sealed chamber with a pre-determined pressure. Unlike absolute pressure sensors, which use a vacuum as a reference, sealed sensors rely on a specific pressure value within the chamber. This design ensures consistent readings, even in environments with fluctuating atmospheric conditions.

These sensors are ideal for applications requiring long-term stability and durability. For instance, they are commonly used in hydraulic systems, where they monitor fluid pressure to ensure safe operation. They also play a critical role in industrial automation, where precise pressure measurement is essential for maintaining efficiency.

Sealed pressure sensors are particularly effective in high-pressure environments. Their robust construction allows them to withstand extreme conditions, making them suitable for aerospace and automotive applications. For example, they are often used to monitor hydraulic pressure in aircraft landing gear systems or transmission systems in vehicles.

|

Feature |

Description |

|---|---|

|

Reference Pressure |

Fixed, sealed chamber with a pre-determined pressure. |

|

Key Applications |

Hydraulic systems, industrial automation, aerospace, and automotive industries. |

|

Advantages |

Long-term stability, durability, and resistance to environmental fluctuations. |

Tip: When selecting a sealed pressure sensor, consider the operating pressure range and environmental conditions to ensure optimal performance.

Specialized Types of Pressure Sensors

Piezoresistive Pressure Sensors

A piezoresistive pressure sensor operates by detecting changes in electrical resistance caused by pressure-induced deformation. These sensors use materials like silicon, which exhibit a change in resistivity when subjected to mechanical stress. The deformation alters the resistance, which is then converted into an electrical signal.

Piezoresistive sensors are widely used due to their high sensitivity and accuracy. They are ideal for applications requiring precise measurements, such as medical devices and automotive systems. For instance, they are commonly found in blood pressure monitors and manifold absolute pressure sensors in engines.

|

Advantages |

Applications |

|---|---|

|

High sensitivity and accuracy |

Medical devices, automotive systems, and industrial process control. |

|

Compact design |

Suitable for integration into small devices like wearables and smartphones. |

Capacitive Pressure Sensors

A capacitive pressure sensor measures pressure by detecting changes in capacitance. It consists of two conductive plates separated by a dielectric material. When pressure is applied, the distance between the plates changes, altering the capacitance. This change is then converted into an electrical signal.

These sensors are known for their high sensitivity to small pressure variations. They are often used in dynamic applications, such as monitoring air pressure in HVAC systems or detecting differential measurement in filtration systems. Their ability to provide accurate readings in low-pressure environments makes them a popular choice for environmental monitoring.

|

Feature |

Description |

|---|---|

|

High sensitivity |

Detects small pressure variations with precision. |

|

Applications |

HVAC systems, environmental monitoring, and filtration systems. |

Optical Pressure Sensors

An optical pressure sensor uses light to measure pressure. It typically consists of a fiber optic cable and a sensing element. When pressure is applied, it causes a change in the light’s intensity, phase, or wavelength. This change is then analyzed to determine the pressure.

These sensors are highly resistant to electromagnetic interference, making them suitable for use in harsh environments. They are commonly used in aerospace and defense applications, where reliability and precision are critical. For example, they are often employed in altitude measurement systems and fuel monitoring.

|

Advantages |

Applications |

|---|---|

|

Immune to electromagnetic interference |

Aerospace, defense, and industrial automation. |

|

High precision |

Suitable for critical applications like altitude and fuel monitoring. |

Piezoelectric Pressure Sensors

A piezoelectric pressure sensor generates an electrical charge when subjected to mechanical stress. It uses materials like quartz or ceramics, which exhibit piezoelectric properties. The generated charge is proportional to the applied pressure, allowing for accurate measurement.

These sensors are ideal for dynamic applications, such as monitoring rapid pressure changes in engines or detecting vibrations in industrial machinery. Their high resonant frequency makes them suitable for high-speed measurements, ensuring reliable performance in challenging conditions.

|

Feature |

Description |

|---|---|

|

High resonant frequency |

Suitable for high-speed and dynamic measurements. |

|

Applications |

Engine monitoring, vibration detection, and industrial machinery. |

Note: Piezoelectric sensors are not suitable for static pressure measurements, as they require dynamic pressure changes to generate a signal.

Pressure Sensor Applications

Pressure sensors play a vital role in various industries, enabling precise pressure monitoring and control. Their versatility makes them indispensable in critical applications, ranging from automotive systems to healthcare devices and industrial automation.

