TPDxE05U06 TVS diodes are essential components that safeguard electronic circuits by protecting sensitive components against electrostatic discharge, or ESD. These diodes act as a barrier, preventing voltage spikes from damaging critical parts of consumer devices.

ESD protection is crucial in modern electronics like smartphones, laptops, and wearable gadgets. Static discharge can harm internal circuits, reducing device reliability. TPDxE05U06 diodes offer precise and efficient protection, ensuring longer device lifespans and enhanced performance.

By integrating TPDxE05U06 TVS diodes, engineers can achieve superior ESD immunity without compromising system performance, particularly in high-speed applications.

Key Takeaways

-

TPDxE05U06 TVS diodes keep electronics safe from static electricity. This helps devices last longer and work better.

-

Place the diodes close to spots where static might enter, like connectors. This makes them stop voltage spikes more effectively.

-

Diodes with very low capacitance (about 0.5 pF) avoid signal problems. They are great for fast-working devices.

-

Test ESD protection circuits carefully to check how well they work. Make sure they follow industry rules.

-

Adding TPDxE05U06 diodes makes electronics stronger. They are perfect for modern gadgets like phones and laptops.

Understanding ESD and the Need for Protection

What is ESD and how does it affect electronics?

Electrostatic discharge (ESD) occurs when a sudden flow of electricity transfers between two objects with different electrical potentials. This phenomenon often happens when a charged object comes into contact with an uncharged one. ESD can generate voltage spikes that exceed the tolerance of sensitive electronic components, leading to damage or malfunction. For instance, the ANSI/ESD S20.20-2016 standard highlights that components can fail at voltages as low as 100 volts for the human-body model (HBM) and 200 volts for the charged-device model (CDM). These thresholds demonstrate how even minor ESD events can harm electronics.

The PEG-1 ESD field simulator shows that real-world ESD events occur frequently, with 3-7 discharges per second. Some discharges, such as micro-gap events, have risetimes as low as 10 picoseconds, making them difficult to detect. These rapid and unpredictable occurrences emphasize the need for robust ESD protection diodes in modern devices.

Why consumer electronics require ESD protection

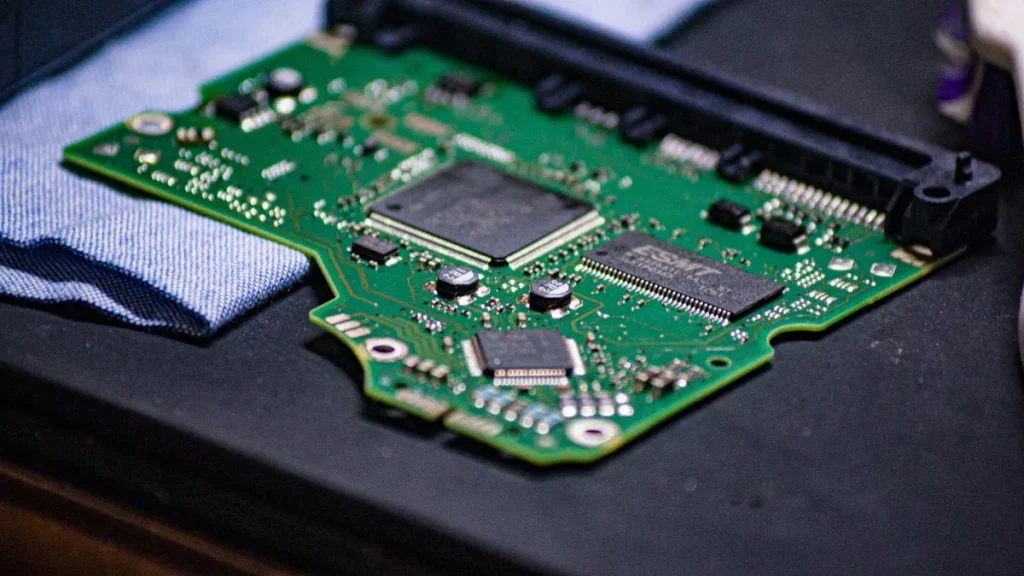

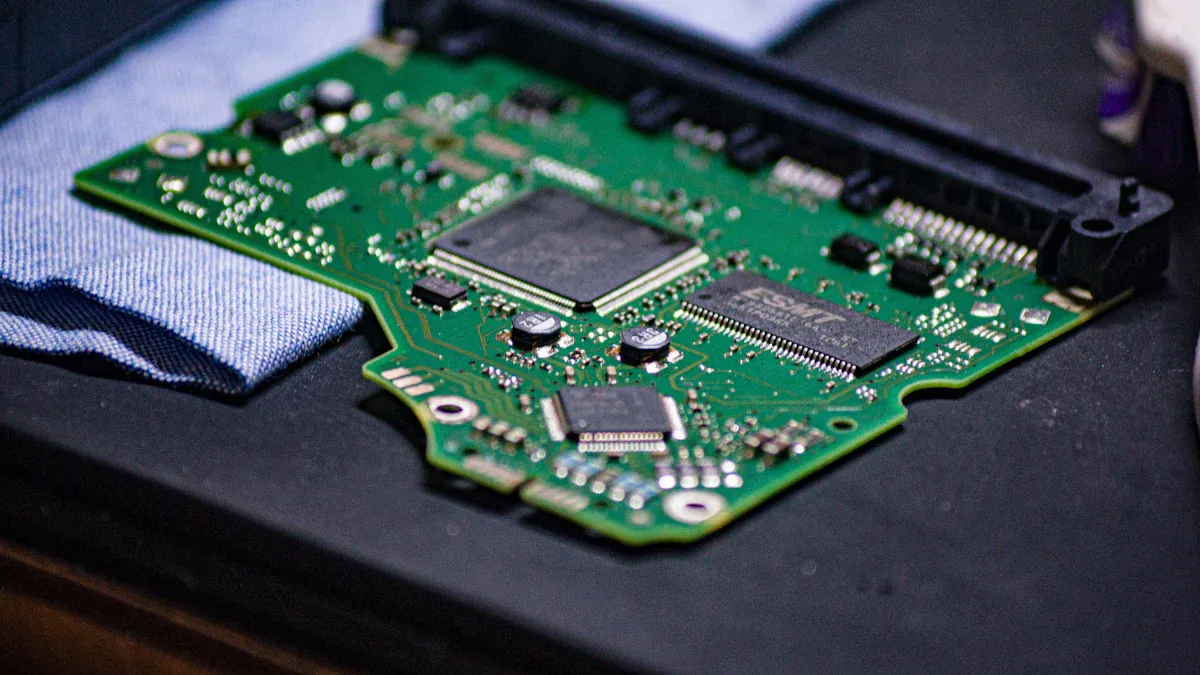

Consumer electronics are highly susceptible to electrostatic discharge due to their compact designs and sensitive components. Devices like smartphones, laptops, and tablets often feature high-speed interfaces and exposed connectors, which are common entry points for ESD. Without proper protection, these devices can experience soft failures, data loss, or even catastrophic damage. Industry studies estimate that ESD-related losses reduce global electronics revenue by an average of 6.5%, underscoring the economic impact of inadequate protection.

ESD protection diodes, such as TPDxE05U06, play a critical role in safeguarding these devices. They act as a shield, redirecting harmful voltage spikes away from vulnerable components. This ensures the longevity and reliability of consumer electronics, even in environments prone to frequent ESD events.

Common ESD vulnerabilities in modern devices

Modern electronics face several vulnerabilities due to their intricate designs and high-speed operations. The following table outlines common types of ESD failures:

|

Type of Failure |

Description |

|---|---|

|

Soft failure |

No physical damage; system malfunctions or stops working, often correctable by rebooting. |

|

Data loss |

No physical damage, but data, software, or firmware corruption occurs, e.g., from nearby lightning. |

|

Catastrophic failure |

Permanent damage that completely disrupts device functionality, caused by melting metal or breakdowns. |

|

Latent defects |

Partial degradation of the IC that continues to function but may lead to critical failures later. |

These vulnerabilities highlight the importance of integrating ESD diodes into circuit designs. By addressing these risks, engineers can enhance device performance and reduce the likelihood of costly repairs or replacements.