Automotive Industry

In the automotive sector, pressure sensors enhance safety, efficiency, and performance. They are integral to systems like airbag deployment, engine management, and tire pressure monitoring. For example, airbag systems rely on pressure sensors to detect rapid changes during a collision, ensuring timely deployment. Engine management systems use these sensors to optimize fuel injection and combustion, improving fuel efficiency and reducing emissions. Tire pressure monitoring systems (TPMS) maintain optimal tire pressure, enhancing safety and fuel economy.

|

Application |

Benefit |

|---|---|

|

Airbag Deployment |

Enables rapid deployment of airbags through digital crash signals. |

|

Engine Management |

Optimizes fuel injection and combustion, improving performance. |

|

Tire Pressure Monitoring Systems |

Maintains optimal tire pressure, enhancing safety and fuel economy. |

Pressure sensors also help manufacturers meet regulatory requirements and address consumer demand for fuel-efficient vehicles. Their ability to provide precise measurement and control makes them essential in modern automotive design.

Healthcare and Medical Devices

Pressure sensors are critical in healthcare, where precision and reliability are paramount. They are used in devices like blood pressure monitors, ventilators, and infusion pumps. For instance, ventilators rely on pressure sensors to regulate airflow and ensure patient safety. Infusion pumps use these sensors to maintain accurate fluid delivery, preventing complications.

Clinical studies validate the importance of pressure sensors in medical devices. One study highlights the development of an alarm algorithm using multimodal sensors to predict infusion failure in neonates, enhancing the safety of intravenous catheters. Another study emphasizes the need for rigorous validation of biosensor accuracy to ensure reliable performance in medical applications.

|

Study Title |

Findings |

|---|---|

|

A Scoping Review of Integrated Medical Devices and Clinical Decision Support in the Acute Care Setting |

Development of an alarm algorithm using nanotechnology multimodal sensors to predict impending infusion failure in neonates, enhancing safety of peripheral intravenous catheters. |

|

Validation and verification framework and data integration of biosensors and in vitro diagnostic devices |

Discusses the importance of verifying biosensor accuracy and the distinction between engineering assessments and clinical validation. |

Industrial Automation

In industrial automation, pressure sensors ensure precision and efficiency in automated processes. They monitor and control pressure in pneumatic and hydraulic systems, providing real-time data for immediate adjustments. This capability reduces the risk of failures and enhances safety.

Pressure sensors also integrate with IoT systems, enabling remote monitoring and predictive maintenance. This integration minimizes downtime and improves operational efficiency. For example, sensors provide accurate measurements of fluid levels and flow rates, allowing early detection of potential issues. By optimizing processes and reducing energy consumption, they contribute to safer and more efficient manufacturing environments.

-

Pressure sensors allow real-time adjustments in manufacturing processes, preventing product damage.

-

They facilitate automation by integrating with PLCs, reducing human error and maintaining consistency.

-

Automation through sensors enables businesses to scale operations efficiently without significantly increasing labor costs.

The reliability and accuracy of pressure sensors make them indispensable in industrial automation, where they support critical applications and enhance overall productivity.

Aerospace and Aviation

Pressure sensors play a critical role in ensuring the safety and efficiency of aerospace systems. These sensors monitor hydraulic systems in aircraft, particularly in landing gears and braking systems, to guarantee safe operations during crucial phases such as takeoff and landing. Their ability to provide precise and reliable measurements makes them indispensable in aviation.

Modern aircraft systems demand high-precision sensors due to their increasing complexity and stringent safety requirements. Advancements in sensor technology, including the development of micro-electromechanical systems (MEMS), have resulted in smaller, more accurate, and durable pressure sensors. These innovations enable sensors to withstand extreme conditions, such as high altitudes and temperature fluctuations, enhancing their reliability in applications like engine monitoring and environmental control systems.

-

Pressure sensors ensure the proper functioning of hydraulic systems in landing gears and brakes.

-

MEMS technology has improved sensor accuracy and reduced size, making them ideal for aerospace applications.

-

Innovations in materials science have produced sensors capable of enduring harsh environments.

The aerospace industry continues to drive the demand for high-performance pressure sensors. Their integration into critical systems ensures operational safety and efficiency, making them a cornerstone of modern aviation technology.

Consumer Electronics and Appliances

Pressure sensors have become integral to the growing market for consumer electronics and smart appliances. These sensors enable advanced features in devices like smartphones, wearables, and connected home systems. For instance, smartphones use pressure sensors for altitude detection, while wearables rely on them for health monitoring and environmental sensing.