Features and Benefits of TPDxE05U06 TVS Diodes

Key features of TPDxE05U06 diodes

TPDxE05U06 TVS diodes offer a range of features that make them ideal for protecting sensitive components in consumer electronics. These diodes are designed with ultra-low capacitance, typically around 0.5 pF, which ensures minimal signal distortion in high-speed applications. Their bidirectional clamping capability allows them to handle both positive and negative voltage spikes, providing comprehensive protection against static discharge.

Another key feature is their fast response time. TPDxE05U06 diodes activate within nanoseconds, effectively redirecting harmful ESD energy away from sensitive components. They also support a wide operating voltage range, making them compatible with various devices, including USB, HDMI, and DisplayPort interfaces. Additionally, their compact package size ensures they occupy minimal board space, which is crucial for modern, space-constrained designs.

How TPDxE05U06 diodes function in ESD protection circuits

In an ESD protection circuit, TPDxE05U06 diodes act as a safeguard between external connectors and internal circuitry. When static discharge occurs, these diodes clamp the voltage spike to a safe level, preventing it from reaching sensitive components. For example, in a USB interface, the diode is placed near the connector to intercept static discharge before it can damage the transceiver.

The diodes achieve this by providing a low-impedance path to ground during an ESD event. This mechanism ensures that the excess energy dissipates safely, protecting the device’s internal components. Their low leakage current also ensures that normal circuit operation remains unaffected, maintaining the integrity of high-speed signals.

Advantages of using TPDxE05U06 diodes in high-speed applications

TPDxE05U06 diodes excel in high-speed applications due to their ultra-low capacitance and fast response time. These characteristics prevent signal degradation, ensuring reliable data transmission in interfaces like USB 3.0, HDMI, and PCI Express. Their ability to handle high-frequency signals without introducing noise or distortion makes them a preferred choice for protecting high-speed devices.

Moreover, these diodes are optimized for modern electronics that require robust ESD protection without compromising performance. Their compact size and compatibility with high-speed interfaces make them suitable for smartphones, laptops, and other portable devices. By integrating TPDxE05U06 diodes, engineers can enhance the durability and reliability of their designs while maintaining optimal signal quality.

Practical Integration of TPDxE05U06 Diodes into ESD Protection Circuits

Best practices for diode placement in circuit layouts

Proper placement of TPDxE05U06 diodes in a circuit layout is critical for achieving optimal ESD protection performance. Engineers should position these diodes as close as possible to potential ESD entry points, such as connectors or exposed interfaces. This placement ensures that voltage spikes are clamped before they can propagate into the system. For example, in a USB interface, the diode should be located near the connector to intercept static discharge effectively.

To enhance reliability, designers should connect the diode to a low-impedance ground plane. This configuration allows the ESD current to dissipate efficiently, minimizing the risk of damage to sensitive components. Additionally, isolating signal lines around the diode can prevent interference and maintain signal integrity. These practices are essential for ensuring robust system-level ESD protection in modern devices.

Guidelines for connecting TPDxE05U06 diodes effectively

Connecting TPDxE05U06 diodes correctly is vital for maintaining the reliability and functionality of the ESD protection circuit. The following guidelines outline effective connection strategies:

-

Select a diode with a clamping voltage slightly above the operating voltage of the circuit but below the voltage rating of the protected components. This ensures that the diode activates only during voltage spikes.

-

Use diodes with fast switching characteristics to quickly clamp transient voltage spikes and protect the system.

-

Choose unidirectional diodes for circuits with one-way signals and bidirectional diodes for applications involving both positive and negative signals.

-

Ensure low capacitance for high-speed circuits to minimize signal distortion and maintain data integrity.

-

Connect the diode in parallel with the signal line, linking one end to the signal path and the other to the ground plane. This configuration provides a direct path for ESD energy to dissipate safely.

-

Verify that the diode can handle continuous current without degradation, ensuring long-term reliability.

-

Balance performance and cost when selecting diodes, especially for critical applications like smartphones or automotive systems.

By following these guidelines, engineers can maximize the effectiveness of ESD protection diodes while maintaining the overall performance of the circuit.

Tips for ensuring compatibility with high-speed interfaces

High-speed interfaces, such as USB 3.0, HDMI, and PCI Express, require careful consideration when integrating TPDxE05U06 diodes. These interfaces operate at high frequencies, making them susceptible to signal distortion if the wrong diode is used. To ensure compatibility, engineers should prioritize diodes with ultra-low capacitance, typically around 0.5 pF. This feature minimizes signal degradation and preserves data transmission quality.

Another important factor is the diode’s response time. TPDxE05U06 diodes activate within nanoseconds, making them ideal for clamping fast voltage spikes without affecting the system’s performance. Additionally, selecting the appropriate package type, such as surface-mount technology (SMT), can help save space in compact designs like wearable devices or IoT applications.

Finally, thorough ESD testing should be conducted to verify the effectiveness of the protection circuit. Testing ensures that the diodes perform as expected under real-world conditions, providing reliable protection against voltage spikes. By implementing these tips, engineers can achieve seamless integration of TPDxE05U06 diodes into high-speed interfaces, enhancing both performance and reliability.

Troubleshooting and Overcoming Challenges

Common issues during installation and how to resolve them

Installing TPDxE05U06 diodes in a circuit can sometimes present challenges. Engineers may encounter issues such as improper placement, incorrect orientation, or mismatched specifications. These problems can reduce the effectiveness of the ESD protection circuit and compromise the device’s reliability.

To address placement issues, engineers should ensure that the diodes are positioned close to external connectors or exposed interfaces. This minimizes the distance between the diode and the potential source of electrostatic discharge, allowing the diode to clamp voltage spikes effectively. Incorrect orientation can be resolved by verifying the diode’s polarity during installation. Bidirectional diodes like TPDxE05U06 simplify this process, as they can handle both positive and negative voltage spikes.

Mismatched specifications often occur when the diode’s clamping voltage exceeds the tolerance of the protected components. Engineers should select diodes with clamping voltages slightly above the operating voltage of the circuit but below the maximum voltage rating of the components. This ensures the diode activates only during an ESD event. Following these practices can help overcome common installation challenges and optimize the performance of the protection circuit.

Testing the effectiveness of ESD protection circuits

Testing is essential to validate the performance of ESD protection circuits. Engineers use standardized methodologies to ensure circuits can withstand electrostatic discharge without failure. The IEC 61000-4-2 standard provides a recognized framework for testing ESD protection circuits. It evaluates the circuit’s ability to handle voltage spikes under controlled conditions, ensuring compliance with industry requirements.

Several testing methods provide quantifiable evidence of circuit performance. ESD testing identifies vulnerabilities in the design, ensuring reliability and long-term durability. It validates the robustness of circuits against electrostatic events, reducing field failures and enhancing device performance. Engineers often simulate real-world ESD events to assess the circuit’s response and verify the effectiveness of the diodes.

For accurate results, testing should include both direct and indirect discharge scenarios. Direct discharge tests evaluate the diode’s ability to clamp voltage spikes at the point of contact, while indirect tests assess its performance in dissipating energy through the PCB ground plane. These methodologies ensure comprehensive protection and help engineers refine their designs for optimal performance.

Avoiding design mistakes with TPDxE05U06 diodes

Design mistakes can compromise the effectiveness of ESD protection circuits. Engineers must follow best practices to avoid common errors when integrating TPDxE05U06 diodes into their designs. Proper placement of diodes at all external connections is crucial to prevent ESD damage. For example, in a medical device project, engineers strategically placed diodes near battery connectors and USB ports to protect against electrostatic discharge. This approach ensured comprehensive protection for sensitive components.