The demand for smart devices has surged, driven by tech-savvy consumers seeking innovative products with enhanced connectivity. Smart home systems, such as automated HVAC controls and water management systems, also utilize pressure sensors to optimize performance and energy efficiency. This trend has contributed to the rapid growth of the electronic pressure sensor market, which is projected to reach $29,710 million by 2033.

-

Smartphones and wearables use pressure sensors for altitude and health monitoring.

-

Smart home systems rely on these sensors for efficient water and air management.

-

Rising consumer interest in connected devices drives the adoption of pressure sensors.

As technology advances, pressure sensors continue to enable smarter, more efficient devices. Their versatility and precision make them essential in shaping the future of consumer electronics and appliances.

Pressure Sensors vs. Similar Devices

Pressure Sensors vs. Pressure Transducers

Pressure sensors and pressure transducers share similarities but differ in functionality and application. A pressure sensor detects pressure changes and converts them into an electrical signal. In contrast, a pressure transducer takes this process further by conditioning the signal, often converting it into a standardized output like voltage or current. This additional step makes pressure transducers suitable for integration into control systems.

Key distinctions arise in their operational mechanisms. Pressure sensors rely on an elastic diaphragm to detect pressure changes, which alters the pulse waveform morphology. Comparative analyses reveal that pressure sensors exhibit unique spectral characteristics, such as significant peaks and harmonics, distinguishing them from other sensor types. However, both devices perform comparably in pulse rate variability (PRV) metrics, indicating similar reliability in specific measurements.

-

Pressure Sensors: Detect pressure changes and produce raw electrical signals.

-

Pressure Transducers: Convert raw signals into standardized outputs for system integration.

These differences make pressure transducers ideal for industrial automation, where precise signal conditioning is essential.

Pressure Sensors vs. Pressure Transmitters

Pressure sensors and pressure transmitters differ in complexity and application. While a pressure sensor measures pressure and generates an electrical signal, a pressure transmitter amplifies and transmits this signal over long distances. Transmitters often include advanced features like digital communication protocols, making them suitable for large-scale industrial systems.

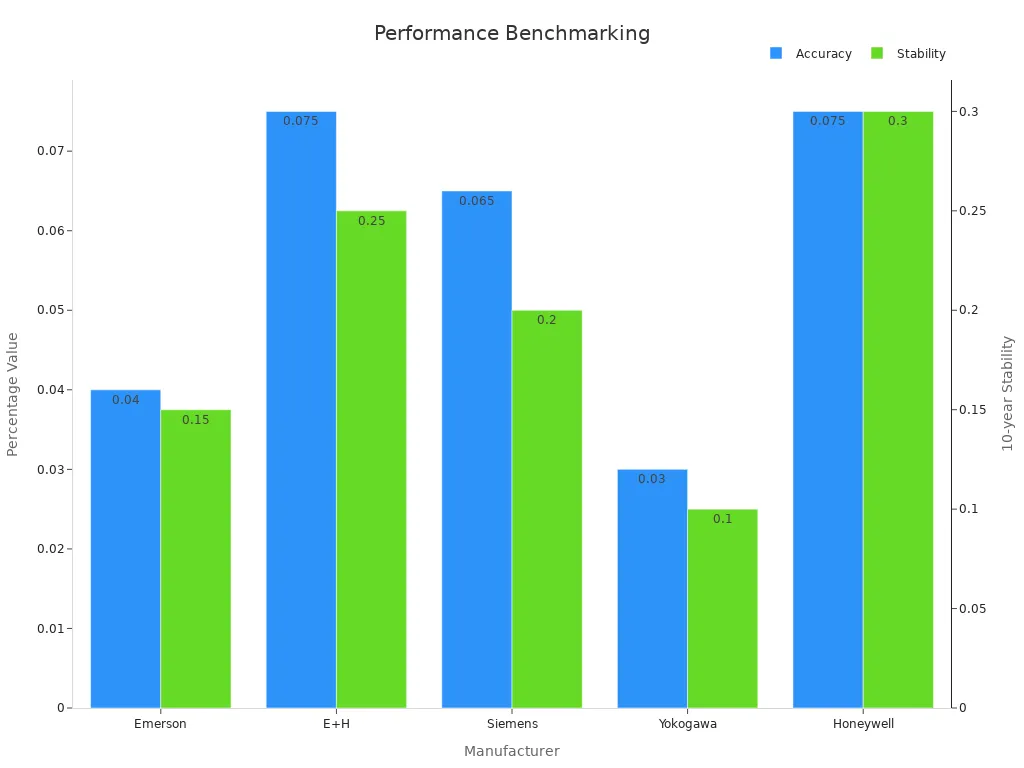

Benchmarking data highlights performance differences between these devices. For example, manufacturers like Yokogawa and Emerson produce pressure transmitters with high accuracy (up to 0.03% FS) and long-term stability (±0.1% over ten years). These features make transmitters ideal for applications requiring robust communication and media compatibility, such as hydrofluoric acid or high-viscosity fluids.