Another common mistake involves neglecting additional protection measures. In some designs, operational amplifiers can complement TVS diodes by providing secondary protection against voltage spikes. Engineers should consider these measures to enhance the circuit’s robustness. Selecting diodes with appropriate specifications is equally important. Ultra-low capacitance diodes like TPDxE05U06 are ideal for high-speed applications, as they minimize signal distortion and preserve data integrity.

Finally, engineers should conduct thorough testing to identify potential design flaws. Testing ensures the diodes perform as expected under real-world conditions, reducing the likelihood of field failures. By following these practices, engineers can avoid design mistakes and create reliable ESD protection circuits for consumer electronics.

Electrostatic discharge (ESD) protection plays a vital role in ensuring the reliability and longevity of consumer electronics. Devices like smartphones, laptops, and IoT systems face constant exposure to ESD risks, making robust protection essential. The global ESD protection circuit market, valued at $3.5 billion in 2021, reflects the growing demand for reliable solutions. With an expected CAGR of 5.7% from 2021 to 2026, this trend highlights the importance of adopting advanced ESD protection technologies.

|

Metric |

Value |

|---|---|

|

Global ESD Protection Circuit Market (2021) |

$3.5 billion |

|

Expected CAGR (2021-2026) |

5.7% |

|

Key Drivers |

Adoption of electronic devices, demand for reliable circuit protection, expansion of semiconductor industry |

TPDxE05U06 TVS diodes offer exceptional features, including ultra-low capacitance and fast response times. These advancements ensure minimal signal distortion and reliable protection against voltage spikes. Recent developments in ESD protection devices have reduced junction capacitance from 1.5 pF to as low as 0.15 pF, enhancing performance in high-speed applications.

Engineers seeking to improve the durability of their designs should consider TPDxE05U06 diodes. Their compact size, compatibility with high-speed interfaces, and proven reliability make them an ideal choice for modern electronics. By integrating these diodes, designers can safeguard their projects and meet the demands of today’s technology-driven world.

1. What makes TPDxE05U06 diodes suitable for high-speed interfaces?

TPDxE05U06 diodes feature ultra-low capacitance (around 0.5 pF) and fast response times. These characteristics prevent signal distortion and ensure reliable data transmission. Their compact size and compatibility with USB, HDMI, and PCI Express interfaces make them ideal for high-speed applications.

2. Can TPDxE05U06 diodes protect devices with multiple exposed interfaces?

Yes, TPDxE05U06 diodes can protect multiple exposed interfaces. Engineers can place these diodes near each interface, such as USB ports or HDMI connectors, to safeguard against ESD. Their bidirectional clamping capability ensures comprehensive protection for both positive and negative voltage spikes.

3. How do TPDxE05U06 diodes handle electrostatic discharge?

These diodes provide a low-impedance path to ground during an ESD event. When a voltage spike occurs, the diode clamps it to a safe level, redirecting the excess energy away from sensitive components. This mechanism prevents damage and ensures device reliability.

4. Are TPDxE05U06 diodes compatible with compact designs?

Yes, TPDxE05U06 diodes are highly compatible with compact designs. Their small package size allows them to fit into space-constrained devices like smartphones, wearables, and IoT systems. This makes them an excellent choice for modern, portable electronics.

5. What testing standards ensure the effectiveness of TPDxE05U06 diodes?

The IEC 61000-4-2 standard evaluates the performance of ESD protection circuits. Engineers use this standard to test TPDxE05U06 diodes under controlled conditions. It ensures the diodes can handle voltage spikes effectively, providing reliable protection for consumer electronics.

See Also

A Comprehensive Overview of AD620AN for TV Power Use

Unveiling LPQ252-CEF: A Solution for Power Efficiency

In-Depth Look at AD1940YSTZ and AD1941YST for Automotive Audio

Exploring ARTESYN NPT42-M for Industrial Power Solutions

Key Programming Techniques for MC9S12XD256 Microcontrollers