|

Manufacturer |

Accuracy (%FS) |

Stability (10-year) |

Communication |

Media Compatibility |

|---|---|---|---|---|

|

Emerson |

0.04 |

±0.15% |

HART/FF |

Hydrofluoric acid <48% |

|

Yokogawa |

0.03 |

±0.1% |

BRAIN |

High-viscosity fluids |

Transmitters excel in environments where signal integrity and durability are critical, while sensors are better suited for localized measurements.

Key Differences and Use Cases

Pressure sensors, transducers, and transmitters serve distinct purposes. Pressure sensors focus on detecting and measuring pressure changes. Transducers condition these signals for system integration, while transmitters ensure reliable communication over long distances. For instance, an oil pressure switch uses a diaphragm to activate a warning light when pressure drops, showcasing a simpler application. In contrast, chronically implanted pressure sensors handle complex challenges like biocompatibility and accurate transduction in medical environments.

|

Device Type |

Key Feature |

Example Use Case |

|---|---|---|

|

Pressure Sensor |

Measures pressure changes |

Blood pressure monitors |

|

Pressure Transducer |

Converts signals for system use |

Industrial process control |

|

Pressure Transmitter |

Amplifies and transmits signals |

Oil and gas pipeline monitoring |

These distinctions highlight the importance of selecting the right device for specific applications, ensuring optimal performance and reliability.

Pressure sensors operate by converting physical pressure into electrical signals, enabling precise monitoring and control across various applications. Their diverse types, including absolute, gauge, differential, and specialized sensors, cater to specific needs in industries like healthcare, automotive, and aerospace. Selecting the right pressure sensor ensures optimal performance and safety in these critical systems.

Advancements in pressure sensor technology continue to shape their future. Miniaturization and MEMS technology enable compact designs for smaller devices. Integration with IoT enhances real-time data monitoring in smart manufacturing. Flexible sensors open new possibilities in wearables and robotics, while digital outputs improve accuracy and reliability. These innovations highlight the growing role of pressure sensors in sustainability, healthcare, and automation.

What is the difference between absolute and gauge pressure sensors?

Absolute pressure sensors measure pressure relative to a vacuum, while gauge pressure sensors measure pressure relative to atmospheric pressure. Absolute sensors are ideal for precision tasks like barometric measurements. Gauge sensors are better for applications like tire pressure monitoring, where the difference from ambient pressure is critical.

How do piezoresistive pressure sensors work?

Piezoresistive pressure sensors detect changes in electrical resistance caused by mechanical stress. When pressure deforms the sensor’s material, the resistance changes. This change is converted into an electrical signal, enabling accurate pressure measurement. These sensors are widely used in medical devices and automotive systems.

Can pressure sensors measure both gases and liquids?

Yes, pressure sensors can measure both gases and liquids. Their design allows them to detect force exerted by any fluid medium. Applications include monitoring hydraulic systems, measuring air pressure in HVAC systems, and detecting gas pressure in industrial processes.

What factors should be considered when selecting a pressure sensor?

Key factors include the type of pressure (absolute, gauge, or differential), operating pressure range, environmental conditions, and required accuracy. For example, sealed pressure sensors are ideal for high-pressure environments, while capacitive sensors excel in detecting small pressure variations.

Are pressure sensors compatible with IoT systems?

Many modern pressure sensors integrate with IoT systems. They provide real-time data for remote monitoring and predictive maintenance. For instance, IoT-enabled sensors in industrial automation optimize processes by detecting pressure changes and sending alerts for immediate action.

Tip: Look for sensors with digital outputs and communication protocols like IoT compatibility for smart applications.

See Also

Utilizing ADXL357BEZ For Motion Sensors And Stabilization

Simple Guide For Integrating SN74LVC4245APW Sensors

ARTESYN NPT42-M: Enabling Power For Industrial Automation

Complete Overview Of AD1940YSTZ And AD1941YST Automotive DSPs

Understanding MC9S12DJ256MFUE Specs For Automotive Use